Air Blown Fiber Optic Cable

Air blown fiber optic cable breaks through the limitations of the existing duct cable installation technology, can greatly improve the utilization efficiency of the duct hole and is easy to expand. As a professional air blown fiber optic cable manufacturer & supplier, we specialize in designing, manufacturing air blown fiber optic cable, and providing customized services for our customers!

- Indoor and outdoor application

- Competitive price

- OEM service can be provided

- 100% quality assurance

Air Blown Fiber Systems and Solutions

Easy to strain, sprain, and scratch the optical cables when laying? How to improve the utilization efficiency of existing pipe holes? How to save labor and construction costs? How to improve installation efficiency? Air-blown optical cable came into being.

Air blown fiber optic cable (ABF), also known as air blown micro cable, is a fiber cable that can be installed in tiny ducts without excavation by air-blown installation technology. It is known for its small outside diameter and high core capacity, and is designed to be used in backbone networks, metro networks and access networks to meet the demand for high speed bandwidth while reducing the cost of ducting infrastructure construction and lowering the purchase cost of fiber optic cable lines. It is an advanced solution for FTTx network, it effectively saves costs for splicing joint and distribution management.

Air Blown Fiber Optic Cable Types At Bonelinks

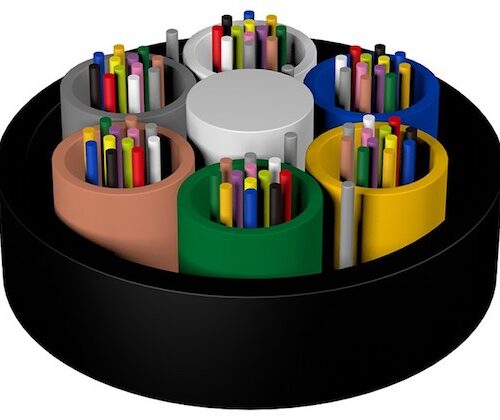

Air blown fiber optic cable is divided into two types: unitube air blown fiber optic cable and stranded air blown fiber optic cable. The unitube air blown fiber optic cable has a small count cores(6-48 cores) and small diameter. The air-blown micro-optical cable with a large count cores(6-144 cores) adopts an all-dielectric loose-tube stranded structure.

Air Blown Micro Cable Unitube

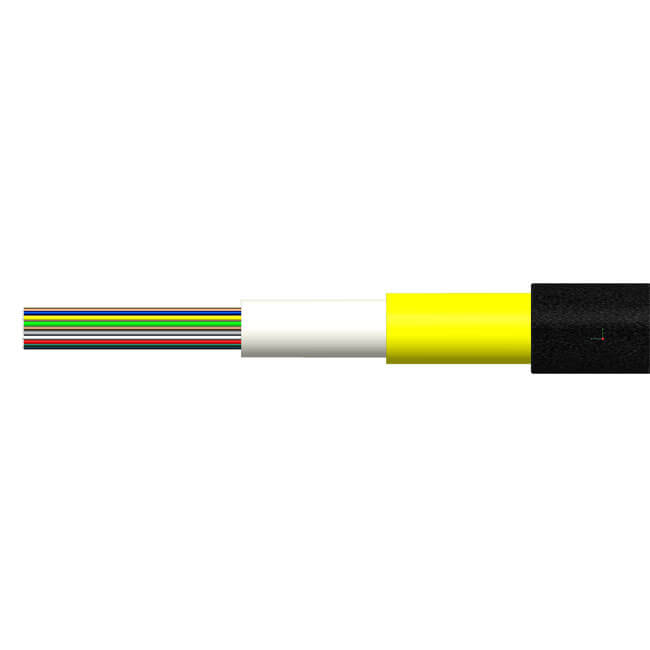

Air blown micro cable is ultra-lightweight in small diameter to be blown into a micro duct. Fiber bundles of this cable is formed by curing optical fiber or fillers into photosensitive resin in a certain arrangement. And outside extruding a special low friction sheath. It is designed for metro feeders or access networks. The micro cable provides a lower initial investment and the flexibility to install and upgrade to the latest fiber technologies.

- Perfect cable structure with high fiber density

- Small diameter and lightweight

- HDPE sheath, enhancing the blowing performance

- Allowing to blow out and replace with new cables to keep technical superiority

- Allowing to cut micro ducts anywhere anytime for branches without influences on other cables, saving manholes, hand holes, and cable joints

Blown Fiber Optic Cable Stranded Micro Cable

GCYFY blown fiber optic cable is suitable to be installed in crowded metropolitan area network pipelines. It performs well in improving the utilization ratio of pipe holes and avoiding destructive excavation in the past. It is designed with loose tube construction. The tube is filled with a water-resistant filling compound. A fibre reinforce plastic locates in the center of the core as a non-metallic strength member. The tubes (and the fillers) are stranded around the strength member into a compact and circular core. The cable is completed with a PE sheath.

- Small diameter, lightweight, easy to bend when laying by air-blowing equipment, easy to operate

- All non-metal structures, no need to be grounded, low friction coefficient sheath material and structure design, long-distance air blown laying

- Full use of pipe hole resources, construction speed is fast

- Allowing to blow out and replace with new cables to keep technical superiority

- Avoiding destructive excavations and no need to pay high fees for deploying permission, applicable for constructions in crowded metropolitan area networks

- Allowing to cut micro ducts anywhere anytime for branches without influences on other cables, saving manholes, hand holes, and cable joints

- Loose tube filled with special waterproof compound

- Using dry type of water blocking material, the whole section of water resistance, to prevent the optical cable vertical seepage

Customize Air Blown Fiber Optic Cable

for Your Peace of Mind

We go beyond your expectation. Want to make customized air-blown fiber optic cable? With flexibility and expertise being at the core of our comprehensive product customization service, we have a set of processes and services to meet your special requirements. Based on your need and our extensive experience. You name it, we make it!

Custom Materials & Specifications

For Air Blown Fiber Optic Cable

Bonelinks provides the solutions, whether there is a requirement for high fiber density or a compact cable diameter. Our designs consistently prioritize minimal cable and duct diameters, ensuring a cost-effective installation with high-quality materials.

No matter what specification for air blown fiber optic cable, at Bonelinks, You Can Choose Freely For Your Unique Request.

- 1 – 288 Core

- Single mode, Multimode

- OS1, OS2,OM2, OM3, OM4…

- G.652D;G.657.A1; G.657.A2 or other Customized Fiber Type

- Metallic, All dielectric…

- Unitube, MLT…

- Tensile, Crush, Span…

- 1km, 2km, 4km…

- Armored, Non armored…

Air Blown Fiber Optic Cabling

Install Fiber Optic Cable By Air Pressure

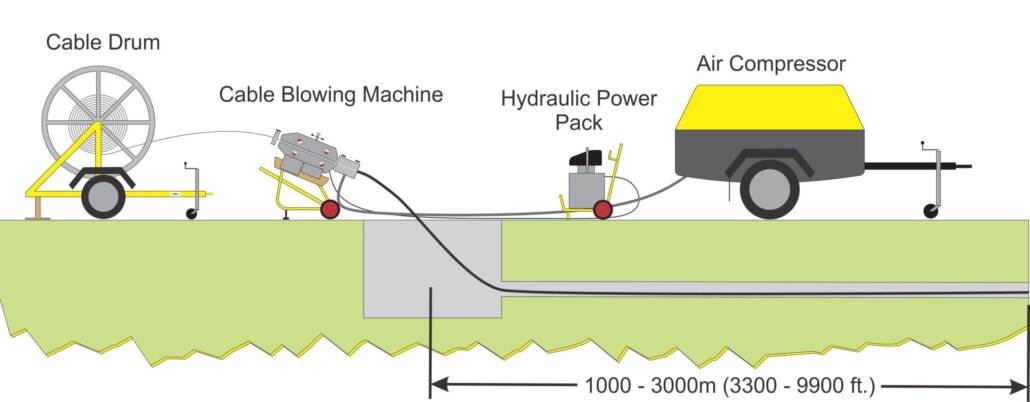

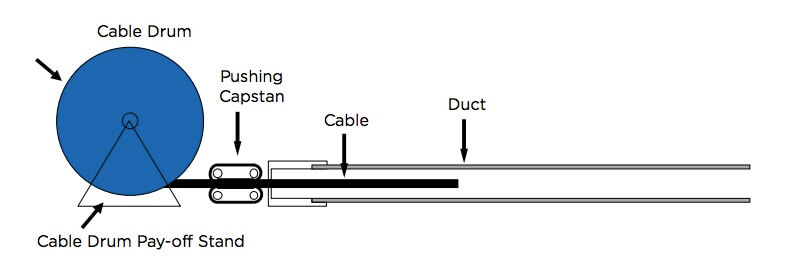

Fiber optic cable blowing is a highly efficient and safe method for installing fiber optic cable. It involves a pressurized blowing system that utilizes both pulling force and pushing force to guide the fiber optic cable through the duct like air, ensuring smooth and reliable installation.

Conduit systems allow for the installation of microducts and cables as needed. This provides installers with the flexibility to deploy fiber only when necessary, leading to a reduction in initial investment costs. Planning for future installations ensures the incorporation of the latest fiber optic technology, thus adapting to evolving market demands.

ABF systems offer the advantages of overriding existing networks and conduits, thereby minimizing network disruption and avoiding costly excavation expenses and permits during installation. The ABF cable, designed with a specially crafted low-friction jacket, is lightweight and flexible, allowing for extended jetting length, ultimately contributing to significant time and cost savings.

Blowing Fiber: Push It Forward.

Blowing fiber, also known as jetting, is when a machine is used to float fiber optic cable through the conduit run by using highly pressurized air to push it forward. While the set-up is more extensive, blowing fiber is great for long distances and can go thousands of feet.

It is an efficient way to install fiber optic cable and facilitates future fiber expansion of optical networks.

Blowing Fiber: Here’s The How-To.

Air Blown Fiber Optic Cable Applications

Space Efficient Solutions for Limited Location

Bonelinks offers a cutting-edge solution with its advanced air blown fiber systems designed for underground duct networks. The comprehensive solutions cater to a variety of applications and requirements, spanning from backbone networks to FTTx.

In the FTTH network, it is used as the feeder section to introduce the optical cable. Air blown fiber optic cable is suitable for application in the backbone network, metropolitan area network and access network, to realize the expansion of the existing communication pipeline, solve the problem of terminal access, and provide reserved pipe holes for future use after expansion. Blown fiber and micro tubes are equally suitable for outdoor use as well as indoor use. For indoor applications, flame retardant micro tubes are used.

FTTH access network

backbone network

metropolitan area network

Features and benefits

Fully Utilized Holes

The optical fiber assembly density is high, and the tube hole resources are fully utilized by laying reusable sub-tubes.

Future Expansion

The fiber optic cable can be blown in batches with the increase of communication business to meet the needs of users in a timely manner. It is convenient to adopt new types of optical fibers in the future and maintain technically.

Low Initial Investment

saving up to 65% to 70% of the initial investment compared with traditional network construction methods.

Reducing Construction Cost

It can be used for newly deployed HDPE main pipes or existing PVC main pipes, and can be connected to new users without affecting the normal operation of optical cables that have been opened.

Save Labor Cost

It is easy to expand in parallel and vertically, reduce the workload of trenching, and save the cost of civil engineering.

High Efficiency

The air blowing speed of the micro cable is fast and the air blowing distance is long, and the laying efficiency of the optical cable is greatly improved.

Enhancing System Performance

Minimizing optical loss through splicing and interconnection points for enhanced system performance

Your Trusted Air Blown Fiber Manufacturers

Innovation, Quality, Service and Responsibility

- Our R&D team, skilled workers, advanced machines, and modern factories can provide our customers with outstanding quality service.

- On the flexibility

- High-quality control standard

- Plenty of Certificates of products and customs

- Professional expert team

- 24/7 Availability

You Ask, We Answer

Cable installation by using high speed air flow combined with additional mechanical pushing force is called as

“blowing or jetting”. Cable blowing is the process of installation of optical fiber cable into a pre-installed duct. Compressed air is injected in the duct inlet after few hundred meters of cable is pushed into the duct. Compressed air flows at high speed through the duct and along the cable.

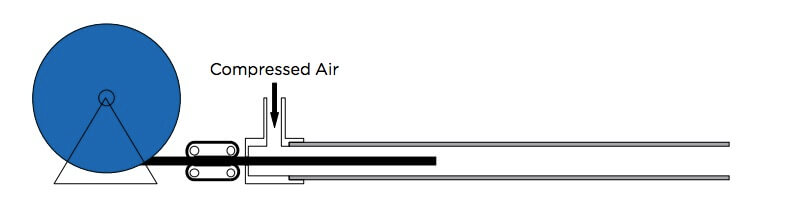

Method 1: High air speed blowing

This method requires pushing the cable with tractor mechanism by traction rollers in blowing device for a few hundred meters and then introducing compressed air to make the cable inside the ducts remain in floating condition, which reduces friction between the cable outer surface and duct inner wall by reducing area of contact.

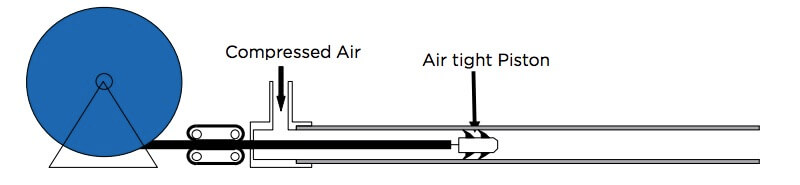

Method 2: Push/Pull (Piston) blowing

In this type of blowing unit, an air-tight piston is attached to the front of the cable. The air pushes this piston, and the piston “pulls” the cable. Installers should be aware that a pulling force exists in piston blowing, and the pulling force shouldn’t cross the maximum cable tension. This method is preferred for larger size ducts (32/40mm and 42/50mm) and in “straight” trajectories to achieve longer cable blowing distance.

The procedure for fiber optic cable blowing typically involves the following steps:

- Prepare the conduit by cleaning it and ensuring that there are no obstructions or damage.

- Attach the cable to the blowing head and lubricate the cable with a gel to reduce friction.

- Insert the blowing head and cable into one end of the conduit.

- Use a blowing machine to introduce pressurized air into the conduit, pushing the cable through the conduit.

- Monitor the progress of the cable as it is blown through the conduit, checking for any issues such as snags or kinks in the cable.

- Once the cable has been blown through the entire length of the conduit, use a pulling eye to pull the cable through the last few feet of conduit to ensure that it is properly seated.

- Perform a continuity test to ensure that the cable is functioning properly.

- Cable blowing is an efficient method for installing cable in long runs of conduit, and it can be used for both new installations and retrofits.

However, it is important to ensure that the conduit is in good condition and that the cable is properly lubricated and attached to the blowing head to avoid damage to the cable during the installation process.

The installation process and hardware differ from the conventional fiber optic cables. This involves tubing for fiber blowing, special coated fiber or bundles that can be blown into the tubes, specialized hardware for termination and splicing, and a blowing apparatus providing the controlled air stream (or dry nitrogen) essential for blowing fibers into the tubes over several kilometers.

Air blown micro fiber optic cable is a fiber optic cable designed for use in air-blown fiber optic systems.

These systems use compressed air to blow small-diameter fiber optic cables through tubes or ducts, allowing them to be quickly and easily installed without requiring specialized equipment or labor-intensive techniques.

Air-blown micro fiber optic cable typically has a small diameter, less than 1 mm, and is made of a flexible material, such as plastic or rubber. This allows it to be easily blown through tubes or ducts and bent around corners or other obstacles.

Air-blown micro fiber optic cable is commonly used in telecommunications and broadband applications.

Yes, connections must be designed to seal effectively, preventing air leaks and maintaining the desired air pressure throughout the fiber deployment process.

The minimum order quantity of cables is 1km. Because the outside diameter needs to be adjusted before producing.

This process will waste dozens of meters of raw material.

Yes. As long as we confirm the Pantone color code, we can produce the sheath color you request.

Yes. We have Fujikura, Corning SMF 28e, and other brands fiber to choose from.

Yes. We will have a dedicated process engineer to interface with you to understand the specific situation and give our production advice.

Yes. We can print company information or logos on cables upon request.

Under 100 km, it takes 4-5 days to produce. under 500 km, it takes 7-10 days to produce.

All cables will come with a test report. If you encounter any quality problems, we replace them with new ones free of charge.

We have a special laboratory for high temperature, salt spray and vibration testing.

Turnkey Air Blown Fiber Systems and Solutions

Hardware For The Air Blown Fiber System

Bonelinks’ air blown fiber product line provides complete solutions tailored to a wide range of applications, from backbone networks to FTTx. Whether you need high fiber density, a smaller cable diameter, or even an air blown fiber installation tool, we have the solution to meet your specific requirements.

Straight Microduct Air Blown Fiber Optical Cable Connector

Straight Microduct Connector

Microduct connector is a kind of connection for air-blown fiber optic cable or air-blown miniature fiber optic cable conduit in backbone network construction, to ensure that the air pressure can be stable through the connection without leakage, so as to complete the smooth passage of fiber optic cable in the connection node of the conduit.

Microduct Fiber Optic Cable

air-blown microduct fiber optic cable

Microduct fiber optic cable is mainly used in air-blown micro cable technology cabling use, fiber optic cable can ride on the direction of the jet airflow in the HDPE microtube at a uniform speed, which not only reduces cabling laying costs but also improves construction efficiency.

A Supplier Provides Products,

But We Care About Your Business.

If you do not find a product that can meet your requirements, please contact us as we might have a solution available.