Tight Buffer Fiber Optic Cable

Tight Buffer Fiber Cable

Tight-buffered fiber refers to optical fiber that is coated with an ultra-thin PVC coating to provide a certain level of protection against fiber breakage. This type of fiber is frequently employed as a constituent in larger fiber optic cables like distribution cables or breakout cables. It is also widely utilized as the preferred fiber in color-coded pigtail packs, which are used for fusion splicing.

Tight Buffer Cable Features & Benefits

- Quick and Simple Installation: Engineered with robust strength members to endure pulling stress without sustaining damage.

- Conduit-Free Installation: The interlocking armor feature adds an extra layer of protection, eliminating the need for conduit.

- Speedy Field Termination: The 900 µm tight-buffered cable has a small outer diameter (OD) and easily connects to FX Fusion Splice-On Connectors, enabling rapid field termination.

- Durable in Challenging Environments: The indoor/outdoor constructions incorporate materials that are resistant to UV and moisture exposure, ensuring longevity and reliability.

Tight Buffer Cable Vs Loose Tube Cable

Tight buffered and loose tubes are two styles of fiber optic cable construction.

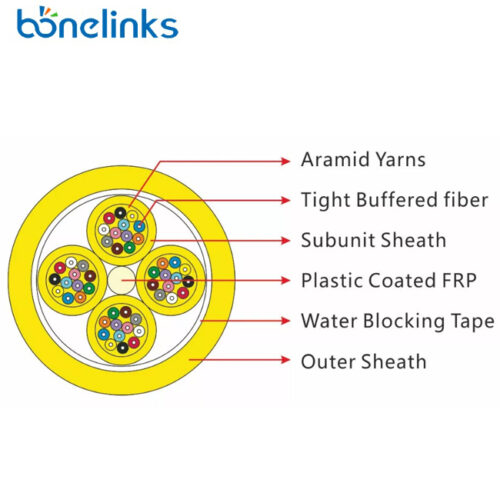

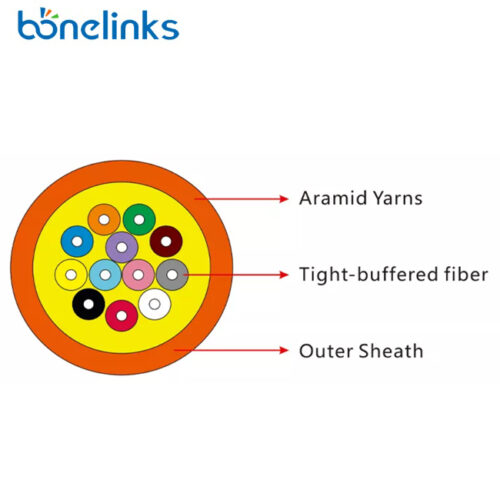

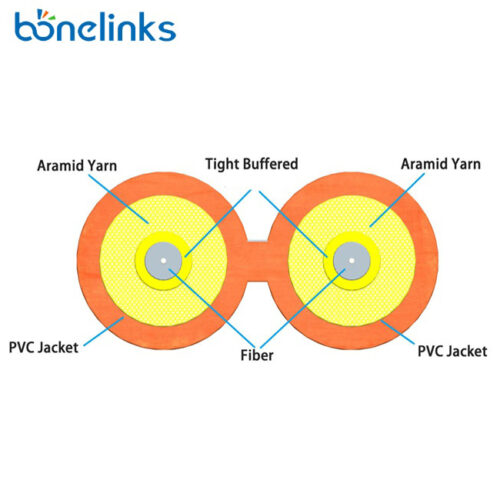

- Structure:Tight buffer fiber optic cable is generally constructed with 900μm buffered fibers surrounded by aramid yarn or e-glass strength members jacketed in an LSZH outer jacket. In loose-tube cables that hold more than one optical fiber, each individually sleeved core is bundled loosely within an all-encompassing outer jacket.

- Fiber counts: Tight-buffered fiber cable typically contains anywhere from 1 to 144 fibers, although those with 2, 6, 12, and 24 fibers are the most commonly employed. For particular applications, larger fiber counts like 48 fibers, 96 fibers, and 144 fibers are also obtainable. In contrast, the loose-tube fiber optic cable consists of 12 strands of fiber, but it can range from as little as 6 up to as many as 244 strands.

- Application:Tight-buffered cables are mainly designed for indoor applications. The tight buffer construction permits smaller sizes, and lighter-weight configurations, and is generally more flexible and crush-resistant. The main use of tight-buffered cable is within buildings and campuses, and is generally installed on cable trays or in conduits. Instead of a gel layer or sleeve to protect the fiber core, tight-buffered cables use a two-layer coating. One is plastic; the other is waterproof acrylate. Tight buffer fiber optic cable is also suitable for underwater applications owing to its two-layer coating. BTW, loose-tube gel-filled cable is the best for outdoor use, but since it’s inconvenient to be spliced and terminated, it’s not the first choice for indoor/outdoor use.

- Install: Tight-buffered cables are also easier to install because there’s no messy gel to clean up and they don’t require a fan-out kit for splicing or termination. You can crimp connectors directly to each fiber.

Learn more differences between tight buffered and loose tubes fiber.

- Fiber Breakout Cable

Breakout Tight Buffer Fiber Optical Cable Indoor Distribution Cable

- Fiber Breakout Cable

Distribution Fiber Optic Cable Single Mode Simplex Optical Fibre Bundle Cable

- Fiber Breakout Cable

Fiber Breakout Cable Indoor Multi Core Micro Optical Cable

- Fiber Breakout Cable

Fiber Optic Bundle Cable Indoor Breakout Pigtail

- Duplex Fiber Optic Cable

Fiber Optic Patch Cable Zipcord Duplex Cable Full-duplex Half-duplex

- Fiber Breakout Cable

Indoor Armored Fiber Cable

- Outdoor Fiber Optic Cable

Military Tactical Fiber Optic Cable

- Fiber Breakout Cable

Multi Core Breakout Armored Fiber Cable

- Indoor Fiber Optic Cable

Simplex Fiber Optic Cable Singlemode Multimode