Fiber optic pigtail provides a fast way to make communication devices in the field. It is designed, manufactured and tested according to protocol and performance dictated by industrial standards, which will meet your most stringent mechanical and performance specifications. This article provides some basic but important knowledge of fiber optic pigtails.

What is Fiber Optic Pigtail?

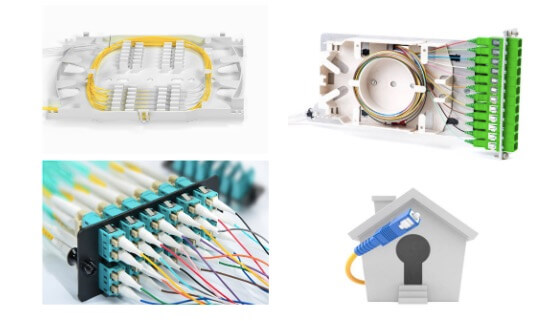

Fiber pigtail is a single, short, usually tight-buffered fiber optic cable with a factory-installed connector on one end, and un-terminated fiber on the other end. A fiber optic pigtail is used to splice each fiber in the trunk and “break out” the multi-fiber cable into its component fibers for connection to the end equipment. It usually appears in the fiber optic terminal box and is connected to other fiber optic cable cores by fusion splicing, which can simplify the installation and maintenance of the cable system.

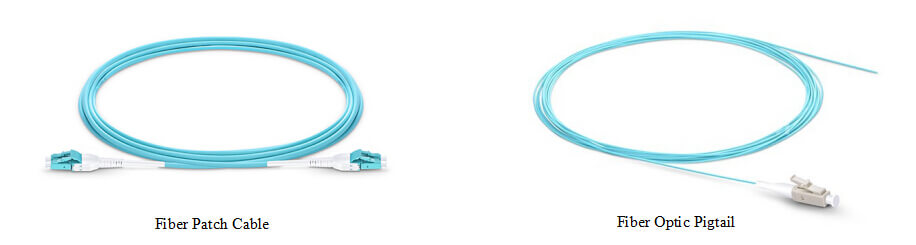

Fiber Patch Cords VS Fiber Optic Pigtails: What Is the Difference?

As connecting devices for optical network transmission, optical fiber patch cords and optical fiber pigtails have many similarities, which often make us confused.

- Fiber Connector

Pigtails have one terminated connector on one end and bare fibers on the other. Patch cords have pre-terminated connectors on both ends and no bare fibers. - Fiber Cable Types

Pigtails use unjacketed cables, like a 90μm diameter cable. Patch cords use jacketed fiber cables, such as 2.0mm or 3.0mm fiber. - Applications

Pigtails are mainly used for fast fusion splicing applications. Patch cords facilitate connectivity between optical transceivers, patch panels, and backbone networks. - Creating Pigtails

A simple method is cutting a fiber patch cord into two pieces to make two pigtails. Testing a pigtail in the field is challenging due to the unterminated end before splicing it to the equipment.

You can click to learn more about fiber pigtail VS the fiber patch cord.

Fiber Optic Pigtail Types

Fiber optic pigtails come in a variety of types, including LC, SC, and ST pigtails categorized by connector type, as well as single-mode and multimode fiber pigtails based on fiber type. In the market, you can find pigtails with different fiber counts, such as 6 fibers and 12 fibers, offering flexibility to meet various connectivity requirements.

By Connector Type

Fiber pigtails come in various types based on the connector used. Some common ones include LC pigtails, SC pigtails, ST pigtails, FC pigtails, MU pigtails, E2000 pigtails, and MPO pigtails. Let’s now explore these regular types in detail.

LC Fiber Pigtail

LC connectors are small form factor fiber connectors designed for high-density connections. They are 50% smaller than older SC connectors and feature a square plastic enclosure with a 1.25mm ceramic ferrule. LC fiber pigtails come pre-assembled with an LC connector and are widely used due to their compact size and commonality.

SC Fiber Pigtail

SC connectors, also known as Subscriber Connectors, have a 2.5mm pre-radiused zirconia or stainless alloy ferrule. SC fiber pigtails come pre-assembled with an SC connector. Due to their low cost, durability, and easy installation, SC pigtails are commonly used in both point-to-point (P2P) and passive optical network (PON) applications.

ST Fiber Pigtail

ST fiber pigtail resembles the FC pigtail but uses a locking mechanism instead of threads, making it distinct from FC connectors. It features a ferrule with an extended 2.5mm diameter made of ceramic (zirconia), stainless alloy, or plastic. As a result, ST pigtails are commonly applied in telecom, industry, medical, and sensor applications.

FC Fiber Pigtail

FC fiber pigtails utilize the metallic body of FC optical connectors, featuring a screw-type structure and high-accuracy ceramic ferrules. They find extensive use in various applications.

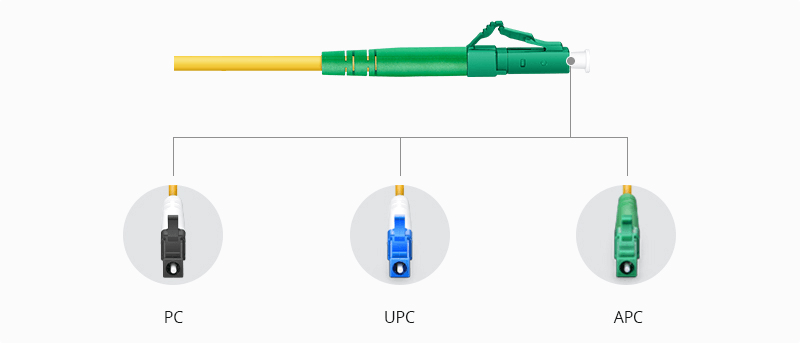

By Interface Polish Type

Fiber optic pigtails come in PC, UPC, and APC versions, e.g., SC/APC, SC/UPC, LC/APC, etc.

PC Fiber Pigtail

PC stands for “physical contact” connector, featuring a physical contact polished connector. PC fiber pigtails are commonly used in the telecom sector and data systems, especially for multimode applications.

UPC Fiber Pigtail

UPC stands for “ultra physical contact”. This type of pigtail uses a UPC connector with improved physical contact, reducing air gaps and lowering optical return loss (ORL). It is the most common polish type for both single mode and multimode pigtails.

APC Fiber Pigtail

APC stands for “angled physical contact”. These pigtails are designed to further reduce back reflection. The ferrule end faces of APC connectors are polished at an angle of 8 degrees, making them ideal for CATV, FTTx, and WDM systems.

By Fiber Type

Fiber optic pigtails are categorized into single-mode (colored yellow) and multimode (colored orange) fibers.

Multimode Fiber Pigtail

It utilize 62.5/125 micron or 50/125 micron bulk multimode fiber cables, terminated with multimode connectors at one end. For higher data rates, 10G multimode pigtails (OM3 or OM4) are available, typically identified by an aqua jacket color.

Single-mode Fiber Pigtail

It use 9/125 micron single-mode fiber, terminated with single-mode connectors at one end. These pigtails are commonly used for long-distance transmissions and specialized applications requiring high performance.

By Fiber Count

Fiber optic pigtails come in various fiber counts, including 1, 2, 4, 6, 8, 12, 24, and 48 strands. Simplex pigtails have one fiber with a connector on one end, while duplex pigtails have two fibers and two connectors on one end, marked as “A” and “B” or with different colored connector boots for polarity. Similarly, pigtails with 4, 6, 8, 12, 24, 48, and more than 48 fibers each have their corresponding features.

By Fiber Constructer

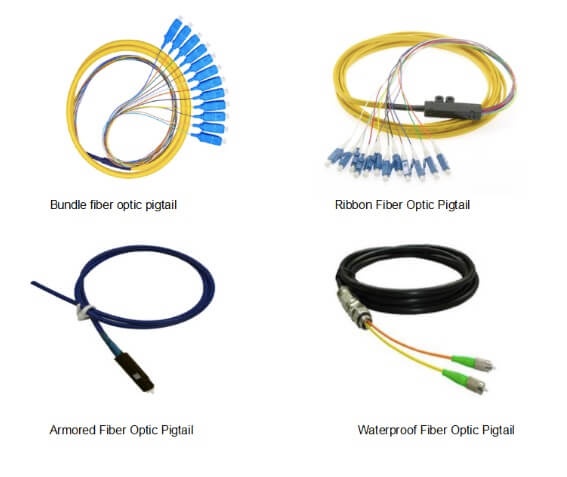

Fiber pigtails can be categorized based on their fiber cable structure, including multi-fiber bundle pigtail, multi-fiber ribbon pigtail, 0.9mm pigtail, and 2.0/3.0mm pigtail.

By Application Environment

Fiber pigtails are categorized by application environment into three types: Regular Indoor Pigtail, Armored Pigtail, and Waterproof Pigtail.

Regular Indoor Pigtail

No extra protection, cost-effective, suitable for indoor use with a tighter bend radius.

Armored Pigtail

Stainless steel tube inside the outer jacket for protection against damage from rats, construction, and cable weight.

Waterproof Pigtail

Rugged connectors, stainless steel reinforcement, and armored outdoor PE jacket for protection in harsh outdoor environments like communication towers and military applications.

By Sheath Material

Optical fiber pigtails are categorized into three types based on their materials: PVC, LSZH, and OFNP.

PVC Fiber Pigtail

It is the most common and affordable option with average fire resistance.

LSZH Fiber Pigtail

It offers better flame retardant properties but comes at a higher cost than PVC.

OFNP Fiber Pigtail

It provides the best flame retardant performance and is ideal for data center applications, though it is the most expensive option.

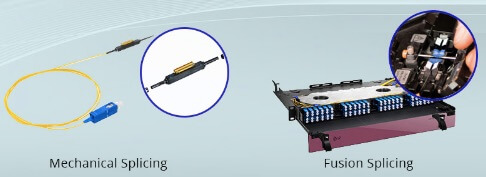

Fiber Optic Pigtail Splicing

Fiber pigtails have high quality as they are factory-terminated, ensuring accuracy compared to field-terminated cables. They can be attached using mechanical or fusion splicing.

- Mechanical splicing: Strip the laying optical fiber and pigtail fiber, cut it, clean it, and insert it into the splice matching disc to align, tangent and lock.

- Fusion splicing: Use auxiliary tools to strip the laying optical fiber and pigtail fiber, cut it, clean it, and then use an optical fiber fusion splicer under the protection of a fusion splicer to “melt” into one.

Summary

The above is a detailed intro to fiber pigtails. The application of fiber pigtails can be seen everywhere, but the most common application is the combination of other optical components. It is widely used in telecom equipment rooms and data centers and can meet the connection requirements of Gigabit Ethernet, 10 Gigabit Ethernet and high-speed fiber channel networks. Please contact us if you need fiber pigtails.