China Figure 8 Fiber Optic Cable Supplier

Figure 8 fiber optic cable is the optical cable that has a cross-section shape like figure 8. Exquisitely designed, and easy to install. It is suitable for outdoor aerial installation and FTTH network. As a professional figure 8 fiber optic cable manufacturer & supplier, we specialize in designing, manufacturing figure 8 fiber optic cable, and providing customized services for our customers!

- Small size and lightweight

- Flexible and easy to construction

- Competitive price

- OEM Service can be provided

- 100% quality assurance

Figure 8 Fiber Optic Cable

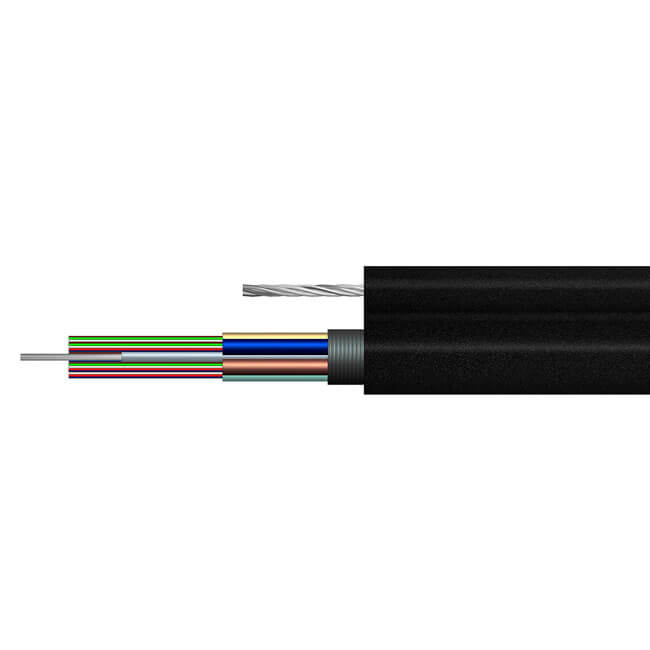

Figure 8 cable integrates the cable core and the steel stranded wire into an 8-shaped PE sheath to form a self-supporting structure. During the laying process, there is no need to erect hanging wires and hooks. The construction efficiency is high and the construction cost is low. The compact, self-supporting figure 8 aerial fiber optical drop cable was developed to interconnect optical equipment indoors and outdoors in FTTH network branches, it is an enhanced performance FTTH solution.

Figure 8 Fiber Optic Cable Products

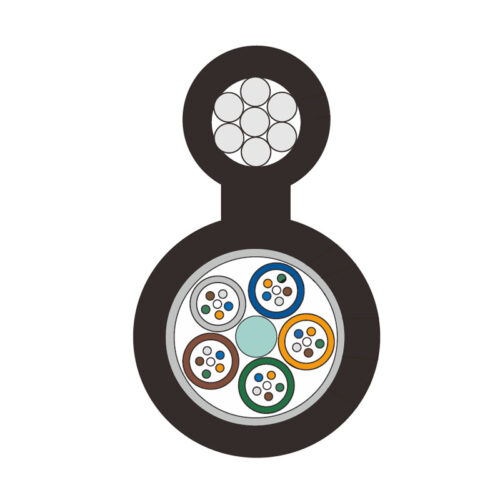

According to the structure, Figure 8 self-supporting aerial optical fiber cables are divided into uni-tube figure 8 fiber optic cable and stranded figure 8 fiber optic cable. Two parallel steel wires of the uni-tube figure 8 fiber optic cable ensure the tensile strength of the optical cable, and have the advantages of small diameter, light weight and easy laying. The stranded figure 8 fiber optic cable is filled and twisted together with gel between the loose tube and the reinforcing core, which ensures the waterproof performance between the loose tube and the reinforcing core.

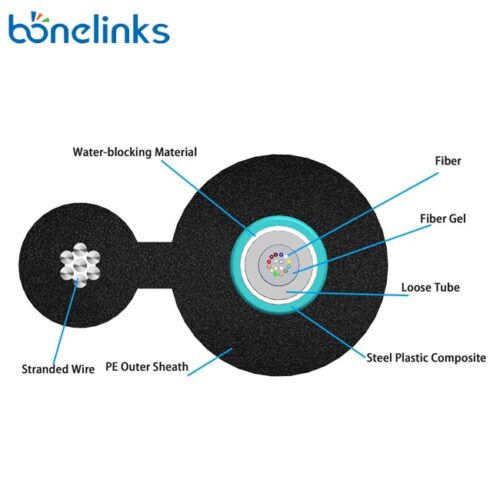

Armored Stranded Figure 8 Fiber Optic Cable

GYTC8A figure 8 fiber optic cable is a special structure, designed for medium and long-distance aerial installation outdoor fiber optic cable, the light armored self-supporting fiber optic cable has a special phosphate wire strand to provide suspension tension support, plastic-coated aluminum tape wrapping to block water vapor and enhance its own hardness. So whether it is secondary backbone line or metropolitan network construction, GYTC8A overhead laying section has superior performance. The minimum number of cores of figure 8 fiber optic cable designed and manufactured by Bonelinks is 2, and the maximum number of cores is 60, and the cable can be pre-assembled in different lengths according to the construction requirements.

- Good mechanical and temperature performance.

- High-strength loose tube that is hydrolysis resistant.

- The gel-free design is fully water blocked using craft-friendly water-swellable materials, making cable access simple and requiring no clean up.

- Crush resistance and flexibility.

- PSP enhancing moisture-proof.

- Two parallel steel wires ensure tensile strength

- Small diameter, light weight, and friendly installation

- Long delivery length

Armored Stranded Figure 8 Fiber Optic Cable

GYTC8A figure 8 fiber optic cable is a special structure, designed for medium and long-distance aerial installation outdoor fiber optic cable, the light armored self-supporting fiber optic cable has a special phosphate wire strand to provide suspension tension support, plastic-coated aluminum tape wrapping to block water vapor and enhance its own hardness. So whether it is secondary backbone line or metropolitan network construction, GYTC8A overhead laying section has superior performance. The minimum number of cores of figure 8 fiber optic cable designed and manufactured by Bonelinks is 2, and the maximum number of cores is 60, and the cable can be pre-assembled in different lengths according to the construction requirements.

- Good mechanical and temperature performance.

- High-strength loose tube that is hydrolysis resistant.

- The gel-free design is fully water blocked using craft-friendly water-swellable materials, making cable access simple and requiring no clean up.

- Crush resistance and flexibility.

- PSP enhancing moisture-proof.

- Two parallel steel wires ensure tensile strength

- Small diameter, light weight, and friendly installation

- Long delivery length

Armored Uni-Tube Figure 8 Fiber Optic Cable

GYXTC8S Figure 8 aerial fiber optic cable is a center bundle tube type aerial installlation outdoor fiber optic cable specially designed and produced for low number of access nodes and short suspension distance. This aerial Figure 8 fiber optic cable is one of the first cables to be considered for network communication projects in remote areas where the number of users is small and the construction and laying costs are to be controlled. The Figure 8 fiber optic cable is designed and manufactured by Bonelinks with a minimum of 2 cores and a maximum of 24 cores, and is designed to withstand not only its own weight, but also the fiber optic splice box suspended from the cable.

- Stranded loose tube design isolates optical fibers from installation and environmental rigors and facilitates midspan access

- CST armor to protect the cable from rodent attack and mechanical damage

- Low dispersion and attenuation

- Compact structure and lightness, flexible and good bend-resistant performance

- With small cable diameter, light cable weight, self-supporting

Customized Figure 8 Fiber Optic Cable

For Your Peace of Mind

We go beyond your expectation. Want to make customized figure 8 fiber optic cable? With flexibility and expertise being at the core of our comprehensive product customization service, we have a set of processes and services to meet your special requirements. Based on your need and our extensive experience. You name it, we make it!

Customized Materials & Specifications

For Figure 8 Fiber Optic Cable

No matter what specification for figure 8 fiber optic cable, at Bonelinks, You Can Choose Freely For Your Unique Request.

- 1 – 288 Core

- Single mode, Multimode

- OS1, OS2,OM2, OM3, OM4…

- G.652D;G.657.A1; G.657.A2 or other Customized Fiber Type

- Metallic, All dielectric…

- Unitube, MLT…

- Tensile, Crush, Span…

- 1km, 2km, 4km…

- Armored, Non armored…

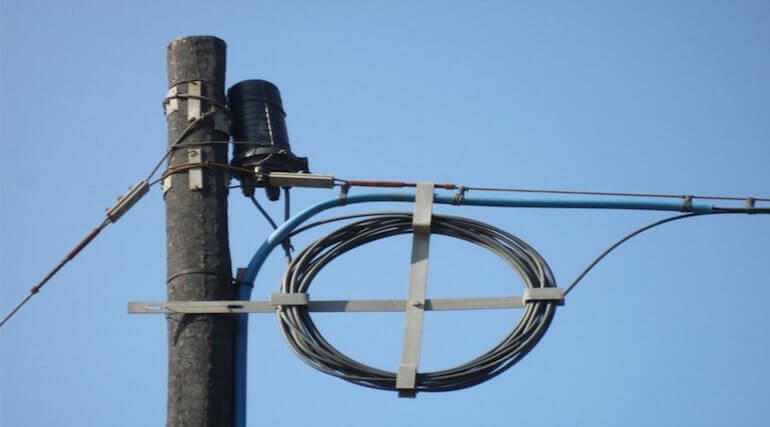

Figure 8 Cable Applications

Figure 8 fiber optic cable is self-supporting outdoor cable designed for aerial installation, suitable for long-distance communication and inter-office communication. Aerial laying between poles, between poles and buildings, between buildings and buildings can be realized very simply.

inter-office communication

Outdoor aerial application

long-distance communication

Your Competent

Figure 8 Fiber Optic Cable Supplier

Innovation, Quality, Service and Responsibility

- Our R&D team, skilled workers, advanced machines, and modern factories can provide our customers with outstanding quality service.

- On the flexibility

- High-quality control standard

- Plenty of Certificates of products and customs

- Professional expert team

- 24/7 Availability

Strict Quality Inspection with Industry Certifications

With the latest networking equipment, every product is 100% tested to guarantee long-term usage.

Compatibility Testing

Each transceiver has been tested for compatibility in end-use conditions to ensure interoperability and connectivity.

Performance Testing

Various performance testing procedures include optical power testing, optical spectrum evaluation, signal quality testing, and temperature testing.

Spec Testing

ATS system is equipped to automatically monitor every step of testing. Reliability & FA facility and equipment calibration ensure standard specs.

You Ask, We Answer

Figure 8 cable is a self-supporting fiber optic cable. With steel stranded wire as the self-supporting part of the fiber optic cable, it can meet very high tensile strength during installation and no need for hanging wire. The load of the optical cable is carried by the self-supporting fiber optic cable itself.

Yes. We will have a dedicated process engineer to interface with you to understand the specific situation and give our production advice.

Yes. We have Fujikura, Corning SMF 28e, and other brands fiber to choose from.

Yes. As long as we confirm the Pantone color code, we can produce the sheath color you request.

Yes. We can print company information or logos on fiber optic cables upon request.

The minimum order quantity of fiber optic cable is 1km. Because the outside diameter needs to be adjusted before producing.

This process will waste dozens of meters of raw material.

Under 100 km, it takes 4-5 days to produce. under 500 km, it takes 7-10 days to produce.

All fiber optic cables will come with a test report. If you encounter any quality problems, we replace them with new ones free of charge.

We have a special laboratory for high temperature, salt spray and vibration testing.

A supplier provides products,

but we care about your business.

If you do not find figure 8 fiber optic cables that can meet your requirements, please contact us as we might have a solution available.