Aerial Fiber Optic Cable

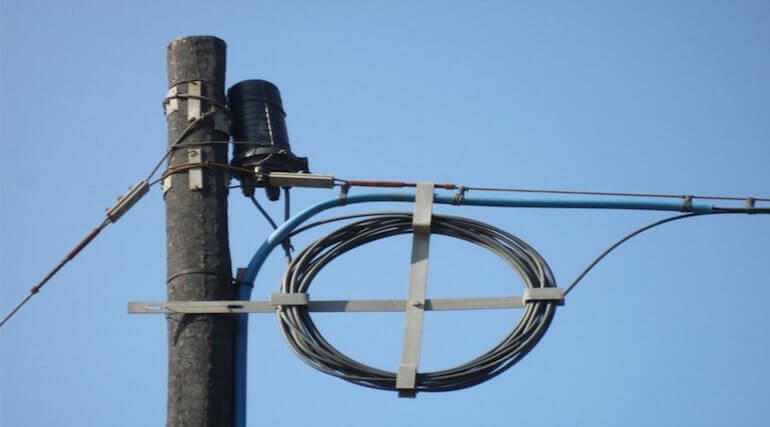

Aerial fiber optic cable is used when installing outside the pole. Adopting aerial fiber optic cables, the aerial construction will allow the installers to reuse the existing pole infrastructure without digging up other roads to bury cables or ducts, and will also save the capital expenditure for the network providers to some degree.

As a professional aerial fiber optic cable manufacturer & supplier, we specialize in designing, manufacturing aerial fiber optic cable, and providing customized services for our customers!

- Excellent waterproof performance, excellent mechanical performance and temperature performance

- Competitive price

- OEM Service can be provided

- 100% quality assurance

Aerial Fiber Optic Cable

Manufactured For Aerial Applications,

Designed And Optimized To Be Suspended In The Air

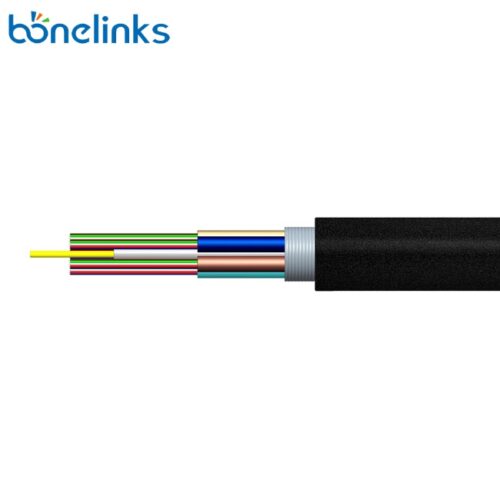

Aerial fiber optic cable refers to a kind of cable that is designed and used for outside plant (OSP) installation between poles by being lashed to a wire rope messenger strand with a small gauge wire.

Aerial outdoor cable is an insulated fiber optic cable, usually containing all the optical fibers needed for a telecommunications line, which is suspended between utility poles or transmission tower, as it can even be lashed to a wire rope messenger strand with a small gauge wire. The strands are tensioned to bear the weight of the cable for the span length, and it is used for any harsh climatic such as ice, snow, water and wind. The aim is to keep the stress on the fiber cable as low as possible while keeping the sling and cable from falling for safety. Generally speaking, aerial optical cables are usually made of heavy sheath and strong metal or aramid strength members, which have excellent mechanical and environmental performance, high tensile strength, light weight, easy installation and low cost.

Aerial Fiber Optic Cable Types

Aerial fiber optic cables can be lashed to a messenger or another cable (common in CATV) or have metal or aramid strength members to make them self-supporting.

According to the installation method, aerial optical cables can be divided into self-supporting aerial fiber optic cable and catenary wire aerial fiber optic cable.

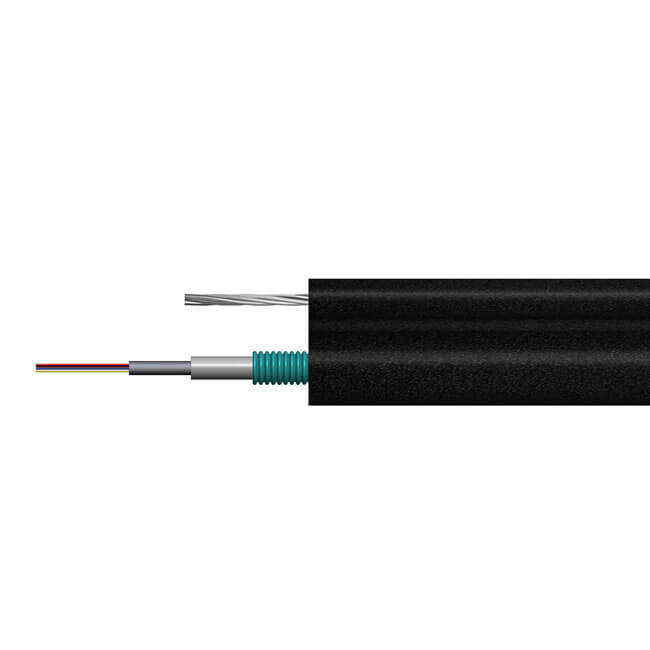

Self-supporting aerial cable: Self-supporting fiber optic cable is connected to an insulating steel or fully insulated messenger to provide support. The self-supporting aerial cable types include all dielectric self-supporting (ADSS) and figure 8 cables. ADSS is an all-dielectric (no metal components inside the cable) self-supporting cable. Usually, ADSS cables are made up of heavier jackets and stronger metal. The figure 8 self-supporting sling is a steel strand, which is metal, and in the structure of the figure 8 cable.

Catenary wire aerial fiber optic cable: A catenary wire aerial outdoor cable is a common outdoor loose-tube cable that can be tied to a sling or another fiber optic cable (common in CATV).

Aerial Fiber Optic Cable Self-supporting Non Metallic

Aerial Fiber Optic Cable Self-supporting Metallic

Aerial Fiber Optic Cable Catenary Wire Non Metallic

Aerial Fiber Optic Cable Catenary Wire Metallic

Find More Aerial Fiber Optic Cable

ADSS All-Dielectric Self-Support Aerial Cable

The ADSS (All-dielectric Self-supporting) optical fibre cable is a kind of aerial fibre optic cable designed to install outdoor applications. It is designed for outside plant aerial and duct applications in local and campus network loop architectures.

Customized Aerial Fiber Cable

For Your Peace of Mind

We go beyond your expectation. Want to make customized aerial fiber cable? With flexibility and expertise being at the core of our comprehensive product customization service, we have a set of processes and services to meet your special requirements. Based on your need and our extensive experience. You name it, we make it!

Customized Materials & Specifications

For Aerial Fiber Cable

No matter what specification for aerial fiber cable, at Bonelinks, You Can Choose Freely For Your Unique Request. We are determined to find a solution for you.

Our knowledgeable representatives are available to address any inquiries about your fiber optic network project. Benefit from competitive pricing for quality products, ensuring your project stays within budget.

- 1 – 288 Core

- Single mode, Multimode

- OS1, OS2,OM2, OM3, OM4…

- G.652D;G.657.A1; G.657.A2 or other Customized Fiber Type

- Self-supporting, catenary wire…

- Metallic, Non Metallic…

- Unitube, MLT…

- Tensile, Crush, Span…

- 1km, 2km, 4km…

- PE, HDPE, AT…

Features and benefits

Faster Connectivity

Aerial outdoor cable ensures fast installation, utilizing existing poles for quicker connectivity compared to time-consuming underground methods like trenching, substantially reducing installation time by up to 50%.

Cost-Effective

Aerial placement proves economical, especially in rural areas, utilizing existing poles and incurring minimal long-term maintenance costs for ADSS outdoor cable.

Lightweight

Aerial cables are portable and easy to manage due to their lightweight, enabling rapid deployment at a rate of 4 to 5 km per day.

Weather-Resistance

Designed for a 25-year lifespan, aerial cables exhibit robustness features, withstanding harsh environmental conditions such as wind, ice loading, rain, and UV exposure reliably. Outdoor Cable boasts low rates of attenuation, making this cable fitting for long distance applications.

Aerial Fiber Optic Cable Price

Discover an unparalleled experience with our ultimate goal of creating an individualized network that remains dependable for years to come. Benefit from our competitive pricing, cutting-edge products, and exceptional customer service.

Aerial Fiber Optic Cable Accessories and Tools

Having the right tools will help save you time and money. Discover the full range of aerial cable accessories at Bonelinks to find everything you need for a successful outdoor installation of your fiber cable. Our aerial hardware is built to withstand different weather conditions, and we have the right hardwire options for all types of aerial installations to ensure your success.

Aerial Fiber Optic Cable Installation Guide: Hardware, Requirements; Methods and Cost

Aerial cables are exposed to various environmental challenges and this is something that should be addressed during the installation process.

Aerial Outdoor Cable Applications

Aerial cables, specifically manufactured for outdoor use, are optimized for suspension in the air. The outer jacket of these cables is enhanced with high-quality materials to withstand harsh weather conditions and prolonged exposure to sunlight. Additionally, the aerial cables feature a ¼” galvanized messenger wire, providing stability in suspended applications that extend from rooftop to rooftop. Cable T.V., outside plant, and telecom applications are a few examples in which aerial cables are often utilized.

Aerial cables are for outside installation on pole line. It can use the original overhead wire and pole infrastructure. This overhead laying method can save a lot of construction costs and shorten the construction period.

CATV & Computer Networks System

Outdoor aerial application

Subscriber Network Systems

Your Trusted Aerial Fiber Optic Cable Supplier

Bonelinks provides network essentials manufactured to the highest standards,

serving as a reliable foundation for your applications.

Innovation, Quality, Service and Responsibility

- Our R&D team, skilled workers, advanced machines, and modern factories can provide our customers with outstanding quality service.

- On the flexibility

- High-quality control standard

- Plenty of Certificates of products and customs

- Professional expert team

- 24/7 Availability

You Ask, We Answer

Aerial installation is a method of installing fiber optic cable by suspending it from poles or other overhead structures.

This type of installation is commonly used in areas where it is not feasible to bury the cable underground, such as in mountainous or urban areas.

In an aerial installation, the fiber optic cable is attached to poles or other structures using clamps, brackets, or other specialized hardware.

The cable is then typically strung between poles or other structures using specialized equipment, such as a bucket truck or a helicopter.

There are two main methods for aerial fiber optic cable installation: the moving reel method and the stationary reel method.

1. Moving Reel Method:

- Used when a cable reel trailer or aerial lift truck can easily move along the pole line without obstructions.

- A one-pass operation that saves time and does not require cable blocks or pull lines, increasing efficiency.

2. Stationary Reel Method:

- Used when laying the cable over an existing lateral cable or encountering obstructions.

- The choice of vehicles and equipment availability also influences this method’s use.

1. When laying aerial optical cable in a flat environment, use the hook to hang it; when laying the aerial optical cable on a mountain or steep slope, use the binding method to lay the optical cable. The optical cable joint should choose a straight pole position that is easy to maintain, and the reserved optical cable is fixed on the pole with a reserved bracket.

2. The optical cable of the aerial pole road is required to make a U-shaped telescopic bend every 3~5 poles, and about 15m is reserved for every 1km.

3. Use galvanized steel pipes to protect the aerial optical cables leading up, and the nozzles of the pipes should be blocked with fireproof mud.

4. Aerial optical cables should hang optical cable warning signs every 4 bars or in special areas such as crossing roads, rivers, and bridges.

5. The intersection of the empty suspension line and the power line should be protected by a trident protection tube, and the extension of each end should not be less than 1m.

6. The pull wires of electric poles near the road should be covered with light sticks, and the length is 2m.

7. In order to prevent the induced current from the suspension wire from hurting people, each pole pull wire is required to be electrically connected to the suspension wire, and each pull wire position should be installed with a pull wire ground wire. The suspension wire is required to be directly connected with a lining ring and grounded directly at the terminal.

8. The aerial optical cable is usually 3m above the ground. When entering the building, it must pass through the U-shaped steel protective sleeve on the outer wall of the building, and then extend downward or upward. The aperture of the optical cable entrance is generally 5cm.

The minimum order length of fiber optic cable is 1km. Because the outside diameter needs to be adjusted before producing.

This process will waste dozens of meters of raw material.

Yes. We have Fujikura, Corning SMF 28e, and other brands fiber to choose from.

Yes. As long as we confirm the Pantone color code, we can produce the sheath color you request.

Yes. We will have a dedicated process engineer to interface with you to understand the specific situation and give our production advice.

Yes. We can print company information or logos on fiber optic cables upon request.

Under 100 km, it takes 4-5 days to produce. under 500 km, it takes 7-10 days to produce.

All fiber optic cables will come with a test report. If you encounter any quality problems, we replace them with new ones free of charge.

We have a special laboratory for high temperature, salt spray and vibration testing.

A supplier provides products,

but we care about your business.

If you do not find aerial fiber optic cables that can meet your requirements, please contact us as we might have a solution available.