Fiber Optic Cable Price

How much is fiber optic cable cost per foot?

When it comes to choosing fiber optic cabling for your network, there are several factors to consider, including the type of optical fibers used, the number of strands in the cable, and whether you need single mode or multi mode fiber. But another important consideration is the cost of the cable, which is typically measured in terms of fiber optic cable price per foot.

How much does a fiber optic cable cost? Broadly speaking, fiber optic cable price is ranging from $0.2 per meter to $3 per meter ($0.06 per foot to $0.92 per foot).

It is a rough question. The cost of fiber optic cable can vary widely depending on a number of factors, such as the type of glass or plastic fiber used, the number of strands in the cable, and the distance the cable needs to cover. Generally speaking, multi mode fiber is less expensive than single mode fiber, but it’s also limited to shorter distances and lower bandwidth. Outdoor fiber optic cables are designed to withstand harsh weather conditions and are generally more expensive than indoor cables.

Different small parameters of the same type of optical cable also lead to price differences. For example, the bow type drop cable is generally a G657A cable, and the price is about $0.025/m to $0.035/m. The price of 3.0mm diameter G652 optical fiber indoor cable is about $0.2/m.

So, Before you check out the fiber optic cable price, might have to ask yourself:

- G657A1, G652D…

- OM1, OM2…

- For indoor or outdoor?

- How many fibers are inside?

- Where it is applied to? For different cable applications, the cable structure is various.

What is the installation cost for fiber optic cabling?

In addition to the cost of the cable itself, you also need to factor in the cost of fiber optic installation. This can also vary widely depending on the complexity of the installation, the distance the cable needs to cover, and whether you’re using existing conduits or need to install new ones.

- The estimated cost of installing fiber optic cable is $1 to $6 per 30 cm (depending on the fiber counts) plus the cost of connecting hardware and terminations.

- The cost of wiring an entire building or facility with fiber is difficult to estimate because there are many variables at play.

- The U.S. Transportation Research and Innovative Technology Administration (RITA) provides fiber optic cable installation costs for a variety of projects. Please note that these projects can be much larger than a typical enterprise.

fiber optic cable Price

fiber optic cable price per foot

It’s essential to consider the long-term benefits of fiber cables and the cost implications for your specific needs. You can contact a professional to discuss the different options and get a quote for your project.

How to Save Fiber Optic Cable Cost?

We’ll Handle Everything

From Star To Finish

High-quality products

help save on the costs of maintaining fiber cable

Materials used in optical cables are the key to the service life of optical cables. Bonelinks has always implemented the concept of quality first and attaches great importance to the quality control of raw materials. When designing products, we take into account how to help customers reduce costs, solve product reliability from the source, value raw material quality control and innovative research and development, and improve product quality, thereby reducing the overall purchase cost of customers at the very beginning.

Raw materials

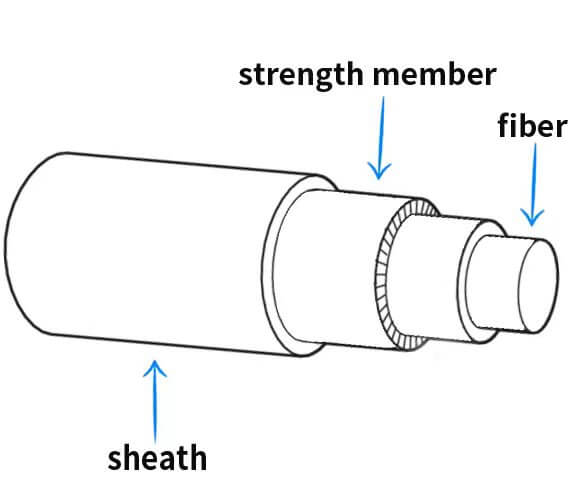

Optical fibers are often made into cables of different structures. Because the optical fiber itself is relatively fragile and easy to break, if it is in direct contact with the outside world, it is easy to produce contact scars or even be broken. There are many types of optical cables, but no matter what their specific structure is, they are composed of optical fiber, sheaths and strengthening members.

1

Fiber optic

Optical fiber is the core raw material in optical cable, which affects the loss and attenuation of optical cable transmission. In the production of optical cables, optical fiber is the main production cost, accounting for about 50%. Generally speaking, the better the quality, the smaller the loss, the less attenuation, and the higher the price.

2

Sheath

The outer sheath materials of indoor optical cables are mainly divided into: PVC, flame-retardant PVC, LSZH, and flame-retardant LSZH. LSZH sheathing material is a material that does not produce a lot of smoke and toxic gases when it catches fire. This material is more expensive than PVC. The price of flame-retardant sheathing varies according to its flame-retardant grade.

3

Strengthening member

The strengthening member plays the role of bearing the tension of the optical cable, usually in the center of the cable core, and sometimes arranged in the sheath. Steel wires or non-metallic materials such as aramid fiber (Kevlar) with high Young’s modulus are usually used as reinforcement components. Kevlar is the patented product name of para-aramid fiber developed by DuPont in the United States, and its price is relatively high. In addition to DuPont in the United States, the main aramid producers include Japan’s Teijin and South Korea’s Cologne, and their prices are lower than DuPont’s.

Lean manufacturing principles

help streamline operations and reduce costs

The ability to produce 25-year quality assurance cables is not the ultimate goal for bonelinks, but rather the starting point for our paranoia about strict quality control. The service life of a fiber optic cable is greatly influenced by the environment in which it is laid, but the structure, component materials and production process are all important factors in giving the cable a strong life, and Bonelinks understands this.

It is well known that fiber optic cables are able to serve as a communication medium because of the refraction of the optical signal inside the fiber. By adding a protective layer to the optical fiber to enable it to transmit signals stably in unused environments, the fiber optic cable is empowering the fiber. To ensure that the optical signal can be transmitted quickly in various complex environments, Bonelinks strictly controls and tests the attenuation of the fiber during the production steps, and designs and adds the necessary structural elements to the overall structure of the fiber optic cable, so that the fiber optic cable maintains stable mechanical properties during the deployment process.

manufacturer

The technological process of optical cable production is as follows: fiber coloring, fiber tight buffering, fiber ribboning, fiber testing, loose tube fiber sheathing, fiber quality control, tight buffer sheathing, ribbon sheathing, fiber stranding, fiber jacketing, fiber armoring, jacket printing and final testing. The automation degree of production equipment, the completeness and accuracy of test instruments, the proficiency of operators, the quality control ability of the factory and the lean production site management ability all affect the quality and price of optical cable products.

1

Provide customized solutions

Bonelinks can work with customers to develop customized solutions that meet their specific needs. This could involve creating cables that are tailored to specific lengths, sizes, or specifications, which can help reduce waste and save on costs.

2

Streamline production processes

We can implement process improvements to optimize production and reduce waste, which can ultimately lead to lower costs for customers.

Efficient packing and shipping solutions

optimize fiber cables transportation costs

According to the performance of the optical cable and the size of the equipment, Bonelinks makes reasonable packaging and transportation solutions , so as to achieve economical delivery on the premise of safety and no damage, thereby reducing the cost of customers.

packing and shipping

Reducing just a quarter of an inch of the packing could translate into substantial saving along the shipping process. It would imply that more number of parcels can be stacked into a truck which in turn will help to reduce the number of truckloads. In the long run, it could lead to lesser costs, less weight, fewer truckloads, and less fuel.

1

Minimizing damage during shipping

Proper packing of fiber cable can help prevent damage during transit, reducing the need for costly repairs or replacement of the cable.

2

Maximizing space utilization

Compact and efficient packing methods can help maximize the use of space in shipping containers, reducing the need for additional containers and associated costs.

3

Minimizing shipping costs

By optimizing packing methods and selecting the most cost-effective shipping options, overall shipping costs can be reduced.

Professional consult team

help spend your money where it is needed

Bonelinks will recommend suitable products to customers instead of expensive products, so as to solve the real needs of customers and reduce customer costs.

Professional

Sometimes customers will directly indicate the item number of fiber optic cable they need to purchase, but Bonelinks will give a purchase suggestion after understanding the environment the customer needs to use from a professional perspective. For example, the customer once want to purchase the GYTA53 optical cable, and after communication with customer, Bonelinks know that the construction environment is to put the optical cable in a 110 U-PVC pipe, and then bury it in the ground. The pipe is about 50 cm away from the wall, and there are no heavy objects and no vehicles passing by. According to the customer’s description, in fact, he only needs to use the GYTA optical cable. If GYTA53 is used, it is unnecessary, and the prices of these two optical cables are far from each other. Customers finally select GYTA optical cable.

1

Providing expert advice

Bonelinks can provide expert advice on the most cost-effective fiber cable solutions for the customer’s specific needs. This includes recommendations on cable type, cable length, and installation method, among other factors.

2

Offering technical support

We can offer technical support to customers, assisting with issues such as cable installation, testing, and maintenance. This can help customers avoid costly mistakes and ensure fiber cable system operates at peak efficiency.

your trusted partner

Bonelinks believe customers should not be charged more to receive exactly what they need. For that reason, we offer our custom fiber cabling at standard prices.

Innovation, Quality, Service and Responsibility

- Our R&D team, skilled workers, advanced machines, and modern factories can provide our customers with outstanding quality service.

- On the flexibility

- High-quality control standard

- Plenty of Certificates of products and customs

- Professional expert team

- 24/7 Availability

You ask, we answer

The unit cost of using copper cables is much lower than that of fiber optic cables. The cost of copper cables is 2-5 times lower than that of optical cables of the same length. In a 1,000-node cluster, hundreds of copper cables may be required, which translates to savings of hundreds of thousands of dollars. If you switch to a larger data center, the cost savings can run into millions of dollars.

However, fiber optic cable is a better economical option in the long run, because there are hidden costs, including maintenance, interference, risk of tampering and replacement cost, etc.

The minimum order quantity of fiber optic cable is 1km. Because the outside diameter needs to be adjusted before producing.

This process will waste dozens of meters of raw material.

Yes. As long as we confirm the Pantone color code, we can produce the sheath color you request.

Yes. We can print company information or logos on fiber optic cables upon request.

Under 100 km, it takes 4-5 days to produce. under 500 km, it takes 7-10 days to produce.

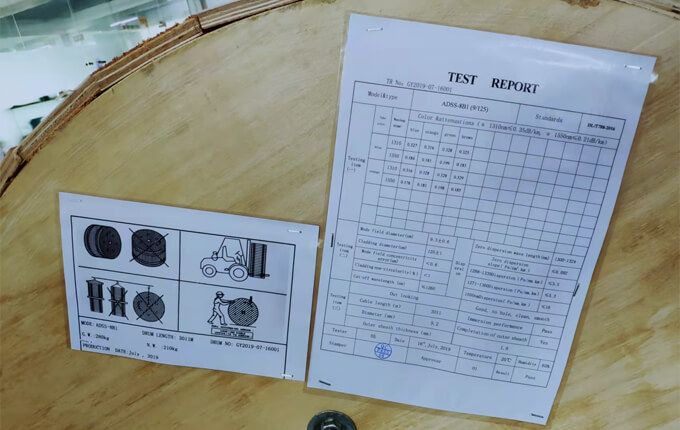

All fiber optic cables will come with a test report. If you encounter any quality problems, we replace them with new ones free of charge.

A supplier provides products,

but we care about your business.

If you do not find a product that can meet your requirements, please contact us as we might have a solution available.