Many different methods are used for cable installation. These include pulling, blowing, and pushing into ducts, direct burial, and aerial installation. In this article, Bonelinks will give you an overall aerial fiber optic cable installation guide.

The installation of aerial fiber optic cables can be a complex and time-consuming process due to the need to take into account potential damage from both natural and man-made causes. Regardless of the specific type of aerial fiber cable being used, the installation procedure remains largely the same.

Aerial Cable Installation Hardware

When you are balancing up high, you need to make sure everything is in perfect working order. That is why aerial installation requires a ton of different tools to make the job in the sky easy as can be! Some of the common tools include aerial storage for cables; telescoping poles; fiber heat shrink tube; brackets; blocks; cable saddles; fiber suspension clamp; cable rings, horizontal fiber splice closure, dome fiber splice closure, fusion splicers, etc.

Preparation for Installation

To ensure a smooth fiber optic installation process, it is essential to complete the following preparation tasks before commencing work:

1. Pre-Survey: This involves planning the cable route, which will determine the method of aerial cable installation to be used, as well as the necessary equipment and materials.

2. Installation Issues: Investigating ground conditions along the cable route, including clearance issues over roadways, driveways, trees or other obstructions. Sufficient clearance must be maintained between fiber optic cables and electrical power cables on joint-use poles. Existing dead-end pole must also be evaluated to determine their ability to withstand stresses during aerial cable installation. Temporary guying may be necessary to relieve temporary unbalanced loading during fiber optic installation.

3. Selection of Splice Locations: Selecting appropriate splice locations enables verification of the transmission design and preparation for cable order lengths. It is essential to ensure that the chosen locations do not lie in areas where access is difficult or hazardous.

By following these steps, careful planning and execution can help ensure that fiber optic network construction projects are completed efficiently and effectively.

Aerial Cable Installation Requirements

1. The distance between poles of overhead lines is 25- -40 meters in the urban area, 40-50 meters in the suburbs, and no more than 67 meters in other sections.

2. Overhead fiber optic cable should adopt a galvanized steel strand with the specification of 7/2.2mm as the suspension wire. For armored fiber optic cable, a steel strand with 7/2.0mm or /1.8mm can be used as well.

3. When comes to the sag of the aerial fiber optic cable, the elongation during the erection process and when it is subjected to the maximum load after erection should be taken into consideration.

4. A proper and stretched overhead fiber optic cable should be left on poles.

5. Erect the poles according to the design requirements, put the hanging wires, or use the original poles to renovate to meet the specified requirements.

6. The hanging distance of the optical cable hook is required to be 50 cm with an allowable deviation of no more than t3 cm. The overhead fiber optic cable clamps should be evenly hung and the hook pallets are complete. It is also crucial to choose different sizes of hook models for the outer diameter of various aerial fiber optic cables.

7. Bending of a fiber optic cable can damage the cable if the radius of the bend is too small. The normal recommendation for fiber optic cable bend radius is the minimum bend radius under tension during pulling is 20 times the diameter of the cable. When not under tension (after installation), the minimum recommended long term bend radius is 10 times the cable diameter.

Aerial Cable Installation Methods

There are two methods to install overhead fiber optic cables: the moving reel method and the stationary reel method.

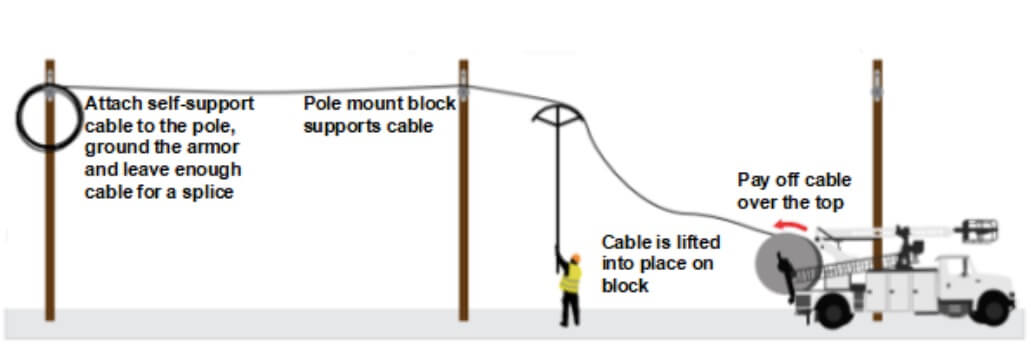

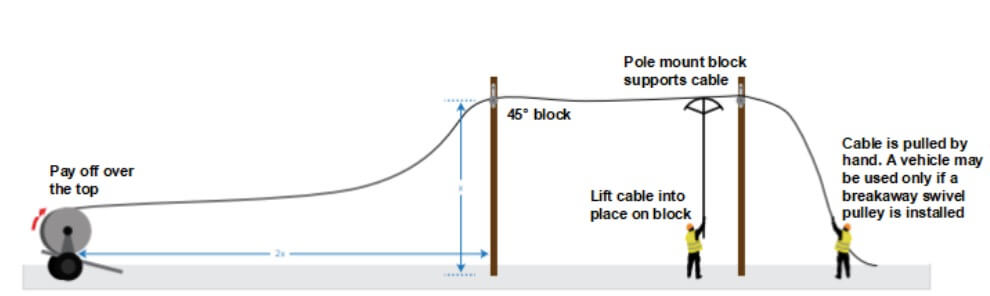

- Moving reel installation method: It is normally adopted when a cable reel trailer or aerial lift truck can be moved along the pole line and there are no obstructions to prevent raising the cable. It is a one-pass operation without requiring the use of cable blocks or pulls lines, saving time for the whole deployment.

- Stationary reel method: It is typically used when the route is not fully accessible by support vehicles. The cable is pulled into place from a stationary reel located at one end of the section run, and supported by temporary hardware. Once the cable is in position, it is transferred to the permanent support hardware.

Aerial Cable Termination Methods

When it comes to aerial cable, there are two primary methods for termination: field splicing and pre-termination. Each approach comes with its own set of advantages and disadvantages. For the final connection, many network operators opt for pre-terminated aerial cable to avoid the time and cost associated with fusion splicing. However, a drawback of using pre-terminated cable is the often-present excess cable after installation.

Fusion splicing, on the other hand, provides a high-quality fiber optic connection with minimal leftover cable once the process is finished. Despite its efficiency, this method demands time and requires specialized equipment and experienced engineers for execution. The complexity of preparing and splicing fibers is further heightened when the network access point is positioned at pole height.

Aerial Cable Installation Cost

It’s very difficult to estimate an exact price for an entire project to be wired. Example of aerial installation costs materials and labor excluding splicing based on a 288F cable.

- $15,420.00 to $21,588.00 per mile for the stand and lash method. Note –this type of construction would be located in the communications space on the pole.

- $23,647.00 to $33,106.00 per mile for ADSS construction. Note – Based on being constructed in the supply space on the pole.

Summary

Installing cables is not an easy thing, especially for aerial cable installations. Extra concentration and patience are needed during the fiber optic installation. The actual situation is usually much more complex than we talked about right here. You need to adjust your plans according to real conditions.