Ruggedised Fibre Patch Leads

Experience superior connectivity with our ruggedized fibre patch leads.

- Flexible and compact, they fit in tight spaces.

- Crush and kink resistant, ensuring uninterrupted data transmission.

- Twice as strong as standard duplex patch cables, providing maximum durability.

- Reduced risk of damage during installation and long-lasting performance.

Ruggedised Fibre Patch Leads

Extra Protection with Built-in Metal Armor

Ruggedised Fibre Patch Leads

Our Ruggedised Fibre Patch Leads are the ultimate solution for demanding environments, providing a robust alternative to standard patch cables. They are designed with a double sheathed flat twin configuration, consisting of two simplex semi-tight buffered cables surrounded by aramid yarn and encased in an additional LSZH sheath. These Ruggedised Fibre Patch Leads offer exceptional durability, flexibility, and compactness.

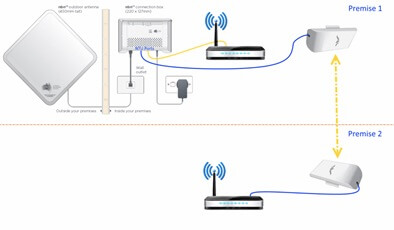

The utilization of ruggedized fiber patch leads is optimal for splicing FTTH drops in the ONT/NID. In colder climates, indoor cordage can stiffen and maintain cable memory. However, these ruggedized fiber patch cables preserve their flexibility even under the harshest conditions. These assemblies employ bend-insensitive optical fibers, effectively resolving bend-radius concerns within the NID. Additionally, these patch cords are well-suited for use in outside plant cross-connect cabinets.

Ruggedized Fibre Patch Leads Vs Standard Fibre Cables

Ruggedized fibre patch leads provide a superior solution for applications requiring reliable and durable fibre optic connectivity in demanding environments, offering enhanced protection compared to standard fibre cables.

| Performance Parameter | Ruggedised Fibre Patch Leads | Standard Patch Cables |

|---|---|---|

| Materials | Reinforced connectors, robust outer jackets | Standard connectors and outer jackets |

| Design Features | Additional protective layers, armored design | Standard design |

| Environmental Resistance | Enhanced resistance to moisture, dust, and chemicals | Standard resistance to environmental factors |

| Torsion | Standard: IEC-60794-1-2-E7 and TIA/EIA-455-85 Length of fiber optic cable tested: 4 m Tension load: 30 N (according to the diameter of the fiber optic cable) Rotation frequency: 1 turn per minute for a total of 10 turns Duration: 5 minutes | Standard: IEC-60794-1-2-E7 and TIA/EIA-455-85 Length of fiber optic cable tested: 4 m Tension load: 15 N (according to the diameter of the fiber optic cable) Rotation frequency: 1 turn per minute for a total of 10 turns Duration: 5 minutes |

| Impact Resistance | Standard: IEC-60794-1-2-E4/TIA/EIA-455-25 Hanging hammer weight: 2 Kg Impact frequency: 30 times / min Duration: 5 minutes Suspension height: 150±5mm | Standard: IEC-60794-1-2-E4/TIA/EIA-455-25 Hanging hammer weight: 1 Kg Impact frequency: 30 times / min Duration: 5 minutes Suspension height: 150±5mm |

| Min Static Bend | 10D | 10D |

| Min Dynamic Bend | 20D | 20D |

| Tensile Load (long term) | 150N | 150N |

| Crush (long term) | 2000N/100MM | 1000N/100MM |

| Crush (short term) | 3000N/100MM | 1500N/100MM |

| Operating Temperature | -20℃ to 75℃ | -20℃ to 75℃ |

Ruggedised Fibre Patch Leads Features

Are you operating in harsh environments or industrial settings with extreme temperatures, vibrations, or exposure to chemicals? Do you require reliable fiber optic connectivity in outdoor installations subject to weather elements, UV radiation, or physical stress? Are you in the military, defense sector, or dealing with high-density installations where durability and resilience are critical?

If you answered “yes” to any of these questions, choosing ruggedized fibre patch leads is the ideal solution. They provide the durability, protection, and reliability needed to withstand challenging conditions, ensuring uninterrupted connectivity. Don’t compromise on performance—opt for ruggedized fibre patch leads for dependable and robust fibre optic connections.

Robust Construction

The double sheathed flat twin design and aramid yarn reinforcement provide superior strength and protection against kinking and crushing during installation and handling.

Crush and Kink Resistant

Our fiber patch leads are engineered to withstand the rigors of frequent handling and harsh conditions, offering excellent resistance to crushing and kinking.

Compliance with Building Regulations

Available in flame retardant PVC or LSZH sheaths, our fiber patch leads comply with the strictest building regulations for safety.

Twice the Strength

These fiber patch cables are twice as strong as standard duplex patch cables, ensuring long-lasting performance and reduced risk of damage.

Flexible and Compact

Despite their enhanced durability, these patch leads remain highly flexible and compact, allowing for easy installation in tight spaces.

Enhanced Protection

The tight-buffered fibres in our ruggedized patch cables are strengthened with aramid yarns and jacketed with polyurethane, making them resistant to water, sunlight, chemicals, and abrasions.

Ruggedised Fibre Patch Leads Application

Installing ruggedized fiber patch leads is crucial in challenging environments. These cables are perfect for indoor and outdoor use, including data centers where underfloor installation prevents fiber cable damage. Their flexibility and durability make them ideal in harsh conditions like dust, extreme temperatures, and potential rodent damage.

Office LAN Connections

Ruggedised patch leads are perfect for use in office environments where frequent handling and movement are common, ensuring reliable and durable connectivity.

Internal Point-to-Point Links

Ruggedised patch leads are recommended for internal runs that require a stiffer and more rugged cable, providing robust connectivity between network devices.

Industrial Applications

In industrial settings, ruggedised patch leads offer enhanced resistance to potentially harmful elements, making them ideal for reliable data transmission in challenging environments.

Comprehensive Fiber Optic Supplier Meet Your Needs

What Make Our Ruggedized Fiber Patch Cable Unique

As one of the most professional ruggedized fiber optic patch cord suppliers and manufacturers, no matter what specifications of fiber optic patch cables you want, you can choose freely for your unique request at Bonelinks.

- LC, LC/APC, SC, SC/APC, ST, FC, and FC/APC fiber optic connectors options

- Tailored lengths and personalized colors are available

- All assemblies are 100% tested

- Meeting industry standard

- Backed by a 10-year warranty

- Singel mode OS2 and multimode OM1, OM3, and OM4 fiber options

- Environmentally stable, low insertion loss, minimal back reflection

- Stock and Make-to-Order

Your Reliable Ruggedised Fibre Patch Leads Supplier

Innovation, Quality, Service and Responsibility

Enhanced Durability

Our ruggedized fibre patch leads are crafted with meticulous attention to detail, setting the standard for excellence in the industry. We prioritize uncompromising quality, ensuring that our patch leads not only offer enhanced durability but also deliver exceptional performance and reliability.

Superior Quality

We maintain the highest standards of quality and craftsmanship in our ruggedized patch leads. They undergo rigorous testing, including crush resistance, kink resistance, and tensile load tests, ensuring they can withstand demanding environments without compromising performance.

Customization Options

Tailor your network infrastructure precisely to your needs with our versatile ruggedized patch leads. Choose from various lengths, connector types (LC, SC, ST, etc.), and jacket materials (LSZH, PVC, etc.) to seamlessly integrate them into your setup while maintaining optimum performance.

Expert Support

Our dedicated team of fibre optic experts is always ready to provide you with exceptional support. Whether you need assistance with product selection or post-purchase support, we offer personalized guidance, technical expertise, and timely responses to ensure your connectivity needs are met.

Trusted and Proven

Our ruggedized fibre patch leads have earned the trust of customers in diverse industries. From industrial facilities to military installations, they have demonstrated their reliability and performance in scenarios, providing uninterrupted connectivity even in the most demanding situations.

10-Year Warranty

We stand behind the quality and reliability of our patch leads with a 10-Year Warranty, ensuring peace of mind for our customers.

Reliable and Resilient: Ensuring Quality with Ruggedised Fibre Patch Leads

Rigorous Raw Materials Selection and Inspection

We carefully select and inspect raw materials renowned for enhanced durability, flexibility, and resistance to environmental factors. We conduct thorough inspections on all incoming raw materials to guarantee they meet our stringent quality standards. Our optical fibres undergo meticulous assessment for uniformity, tensile strength, and attenuation. Similarly, connectors are scrutinized for physical damage and compatibility to ensure their suitability for rugged applications.

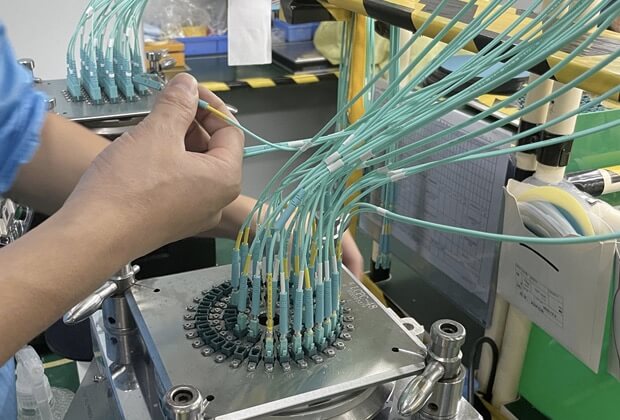

Precise Production Process Control

To achieve consistent quality, our fibre optic patch leads are manufactured following a strict production process. We exercise close monitoring over every aspect, including polishing, termination, and assembly. Specialized equipment is utilized to ensure correct fibre alignment and polished connectors that adhere to the required rugged standards.At Bonelinks, we adhere to implementing a rigorous quality control process throughout our manufacturing.

Comprehensive Durability Testing

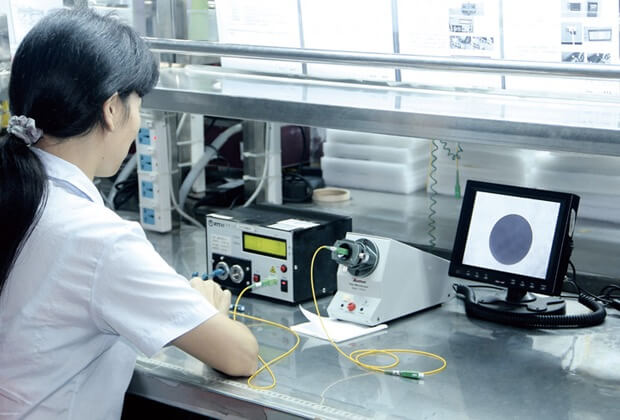

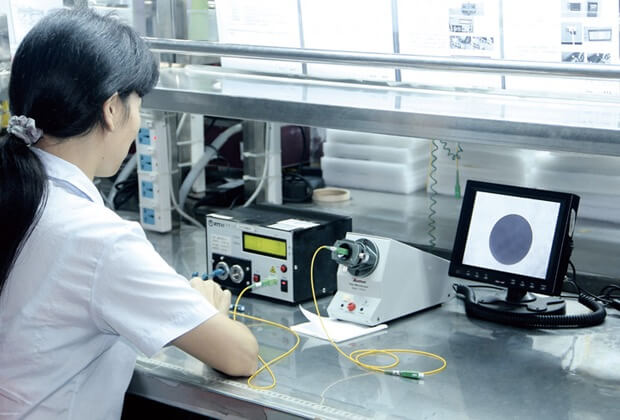

We conduct comprehensive testing to ensure our fibre patch leads surpass ruggedness requirements. Our state-of-the-art testing equipment measures crucial parameters like tensile strength, crush resistance, and impact resistance. Through advanced testing procedures, including precise measurement of insertion loss, return loss, and other performance metrics, we guarantee the durability of our patch leads. Rigorous tests such as tensile strength and temperature cycling identify potential weaknesses, ensuring our products withstand demanding conditions.

Thorough Final Inspection

Before leaving our facility, each finished patch lead undergoes a meticulous final inspection. Our experts conduct visual assessments to verify that the patch lead meets both customer specifications and our uncompromising quality standards. Furthermore, specialized testing equipment is employed to ensure that the insertion loss and return loss fall within the required ruggedness parameters.

A supplier provides products,

but we care about your business.

If you do not find a product that can meet your requirements, please contact us as we might have a solution available.