ADSS fiber optic cable

ADSS fiber optic cable has an all dielectric construction that is substantially lighter than traditional aerial fiber cables.

As a professional ADSS fiber optic cable manufacturer & supplier, we specialize in designing, manufacturing ADSS All Dielectric Self Supporting Cable, and providing customized services for our customers!

- PE/AT sheath

- Central tube structure and stranded structure

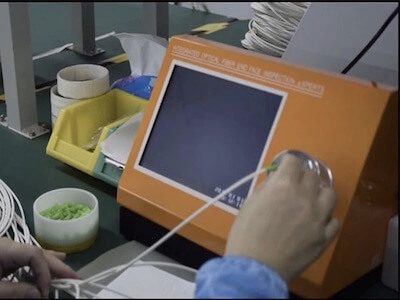

- 100% test before delivery

- Competitive price

- Supply OEM service

- Outdoor aerial application, long-distance telecom, OSP (outside plant) deployment, last-one-mile in the FTTH network.

All Dielectric Self-supporting ADSS Fiber Optic Cable

A type of fiber optic cable that is strong enough to support itself between structures without containing conductive metal elements.

ADSS fiber optic cable, which stands for “all-dielectric self-supporting optical cable,” uses special materials and a built-in support system. This ADSS fiber meaning refers to its ability to function without metallic elements and to support itself.

It offers rapid and cost-effective transmission for power communication systems due to insulation, high temperature resistance, and tensile strength. This cable is installed overhead with ease, making it ideal for existing power lines. It minimizes deployment costs in FTTH networks and enhances fiber accessibility. Its versatility has made it widely adopted in overhead power line systems.

ADSS Aerial Fiber Optic Cable At Bonelinks

ADSS cable is designed for outdoor plant aerial and duct applications within local and campus network loop architectures, spanning from pole-to-building to town-to-town installations. This cabling system, comprising cables, suspension, dead-end, and termination enclosures, provides a comprehensive transmission circuit infrastructure, ensuring high reliability performance.

There are two types of sheaths for ADSS cable. When the line voltage is lower than 110KV, choose PE sheath. When the line voltage is higher than 110KV, choose AT sheath.

There are two structures of ADSS (All Dielectric Self Supporting) fiber optic cables. In the case of small span, ADSS All Dielectric Self Supporting Cable with uni-tube structure can be used. In the case of medium and large span, stranded structure ADSS All Dielectric Self Supporting Cable can be selected. Of course, the corresponding terrain should also be considered at the same time. Leveraging single mode fibers and light wavelengths at 1310 nm or 1550 nm, circuits up to 100 km without repeaters are feasible. Typically, ADSS was utilized in 48 and 96 cores.

If you need further suggestions on choosing the right ADSS Cable, feel free to reach our experienced consultants.

ADSS Fiber Optic Cable 96 Core

96 Core ADSS Aerial Fiber Optic Cable PE Sheath Singlemode

ADSS Fiber Optic Cable 24 Core

ADSS Optical Fiber Aerial Cable 24-Core PE FTTH Singlemode

ADSS Fiber Optic Cable 48 Core

ADSS Aerial Fiber Optic Cable 48 Core PE Single Mode

ADSS Fiber Optic Cable Long Span

Stranded Long Span Distribution Lines AT Sheath Sinlemode Multimode

ADSS Fiber Optic Cable Mini Span

Mini Span Distribution Lines ADSS Aerial Cable Sinlemode Multimode

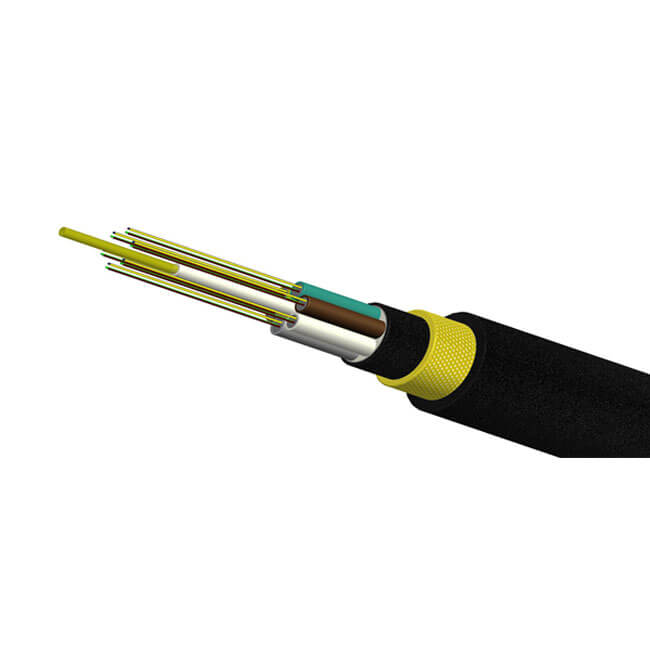

ADSS Cable Stranded Structure

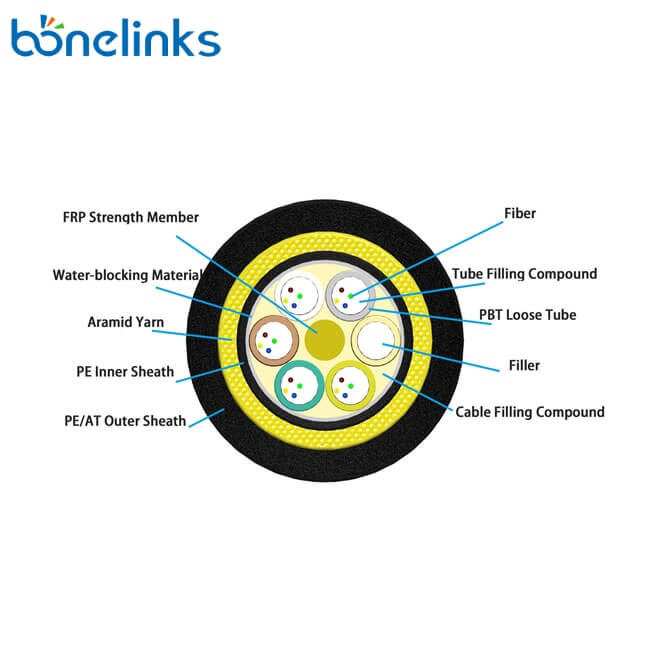

Utilizing a stranded structure design, optical fibers and water-blocking grease are enclosed in loose tubes, wound around a central reinforcement (usually FRP). This type is able to obtain longer fiber lengths.

ADSS Cable Central Tube Structure

In a central tube design, fibers in a PBT loose tube with water-blocking material are wrapped in aramid yarn for desired tensile strength. The structure has small diameter and lightweight but with limited lengths.

Customized ADSS Aerial Fiber Optic Cable

for Your Peace of Mind

We go beyond your expectation. Want to make customized ADSS fiber optic cable? With flexibility and expertise being at the core of our comprehensive product customization service, we have a set of processes and services to meet your special requirements. Based on your need and our extensive experience. You name it, we make it!

Customized Materials & Specifications

for ADSS Fiber Optic Cable

As one of the most professional ADSS All Dielectric Self Supporting Cable suppliers and manufacturers, no matter what specification of fiber optic cables you want, You Can Choose Freely For Your Unique Request.

- 1-24 core, up to 288 core

- Single mode, Multimode

- OS1, OS2,OM2, OM3, OM4…

- G.652D;G.657.A1; G.657.A2 or other Customized Fiber Type

- PVC, LSZH, Flame retardant…

- Unitube, MLT…

- Tensile, Crush, Span…

- 1km, 2km, 4km…

- Marks & Packing…

ADSS Cables Features and Benefits

ADSS cable offers a remarkable advantage in aerial deployments, providing a reliable solution. Their small size, light weight, and strong structure reduce tower loads, ensuring versatility and cost effectiveness in various outdoor applications.

ADSS cables offer an optimal solution, catering to a broader combination of fiber counts and span lengths, making them preferable for telecommunications, power utilities, and private network groups. Their cost-effectiveness enhances aerial fiber-optic deployments for improved performance.

Optimal Solution for Aerial Deployments

ADSS cables offer an efficient and optimal solution for aerial deployments, minimizing cable weight and enhancing support tower reliability. Suitable for various outdoor applications.

Tower Structures and Solar Resilience

The small, light ADSS cable design mitigates external factors, protecting tower structures and preventing moisture and solar ultraviolet light effects.

Moisture Resistance and Structure Strength

ADSS cable design prevents moisture, chemical attacks, ensuring structural strength and protecting polymer strength elements, facilitating installations up to 700m between support towers.

Cost-Effective Distribution Solutions

ADSS cables, an economic alternative to OPGW and OPAC, offer cost-effective solutions for distribution, leveraging existing high voltage power lines. Do not need support or messenger wires, a single pass is sufficient.

ADSS Fiber Optic Cable Price

ADSS Fiber Optic Cable Specifications

| ADSS Aerial Fiber Optic Cable Single Sheath Span 80m to 150m All Dielectric Self-supporting | |||||||

| Item | Contents | Fibers | |||||

| Fiber Count | 6| 12 | 24 | 48 | 72 | 96 | 144 | 288 | |

| Loose Tube | Tubes* Fbres/Tube | 1×6 | 2×6 | 4×6 | 6×8| 4×12 | 6×12 | 8×12 | 12×12 | 24×12 |

| Outer diameter(mm) | 1.8 | 2 | 2.5 | 2.5 | 2.5 | 2.5 | |

| AdustabIe(OEM) | 1.5 | 2.0 | 1.8 | 2.3 | 2.1 | 2.3 | 2.1 | 2.3 | 2.1 | 2.3 | 2.1 | 2.3 | |

| Central strength member | Material | Glass Fbre Reinforced Plasticrod {GFRP) | |||||

| Diameter (mm) | 2 | 2 | 2.5 | 2.8 | 3.7 | 2.6 | |

| Adjustable (OEM) | 1.8 | 2.3 | 1.8 | 2.3 | 2.5 | 2.8 | 3.7 | 2.6 | |

| PE coated diameter (mm) | No | 4.2 | 7.4 | 4.8 | |||

| Water Blocking | Material | Water blocking tape | |||||

| Peripheral Strength | Material | Aramid Yarn | |||||

| Outer Sheath | Thickness (mm) | 1.8mm(1.5-2.0 mm OEM) | |||||

| Cable diameter(mm} Approx. | 9.5 | 9.5|10 | 12.2 | 13.9 | 17.1 | 20.2 | |

| Cable diameter(mm} Adjustable (OEM} | 8.0|8.5|9.0 | 10.5|11.0 | |||||

| Operating temperature range ( ºC) | From -40-+70 | ||||||

| Max. span (m) | 50m | 80m | 100m | 190m | 150m | ||||||

| Climate condition | No lce, 25m/s Max Wind Speed | ||||||

| MAT | Design according to customer requirements | ||||||

| ADSS Aerial Fiber Optic Cable Double Sheath Span 200m to 400m All Dielectric Self-supporting | |||||||

| Item | Contents | Fibers | |||||

| Fiber Count | 6|12 | 24 | 48 | 72 | 96 | 144 | |

| Loose Tube | Tubes* Fbres/Tube | 1×6 | 2×6 | 4×6 | 6x 8 | 4×12 | 6×12 | 8×12 | 12×12 |

| Outer diameter(mm) | 1.8 | 1.8 | 2 | 2.5 | 2.5 | 2.5 | |

| AdustabIe(OEM) | 1.5 | 2.0 | 1.5 | 2.0 | 1.8 | 2.3 | 2.1 | 2.3 | 2.1 | 2.3 | 2.1 | 2.3 | |

| Central strength member | Material | Glass Fbre Reinforced Plasticrod {GFRP) | |||||

| Diameter (mm) | 2 | 2 | 2 | 2.5 | 2.8 | 3.7 | |

| Adjustable (OEM) | 1.8 | 2.3 | 1.8 | 2.3 | 1.8 | 2.3 | 2.5 | 2.8 | 3.7 | |

| PE coated diameter | No | 4.2 | 7.4 | ||||

| Water Blocking | Material | Water blocking tape | |||||

| Peripheral Strength | Material | Aramid Yarn | |||||

| lnnter Sheath | Thickness (mm) | 1.0mm | |||||

| Outer Sheath | Thickness (mm) | 1.8mm(1.5-2.0mm OEM) | |||||

| Cable diameter(mm} Approx. | 12.6 | 12.6 | 13.2 | 14 | 15.3 | 18 | |

| Cable diameter(mm} Adjustable (OEM} | |||||||

| Operating temperature range ( ºC) | From -40-+70 | ||||||

| Max. span (m) | 150m | 900m | 950m | 300m | 400m | ||||||

| Climate condition | No lce,25m/s Max Wind Speed | ||||||

| MAT | Design according to customer requirements | ||||||

Remark:

- Other structure and fibre count are also available according to customer requirements.

- Cable diameter and weight in this table is typical value, which will fluctuate according to different designs.

- The span needs to be recalculated due to other climate conditions according to the installation area.

Applications for ADSS Fiber Optic Cable

Ideal for installation in distribution as well as transmission environments

ADSS all-dielectric self-supporting optical cable is suitable for aerial installations across valleys, lightning-prone areas and other special harsh environments. It is widely used for different (outside plant) deployments.

ADSS cable can be used for applications ranging from short span (40-50 meter) distribution lines to long-span transmission lines (300-500 meter spans) to extraordinary spans required by some river canyon crossings exceeding 1,800 meters. It’s employed in short span aerial installations, commonly on roadside power distribution poles.

Since it is a non-metallic optical cable, ADSS cable can be directly suspended on the overhead power pole and tower. It can be widely used on 220KV, 110KV, and 35KV voltage transmission lines, especially on established lines. It is a direct use of high voltage lines for the power sector.

High-voltage power lines

lightning prone area

Long-span aerial installation

Your Trusted ADSS Fiber Optic Cable Manufacturers

Don’t settle for one ADSS All Dielectric Self Supporting Cable. Choose experienced 10+ years ADSS aerial fiber optic cable suppliers and manufacturers to strengthen your brand. Boost your fiber optic business with Bonelinks Chinese ADSS fiber optic cable.

Competitive price

For bulk purchases, we offer competitive prices to help you save on shipping and purchasing costs.

Low MOQ

For retailers, we accept low minimum order quantities (MOQ) with a minimum of 1 km for optical fiber cable.

reliable product quality

Quality is of utmost importance to us, and we use the advanced manufacturing equipment to produce every product to ensure long-term usage.

Fast delivery

Quick lead time and High production capacity, makes sure the most reliable Chinese ADSS aerial fiber optic cable supply.

Experience In The Industry

With over 10+ years of experience in the fiber optic cable industry, we have the knowledge and expertise to meet the flexible requirements of your fiber cabling system.

Quick response

Our 24-hour online customer service is always available to respond to your inquiries, and our professional sales consultants and high quality technical team are ready to assist you.

FAQs About ADSS Fiber Optic Cables

The minimum order quantity of fiber optic cable is 1km. Because the outside diameter needs to be adjusted before producing.

This process will waste dozens of meters of raw material.

Yes. As long as we confirm the Pantone color code, we can produce the sheath color you request.

Yes. We have Fujikura, Corning SMF 28e, and other brands fiber to choose from.

Yes. We will have a dedicated process engineer to interface with you to understand the specific situation and give our production advice.

Yes. We can print company information or logos on fiber optic cables upon request.

Under 100 km, it takes 4-5 days to produce. under 500 km, it takes 7-10 days to produce.

All fiber optic cables will come with a test report. If you encounter any quality problems, we replace them with new ones free of charge.

We have a special laboratory for high temperature, salt spray and vibration testing.

To calculate sag and tension for ADSS All Dielectric Self Supporting fiber optic cable:

- Use manufacturer-provided sag tension tables.

- Select the table that matches your installation conditions.

- Determine the representative span for your specific application.

- Find sag and tension data corresponding to the representative span.

- Account for compound sag, considering horizontal and vertical components and wind deflection angles.

- Ensure that the ADSS cable’s sag is greater than the overhead wire for safety.

- Choose suitable observation methods for tension measurement.

For example, if the representative span is less than 100m, the overhead wire sag is typically 0.5m, and between 100m and 120m, it’s 0.7m. Construction and daily maintenance experience is vital for the effective application of ADSS optical cables.

The stationary reel method is the most common approach used for ADSS cable installation.

The stationary reel method for ADSS fiber optic cable installation involves using a pre-installed pulling rope for installation. It includes framing the poles, installing pole line hardware, setting up stringing blocks, and installing the pulling rope.

Turnkey ADSS Fiber Solution

In addition to ADSS All Dielectric Self Supporting fiber optic cable, there are also other related ADSS fiber optic accessories available for your convenience.

ADSS Fiber Optic Cable Hardware

Fiber Suspension Clamp

ADSS Cable Fittings & Accessories

Fiber Suspension Clamp is an excellent option for installing ADSS (All Dielectric Self-Support) aerial fiber optic cables near energized zones on utility poles. This clamp is specifically designed for float mounting and is ideally used with a closed eye nut.

ADSS Fiber Optic Cable Hardware

Fiber Shrink Tube

ADSS Cable Fittings & Accessories

Fiber shrink tube is designed to protect and secure optical fibers, providing a durable and reliable layer that can withstand the harsh environments commonly encountered in telecommunications installations.

ADSS Fiber Optic Cable Hardware

Fiber Optic Splice Closure

ADSS Cable Fittings & Accessories

Horizontal fiber optic splice enclosures are known for their rapid and dependable sealing capabilities, making them ideal for a range of applications, including duct installation, direct burial, and ADSS aerial fiber optic cable setups.

A Supplier Provides Products,

But We Care About Your Business.

If you do not find a product that can meet your requirements, please contact us as we might have a solution available.