Fiber Heat Shrink Tube: Protecting and Strengthening Fiber Optic Splicing

Heat shrink tubing is a heat shrinkable product. Heat shrinkable products are products which, as the name says, shrink when they are exposed to heat. These products are made by stretching plastics such as polyolefin during the production process.

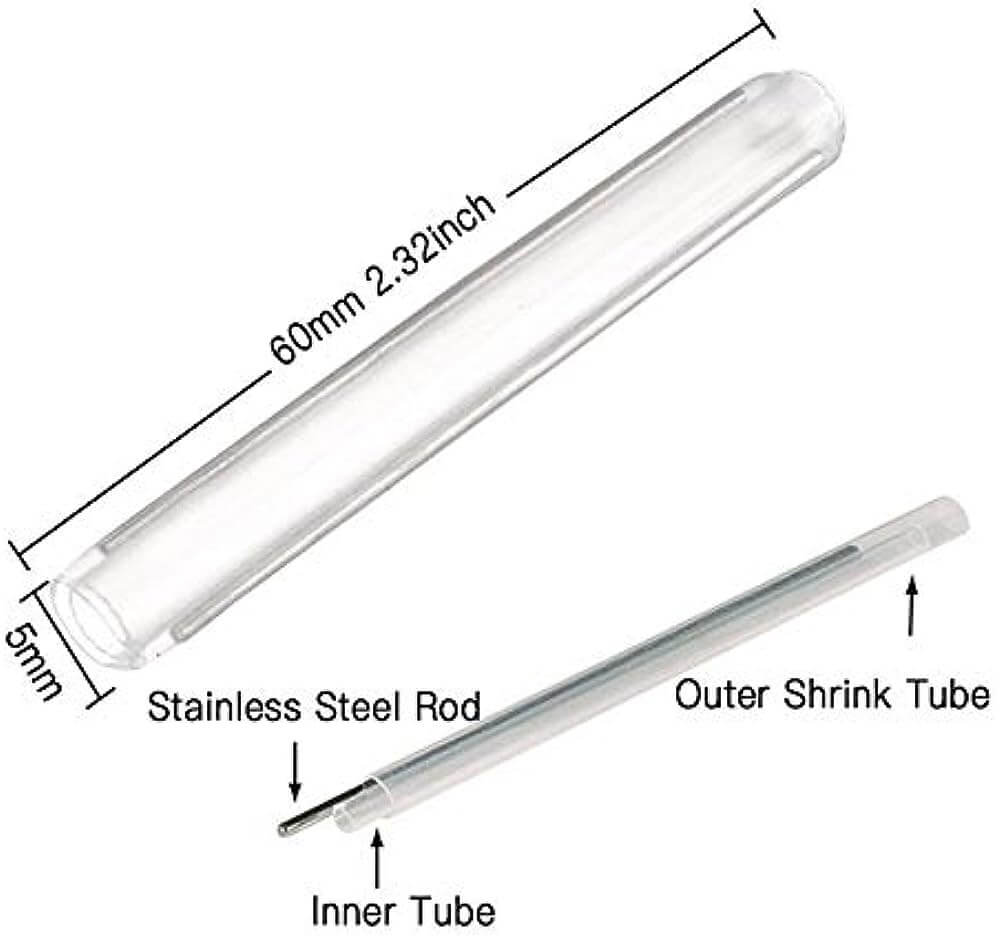

Optic Fiber Heat Shrink Tube is a vital component used to safeguard fiber optic splicing elements. It is composed of cross-linked polyolefin, a hot melt tube, and a steel rod. This tube is designed to provide protection and structural support for fiber optic splicing. To rebuild the coating of fiber to provide mechanical strength at the fusion joint area and keep optical transmission properties. Its inner thermal fusion tube, made of a high-quality polymer, ensures smooth and bubble-free shrinkage. The cross-linked polyolefin offers temperature resistance, strength, and elongation properties. The steel rod prevents warping and damage to the internal fiber during high-temperature heating.

- Steel rod: Stabilize and protect the connection

- Inner tube: Shrink when heated to make the connection

- Outer tube: Shrink around the steel rod and the inner tube, to keep the steel rod and the inner tube tightly together.

| Large Single Fiber Heat Shrink Tube | ||||||

|---|---|---|---|---|---|---|

| Splice Protection Sleeves (After Shrinking) | Fusion Tubing | Steel Rod | Pack | |||

| Outer Diameter (mm) | Length (mm) | Inner Diameter (mm) | Length (mm) | Outer Diameter (mm) | Length (mm) | Pcs/Bag |

| 2.9±0.1 | 60±0.5 | 1.5±0.1 | 60±0.5 | 1.5 | 55 | 100 |

| 2.9±0.1 | 45±0.5 | 1.5±0.1 | 45±0.5 | 1.5 | 40 | 100 |

| 2.9±0.1 | 40±0.5 | 1.5±0.1 | 40±0.5 | 1.5 | 35 | 100 |

| Standard Single Fiber Heat Shrink Tube | ||||||

|---|---|---|---|---|---|---|

| Splice Protection Sleeves (After Shrinking) | Fusion Tubing | Steel Rod | Pack | |||

| Outer Diameter (mm) | Length (mm) | Inner Diameter (mm) | Length (mm) | Outer Diameter (mm) | Length (mm) | Pcs/Bag |

| 2.6±0.1 | 60±0.5 | 1.5±0.1 | 60±0.5 | 1.2 | 55 | 100 |

| 2.6±0.1 | 45±0.5 | 1.5±0.1 | 45±0.5 | 1.2 | 40 | 100 |

| 2.6±0.1 | 40±0.5 | 1.5±0.1 | 40±0.5 | 1.2 | 35 | 100 |

| Small Single Fiber Heat Shrink Tube | ||||||

|---|---|---|---|---|---|---|

| Splice Protection Sleeves (After Shrinking) | Fusion Tubing | Steel Rod | Pack | |||

| Outer Diameter (mm) | Length (mm) | Inner Diameter (mm) | Length (mm) | Outer Diameter (mm) | Length (mm) | Pcs/Bag |

| 2.4±0.1 | 60±0.5 | 1.4±0.1 | 60±0.5 | 1 | 55 | 100 |

| 2.4±0.1 | 45±0.5 | 1.4±0.1 | 45±0.5 | 1 | 40 | 100 |

| 2.4±0.1 | 40±0.5 | 1.4±0.1 | 40±0.5 | 1 | 35 | 100 |

| 2.2-2.3 | 45±0.5 | 1.2±0.1 | 45±0.5 | 1 | 40 | 100 |

| Micro Single Fiber Heat Shrink Tube | ||||||

|---|---|---|---|---|---|---|

| Splice Protection Sleeves (After Shrinking) | Fusion Tubing | Steel Rod | Pack | |||

| Outer Diameter (mm) | Length (mm) | Inner Diameter (mm) | Length (mm) | Outer Diameter (mm) | Length (mm) | Pcs/Bag |

| 1.5-1.6 | 25±0.5 | 0.6±0.1 | 25±0.5 | 0.6 | 25 | 100 |

| 1.5-1.6 | 30±0.5 | 0.6±0.1 | 30±0.5 | 0.6 | 30 | 100 |

| 1.5-1.6 | 35±0.5 | 0.6±0.1 | 35±0.5 | 0.6 | 35 | 100 |

Features

- High-quality material: Made from cross-linked polyolefin, hot fusion tubing, and stainless reinforced steel rod (quartz or ceramic).

- Sealing structure: Ensures reliable splicing performance in diverse temperature and humidity environments.

- Transparent plastic tube and stainless steel rod: Provides visibility and strength for protecting fusion fiber optic splices.

- Clear sleeve: Easy to detect splice before shrinkage.

- Heat-activated memory: Sleeves shrink tightly under heat, excluding air and firmly holding the rod in place.

- Customizable color options: Conveniently choose the color of the optical fiber splice protector for personalized installations.

Benefits

- Excellent heat resistance: Fusion splice protection sleeve is designed to withstand high temperatures and are highly resistant to heat and flames.

- Durability: These tubes are made from high-quality material that provide excellent protection for optic fiber cables.

- Moisture resistance: fusion splice protection sleeve is highly resistant to moisture and can protect cables from water and other liquids.

- Easy to use: Fusion splice protection sleeve is easy to install and require no special tools or equipment.

- Preserves optical transmission performance: Ensures the optical fiber’s transmission capabilities remain intact.

- Reliable protection: Provides a secure safeguard for splicing.

- Stress prevention: Effectively prevents stress on the splices during field and factory operations.

- Abrasion prevention: Protects delicate glass fibers from abrasion, ensuring the splices remain intact and secure.

Function

- Cable Protection: Optic fiber heat shrink tubes are used to protect cables from environmental factors, including moisture and heat. These tubes provide an additional layer of protection to the optic fiber cable, which can help to extend the lifespan of the cable and maintain its performance. The tubes are also resistant to UV rays, which can cause cable jackets to become brittle and crack over time.

- Splicing and Termination: Optic fusion splice protection sleeves are commonly used in splicing and termination applications. When two optic fiber cables are spliced together, a heat shrink tube is used to protect the splice point from external factors that can cause signal loss or damage. The same is true for termination points, where the tube is used to protect the exposed ends of the optic fiber cable.

- Insulation: Optic fusion splice protection sleeve provides excellent insulation for optic fiber cables. They are used to protect the cables from external heat sources that can cause signal loss or damage. The tubes are also used to prevent water penetration, which can affect the performance of the cable.

- Repair: Fusion splice protection sleeve is used to repair damaged optic fiber cables. When a cable is damaged, the heat shrink tube is used to cover the damaged area and protect the cable from further damage. The tube also helps to maintain the integrity of the cable and prevent signal loss.

Application

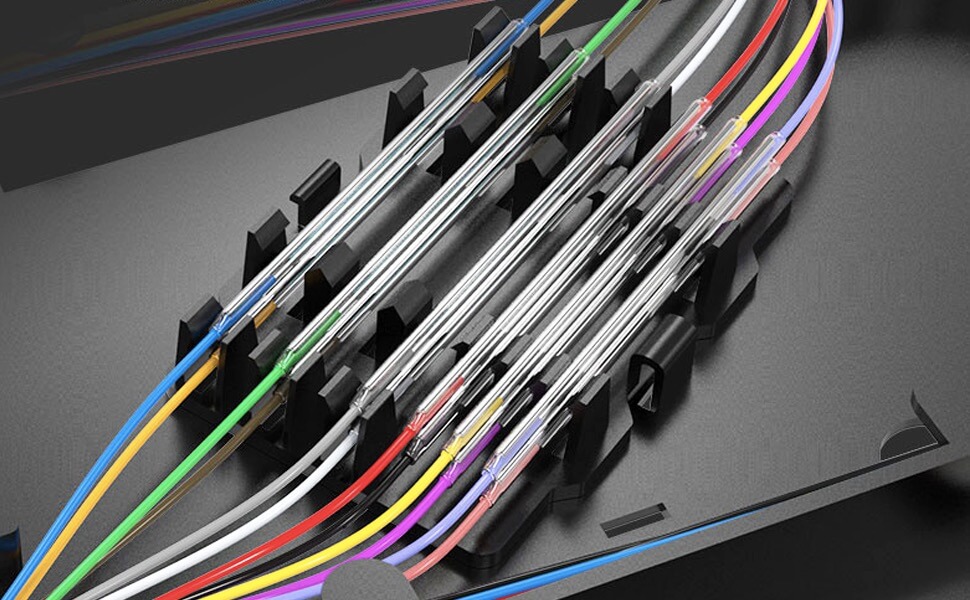

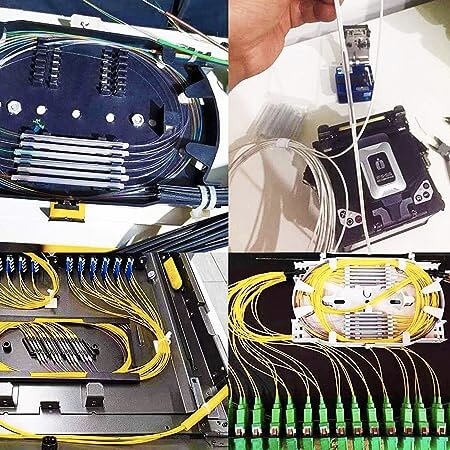

The Fiber Optic Fusion Protection Tube finds wide usage in various communication fiber optic equipment, such as splice boxes, terminal boxes, distribution boxes, and joint boxes. Its primary purpose is to protect the splice point while enhancing the mechanical strength of the fiber. By minimizing the risk of fiber damage during installation, it ensures reliable and durable connections. Moreover, the transparent nature of the tube enables easy visualization of the fiber fusion during the splicing process.

- Fiber Optic Cables: Fusion splice protection sleeve is used in the production of fiber optic cables. The tubes are used to protect and insulate the fiber optic connectors and splices. The heat shrink tube is slid over the connector or splice, and then it is heated to shrink the tube tightly around the connector or splice. This creates a strong, protective seal that prevents moisture, dust, and other contaminants from entering the connector or splice.

- Telecommunications: Fusion splice protection sleeve used in telecommunications to protect and insulate fiber optic connectors and splices. They are used in applications such as local area networks (LANs), wide area networks (WANs), and fiber to the home (FTTH). The tubes are also used to repair damaged fiber optic cables, allowing for a quick and easy fix to any broken cables.

- Data Centers: Fusion splice protection sleeve is used in data centers to protect and insulate fiber optic connectors and splices. They are used to connect servers, storage devices, and other network equipment, ensuring a high-speed, reliable data transmission. The tubes are also used in data center upgrades, allowing for easy installation of new fiber optic cables and connectors.

Packing

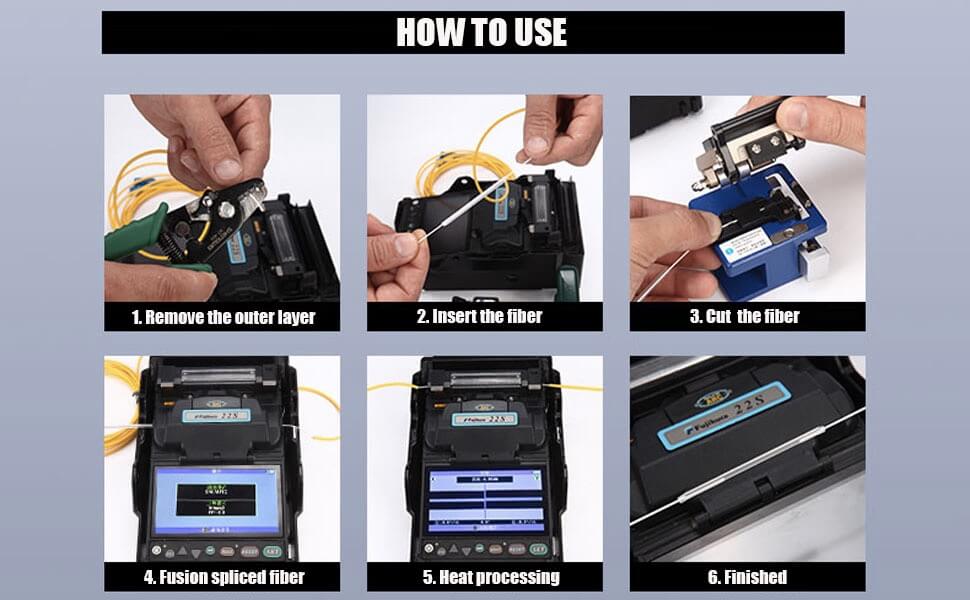

Utilizing the Fusion Protection Tube

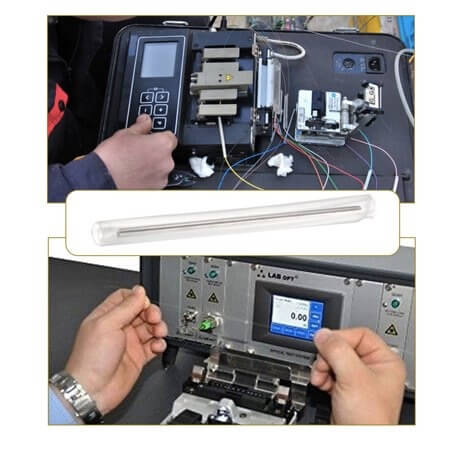

To use the Fiber Optic Fusion Protection Tube in a fusion splicing machine, the outer skin of the fiber optic cable must first be peeled. The fiber optic cable is then fixed, paying attention to the core bundle tube. The optical fiber is then peeled and passed through the Fiber Optic Fusion Protection Tube, making sure to separate the different colored fibers. The power of the fiber optic fusion splicing machine is then turned on, and the appropriate fiber optic fusion mode is selected. The prepared fiber optic endface is cut according to the fiber, and the windshield is opened to remove the fiber from the fiber optic fusion splicer. The fusion splice protection sleeve is then moved to the location of the fiber fusion splice point, put into the heater, and heated up. After heating, the fiber is removed from the heater, and the spliced fiber is put into the fiber optic splicing tray. The fiber is fixed to the tray, splice box, terminal box, etc. Finally, the operation is complete.

By utilizing the Optic Fiber Heat Shrink Tube during the fusion splicing process, the integrity and reliability of fiber optic connections are enhanced, ensuring optimal performance in communication networks.