Quality Management

High Quality Control-We Are Working On It

The ability to produce 25-year quality assurance cables is not the ultimate goal for bonelinks, but rather the starting point for our paranoia about strict quality control. The service life of a fiber optic cable is greatly influenced by the environment in which it is laid, but the structure, component materials and production process are all important factors in giving the cable a strong life, and Bonelinks understands this.

It is well known that fiber optic cables are able to serve as a communication medium because of the refraction of the optical signal inside the fiber. By adding a protective layer to the optical fiber to enable it to transmit signals stably in unused environments, the fiber optic cable is empowering the fiber. To ensure that the optical signal can be transmitted quickly in various complex environments, Bonelinks strictly controls and tests the attenuation of the fiber during the production steps, and designs and adds the necessary structural elements to the overall structure of the fiber optic cable, so that the fiber optic cable maintains stable mechanical properties during the deployment process.

High Quality Control-we are working on it

1

Routinely Prepare

We routinely prepare fiber and aramid yarns for functional testing before stocking.

2

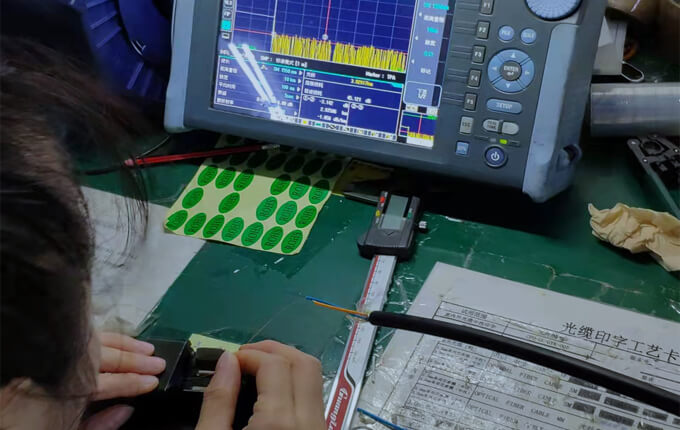

Fusion Distinction

Fiber optic in the coloring to do fusion distinction after the arrangement of the test.

2

Fusion Distinction

Fiber optic in the coloring to do fusion distinction after the arrangement of the test.

3

Fibers Test

Fibers in losse tube will be tested for attanuatoin

4

Mechanical Properties Test

After the fiber is formed, the mechanical properties such as attenuation value and tensile strength will be tested.

4

Mechanical Properties Test

After the fiber is formed, the mechanical properties such as attenuation value and tensile strength will be tested.

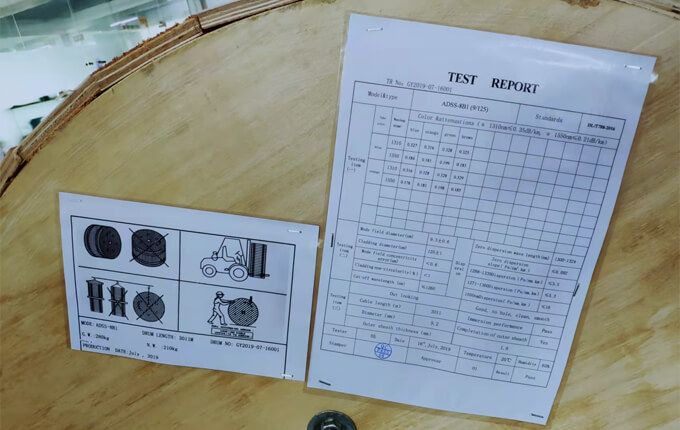

5

Test Report

The fiber optic cable will be shipped with a test report for quality assurance.