Fiber Splitter

As a professional fiber splitter manufacturer, we specialize in design and production, as well as providing fiber splitter to our customers.

- Whole series of 1xN and 2xN fiber splitter

- All products meet GR-1209-CORE and GR-1221-CORE requirements

- Single mode and multimode available

- Wide wavelength range

- Competitive price

- OEM Service can be provided

Best Selling Fiber Splitter

Integrated Waveguide Splitter Device with Multiple Input and Output Ends for Distributing Optical Power

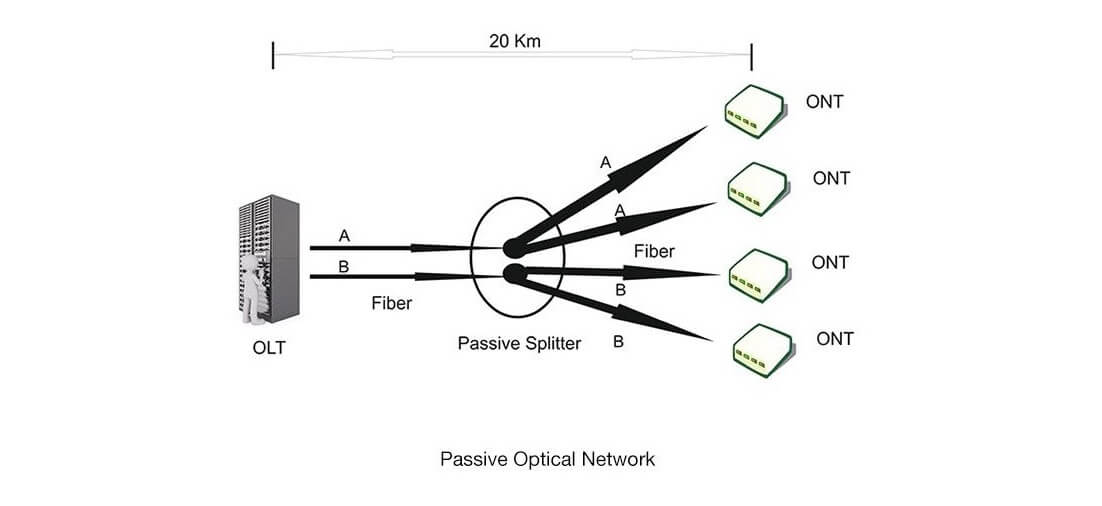

The fiber splitter is a crucial passive management device in optical fiber links, capable of distributing one or two input optical signal into two or more output signal. It is ideal for connecting central office equipment and terminal equipment in FTTX, EPON, GPON, and other passive optical networks.

1×32 FTTH ABS Box Fiber Splitter

1×32 PLC Splitter ABS Module, SC/APC, Singlemode, 1 Input And 32 Output Fibers

1×16 Blockless Mini Fiber Splitter

1×16 Mini Steel PLC Splitter, Singlemode, SC/APC Connector, 1 Input And 16 Output Fibers

1×2 Blockless Mini FTTH Fiber Splitter

1×2 Mini Steel PLC Splitter, Singlemode, SC/APC Connector, 1 Input And 2 Output Fibers

1×4 FTTH Blockless Fiber Splitter

1×4 Mini Steel PLC Splitter, Singlemode, SC/APC Connector, 1 Input And 4 Output Fibers

1×16 ABS Box FTTH Fiber Splitter

1×16 PLC Splitter, ABS Module, SC/APC, Singlemode, 1 Input And 16 Output Fibers

1×64 ABS Box FTTH Fiber Splitter

1×64 PLC Splitter, ABS Module, SC/APC, Singlemode, 1 Input And 64 Output Fibers

1×16 Cassette type FTTH Fiber Splitter

1×16 PLC Splitter, Plug-In Type,Uniform Signal Distribution, 1 Input And 16 Output Fibers

1×16 Rack Mount ODF FTTH Fiber Splitter

1×16 PLC Splitter, 1U 19″ Rack Mount, SC/APC, Singlemode, 1 Input And 16 Output Fibers

1×4 LGX type FTTH Fiber Splitter

1×4 PLC Splitter, Standard LGX Cassette, SC/APC, Singlemode, 1 Input And 4 Output Fibers

1×8 Cassette FTTH Fiber Splitter

1×8 PLC Splitter, Plug-In Type,Uniform Signal Distribution, 1 Input And 8 Output Fibers

1×32 Cassette FTTH Fiber Splitter

1×32 PLC Splitter, Plug-In Type,Uniform Signal Distribution, 1 Input And 32 Output Fibers

1×2 ABS Box LC FTTH Fiber Splitter

1×2 PLC Splitter, ABS Module, SC/APC, Singlemode, 1 Input And 2 Output Fibers

Fiber Splitter Price and New Catalogue

Explore Versatile Configuration Options for Fiber Splitter

Passive optical splitters can split, or separate, an incident light beam into several light beams at a certain splitting ratio.

Experience seamless signal distribution with our optical fiber splitter, available in various configurations. Choose from 1×2 fiber splitter, 1×4 fiber splitter, 1×8 fiber splitter,1×16 fiber splitter,1×32 fiber splitter and 1×64 fiber splitter. Enhance your network infrastructure with our versatile and reliable fiber splitter for efficient data transmission.

Fiber Splitter 1×2

1x2 PLC Splitter, SC/APC or No Connector, Singlemode, 1 Input And 2 Output Fibers

Fiber Splitter 1×4

1x4 PLC Splitter, SC/APC or No Connector, Singlemode, 1 Input And 4 Output Fibers

Fiber Splitter 1×8

1x8 PLC Splitter, SC/APC or No Connector, Singlemode, 1 Input And 8 Output Fibers

Fiber Splitter 1×16

1x16 PLC Splitter, SC/APC, LC/APC or No Connector, Singlemode, 1 Input And 16 Output Fibers

Fiber Splitter 1×32

1x32 PLC Splitter, SC/APC or No Connector, Singlemode, 1 Input And 32 Output Fibers

Fiber Splitter 1×64

1x64 PLC Splitter, SC/APC, LC/APC or No Connector, Singlemode, 1 Input And 32 Output Fibers

1×3 and 1×5 Configurations for Optimized Applications

Expanding Possibilities for Fiber Splitting

Our product offerings include a range of splitting ratios for different applications. In the market, the general splitting ratios available are 1 × 2/4/8/32/64/128. However, Boenlinks has conducted extensive research in the field and has developed innovative solutions, specifically for smart home and FTTR applications.

● 1 × 3/6/12/24 splitting

We offer 1 × 3/6/12/24 splitting. These products have undergone the same production process as the common and special PLC splitters, and they are designed to operate at the detection wavelengths of 1310/1490/1550 nm.

● 1 × 5/7/9/17 splitting

We provide 1 × 5/7/9/17 splitting. These products utilize an output fiber for cascaded connections to an ordinary PLC splitter. They are optimized for the detection wavelengths of 1310/1490/1550/1625/1650 nm.

Contact us for more information.

Explore Versatile Packaging Options for Fiber Splitter

The optical splitter, terminated with various connectors, comes in box or stainless tube types. Fiber splitter box is usually used with 2mm or 3mm outer diameter cable, while the others is normally used in combination with 0.9mm outer diameter cable.

Experience seamless signal distribution with our optical fiber splitter, available in various packaging methods. Choose from Steel Tube/Mini Module fiber splitter, Plugin fiber splitter, ABS Module fiber splitter, LGX Metal Box fiber splitter and Rack Mount fiber splitter. Enhance your network infrastructure with our versatile and reliable fiber splitter for efficient data transmission.

ABS Box Fiber Splitter

ABS Box PLC Splitters Pre-terminated with FC, SC, LC, ST Connectors Cassette Module, Split Input Signal Evenly Across All Output Fibers

Bare Fiber Splitter

Bare Fiber Type PLC Splitters without Connector 1×2 1×4 1×8 1×16 1×32 Single Mode, Split Input Signal Evenly Across All Output Fibers

Blockless Steel Tube Fiber Splitter

Blockless PLC Splitters Mini type Steel Tube Pre-terminated with FC, LC and ST, SCUPC and SCAPC, Split Input Signal Evenly Across All Output Fibers

LGX Fiber Splitter

LGX PLC Splitters 19-inch 1U/2U/3U Cabinet Plug and Play Metal Box Module SC, FC, LC Connector, Split Input Signal Evenly Across All Output Fibers

Plug-In Fiber Splitter

Plug-In Box Module PLC Splitters Pre-terminated with SC, LC Connectors G657A Card Type, Split Input Signal Evenly Across All Output Fibers

Rack Mount Fiber Splitter

Rack Mount PLC Splitters Standard 19″ Cabinet 1U Rack Design 1×8 1×16 1×32 SC LC FC Connector G657A, Split Input Signal Evenly Across All Output Fibers

We Supply Both PLC Splitter and FBT Splitter

FBT and PLC are the two main choices for the majority of users. FBT splitters are based on traditional technology to weld several fibers together from the side of the fiber, PLC splitters are based on planar lightwave circuit technology. Both FBT and PLC fiber optic splitters are available at Bonelinks.

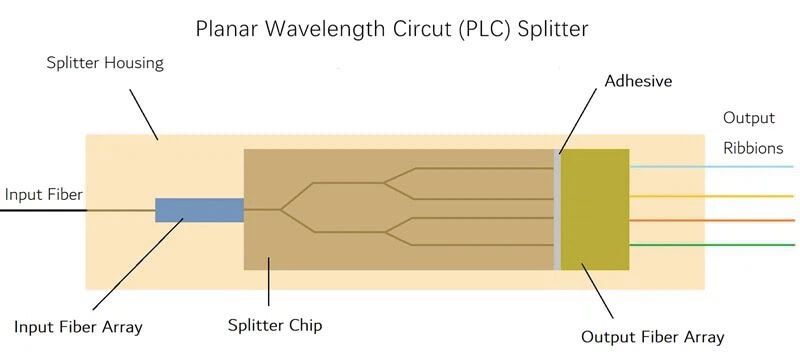

Planar Lightwave Circuit

PLC Splitters

PLC Splitters are single mode fiber splitters with an even split ratio from one input fiber to multiple output fibers. In contrast to fused fiber couplers, where light is coupled from one fiber core to the other, these devices operate as a continuous waveguide that splits the propagating signal. PLC optical splitters make it possible for the transmission power at each splitter output port to be the identical, simplifying network architecture and lowering expenses.

Fused Biconical Taper

FBT Splitters

FBT splitter is where the optical splitting of the signal is achieved by fusing two fibers into one or four fibers into one under high temperatures. It features lower costs and is regarded as a cost-effective solution.

Fiber Optic PLC Splitters:

Important Passive Devices In PON Networks

Unlock seamless data distribution with our cutting-edge fiber optic PLC splitters. PLC splitter is based on PLC (Planar Lightwave Circuit) technology and is suitable for high density applications. These important passive devices boast low insertion loss, thanks to their advanced quartz substrate and precision PLC splitter chip. Revolutionize your PON networks with their efficient compact structure and stay at the forefront of optical fiber technology.

Optical Splitters: Empowering Passive Optical Networks with Shared PON Interfaces

By allowing a single PON Interface to be shared by multiple subscribers, optical splitters have played an essential role in passive optical networks. The optical splitters divide the fiber optic light into numerous sections at a specific ratio.

PLC Splitters Key Features

Help users maximize the performance of optical networks circuits.

- Operates across the full wavelength of 1260-1650 nm

- Available in a variety of split ratios and can be divided into several housing types

- Maintains an even split ratio throughout the entire bandwidth

- Compact and space-saving design

- Low polarization dependent loss (PDL) and temperature sensitivity

- Provides high directivity

- Standard operating temperature range of -40°C to +85°C

- Fully tested and compliant with Telcordia® 1209 and 1221 criteria

PLC Splitters Applications

Integral component and widely used in most optical networks.

- Ideal for FTTX deployment

- Suitable for Fiber to the Home (FTTH) networks

- Compatible with Passive Optical Networks (PON)

- Supports Local Area Networks (LAN)

- Enables Cable Television (CATV) connections

- Suitable for use with test equipment

- Facilitates optical signal distribution

- Supports data communications

- Compatible with measuring systems and laser systems

- Compatible with DWDM and CWDM systems

PLC Optical Splitters Specifications

| Item | Unit | Parameter | |||||||||||||

| PLC Splitter Confuguration | -- | 1×2 | 1×4 | 1×8 | 1×16 | 1×32 | 1×64 | 1×128 | 2×2 | 2×4 | 2×8 | 2×16 | 2×32 | 2×64 | |

| Operating Wavelength | (nm) | 1260 ~ 1650 | |||||||||||||

| Insertion Loss | MAX(P/S) | (dB) | 3.8/4.0 | 7.0/7.4 | 10.5/10.7 | 13.6/13.9 | 16.6/16.9 | 21/21.5 | 24/24.5 | 4.0/4.3 | 7.4/7.6 | 10.7/11.0 | 14/14.5 | 17.5/18 | 21.4/21.9 |

| Uniformity | MAX(P/S) | (dB) | 0.6/0.6 | 0.6/0.7 | 0.8/1.0 | 0.9/1.2 | 1.2/1.4 | 1.7/1.9 | 2.2/2.5 | 0.9/1.1 | 1.0/1.2 | 1.0/1.2 | 1.2/1.5 | 1.5/1.8 | 2.0/2.3 |

| Return Loss | MIN | (dB) | 55 | ||||||||||||

| PDL | MAX(P/S) | (dB) | 0.15/0.25 | 0.15/0.25 | 0.2/0.25 | 0.2/0.3 | 0.25/0.3 | 0.25/0.35 | 0.4/0.45 | 0.25/0.3 | 0.25/0.3 | 0.25/0.3 | 0.3/0.35 | 0.3/0.35 | 0.35/0.4 |

| Fiber Type | -- | ITU-T G657A1 , G657A2 | |||||||||||||

| Temperature Stability(-40~85℃) | MAX(℃) | (dB) | 0.5( Typical 0.3 ) | ||||||||||||

| Operating Temperature | (℃) | -40 ~ 85 | |||||||||||||

| Storage Temperature | (℃) | -40 ~ 85 | |||||||||||||

Fiber Splitter For Wholesale

FTTH PLC splitter manufacturer

As a trustworthy fiber optic splitter supplier, Bonelinks offers cost-effective and excellent fiber optical splitter with a wide range of options. You can choose freely for your unique fiber optic request.

- Standard and custom fiber optic splitters

- 1:8, 1:16, 1:32, 1:64, 2:8, 2:16, 2:32 and 2:64 splitting ratio.

- SC, LC, FC, or ST connectors or no connectors

- Bulk bare fiber splitters, blockless fiber splitters, ABS fiber splitters, rack-mount fiber splitters, LGX fiber splitters, and plug-in fiber splitters.

- PLC splitter, FBT splitter.

While most fiber splitter manufacturers provide products, Bonelinks takes your business to the next level. Our customer satisfaction rate of 95% and a 30% increase in operational efficiency attest to our commitment. Experience superior service, tailored solutions, and a 24/7 support team with Bonelinks. Your success is our priority.

Customized Fiber Optic Splitter

for Your Peace of Mind

Our goal is to fulfill your unique optical splitter needs through our complete range of personalized product services. We’re flexible and skilled in designing custom fiber splitter that match what you need, drawing from both your requirements and our deep experience in the field.

Customized Materials & Specifications

for Fiber Splitter

At Bonelinks, you have the freedom to choose the materials and specifications for your unique fiber optical splitter requirements.

- Input: 1; 2

- Output: 2;4;8;16;32;64;128; etc

- Fiber Type: G.652D;G.657.A1; G.657.A2 or other Customized Fiber Type

- Diameter: 250μm;0.9mm (with Loose Tube );2.0mm;3.0mm;ect

- Length: 0.5M; 1M; 1.5M, etc

- Input Connector: No Input Connector;LC;SC;FC

- Output Connector:No Output Connector;LC;SC;FC

- Connector Endface:UPC;APC;PC

- Package: Steel Tube/Mini Module; Plugin; ABS Module; LGX Metal Box; Rack Mount, ect

- Splitter Type: FBT; PLC

Your Competent Optical Splitter Manufacturers

Achieving success goes beyond a single fiber optic splitter. Partner with a 10+ years veteran supplier like Bonelinks to build your brand and boost business through collaborative efforts.

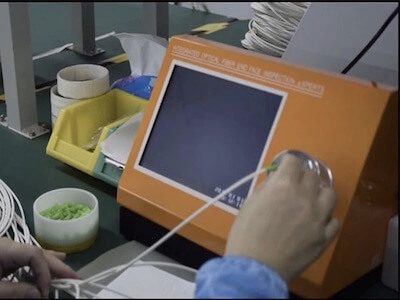

Advanced manufacturing equipments

In our fiber splitter production, we employ advanced manufacturing equipment, encompassing automatic alignment machines, fiber curing devices, cutting and assembly tools, polishing machinery, ferrule glue injection systems, and insertion/return loss testers.

Competitive price

When ordering fiber splitter in large quantities, we present competitive pricing options that enable you to reduce expenses related to shipping and procurement.

Guaranteed quality

Superiority is of the most importance thing to us, and we use the latest networking equipment to test every product to ensure high reliability and long-term usage.

Fast delivery

Quick lead time and high production capacity, makes sure the most reliable fiber splitter supply.

Experience In The Industry

With over 10 years of experience in the production of fiber optic cables, optical splitter, and patch cords, we can accommodate the needs of your fiber optic cabling system.

Quick response

Whether you have questions about fiber splitter or need guidance, our 24/7 online customer service is at your disposal. Additionally, our skilled sales consultants are prepared to lend their expertise whenever you require assistance.

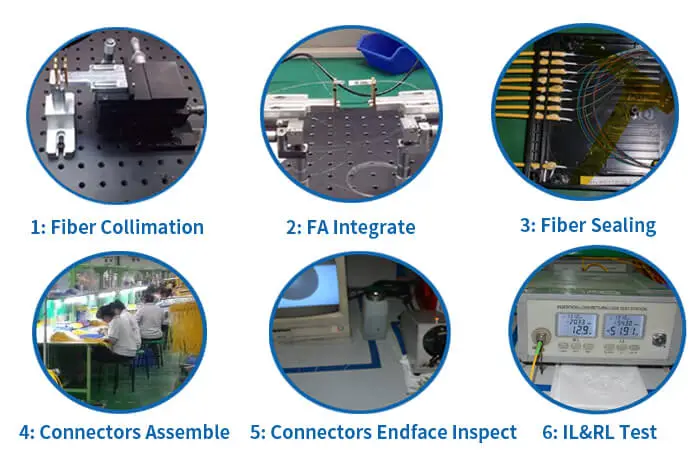

Fiber Splitter Manufacture Process

Manufacturing an optical splitter involves a total of six critical steps. Each step requires strict control and management of various parameters like environment, temperature, and detailed precision on assembly and equipment.

- Fiber Collimation

- FA Integration (Fiber Array Integration)

- Fiber Sealing

- Connector Assembly

- Connector Endface Inspection

- Insertion Loss (IL) and Return Loss (RL) Testing

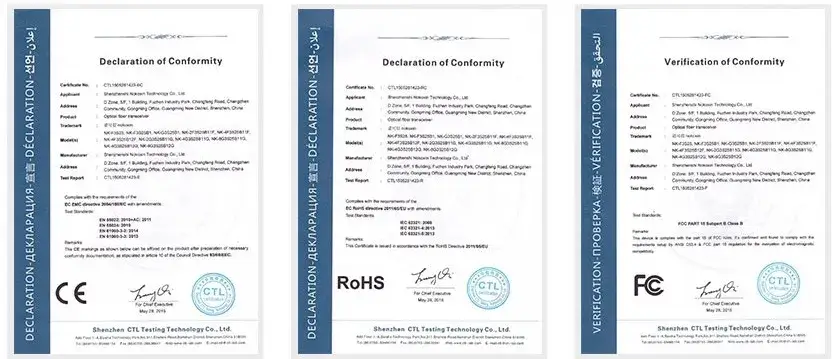

Quality Assurance through Certified Inspections for Fiber Splitters

We prioritize providing top-notch fiber optic splitter that meet the stringent demands of the industry. Our commitment to quality assurance through end face checking, 3D testing, core tuner testing, UV curing, and tensile testing sets us apart, ensuring that our customers receive reliable and efficient fiber optical splitter for their optical network requirements.

IL RL Test

Verified insertion and return loss for seamless signal distribution.

3D test

Ensure flawless signal splitting with our rigorously tested fiber cable splitter.

High-low temperature test

Reliable performance in varying environmental conditions with tested PLC splitters.

Choose Bonelinks for superior fiber splitter services

Superior Services for Diverse Customers

Our premium fiber splitter products, competitive prices, and exceptional service make us ideal fiber optic splitter supplier for all customers.

Wholesale

Get cost-effective, top-notch fiber splitter that exceed industry standards. Collaborate with us for competitive pricing.

E-commerce

We support low purchase requirements with flexible MOQs and fast delivery. Our fiber optic splitter offer excellent quality and competitive prices.

For Contractors, ISPs or Operators

Simplify your project procurement with our all-in-one solution tailored for fiber splitter. Count on us for superior caftsmanship, customizable options, and a streamlined production process that ensures successful project outcomes.

4 Steps to Get Your Fiber Splitter

The process is easy!

Leverage our expertise to design and deliver customized fiber splitter within a swift turnaround. Our efficient production process creates cost-effective and robust fiber optic solutions, meticulously tailored to precisely match your distinct requirements.

1

Specify Your Needs

Speak with our experts to confirm the specifications and custom details of your fiber splitter. This step can be completed in just one hour.

2

Confirm And Make Payment

Once all the details are set, make the advance payment. It usually takes one or two days for the payment to reach our bank account.

3

Production & Inspection

After payment is received, we’ll get started on fiber splitter production and keep you updated. Shipping usually takes 2-3 weeks.

4

Shipping & Delivery

Before shipping, we’ll send you details of the products and packing. All fiber splitter will be delivered to the port on the same day.

You Ask, We Answer

Yes, the price can be negotiated based on the quantity of your order.

When selecting fiber optic splitters, consider crucial factors for optimal performance in your system:

- Insertion Loss: A smaller insertion loss value indicates better splitter performance.

- Return Loss: A higher return loss is generally preferable.

- Splitting Ratio: This defines the output power of the splitter output port in the system, correlated with the wavelength of the transmitted light.

- Isolation: Indicates the optical signal isolation of a light path splitter from other optical paths.

Additionally, consider parameters such as uniformity, directivity, and PDL (polarization loss) for a comprehensive evaluation of optical splitter performance.

A simple plug-in optical splitter is a type of splitter that has no jumper wires and has a direct connection between the ferrule and the adapter. It is different from the conventional type as it does not have a part head or half an adapter.

Of course, we would be happy to help you. Please provide us with more details about your application and we will recommend PLC fiber splitter products that are suitable for your needs.

Yes, we have the ability to offer high-quality OEM/ODM PLC fiber splitter products to our customers. However, there is a minimum order quantity required.

Yes, the box of the splitter can be customized with your company’s logo to enhance brand recognition.

Yes, the fiber optic splitter can be pre-terminated with FC, SC, LC, and ST fiber connectors to meet your specific usage requirements. Please note that we also offer fiber splitters without connectors.

Yes, we can customize the input and output lengths of the fiber splitter to be as short as 0.5m to minimize internal redundancy.

Yes, we can customize the package tubing to be of different sizes to reduce the equipment’s footprint.

For orders under 100 km, it takes 4-5 days to produce. For orders under 500 km, it takes 7-10 days to produce.

All of our fiber optic splitters undergo thorough testing before production. The splitters are tested for through-light, end-face, and split ratio after pre-terminated connectors are installed. Each port is also tested for attenuation values after the product is produced. Test reports are attached to each product for performance confirmation and quality assurance. In the unlikely event of a quality issue, we will replace the product free of charge.

A Supplier Provides Products,

But We Care About Your Business.

If you do not find a product that can meet your requirements, please contact us as we might have a solution available.