The MTP® fiber connector has found extensive use in high-density network setups, including data centers, broadcast communications, and industrial control applications. Its introduction has been warmly received by numerous network installers, particularly for high-speed network systems like 40G, 100G, and 400G. Are you familiar with the intricacies of this high-performance, high-density cabling solution? This post aims to provide you with a comprehensive introduction to the MTP® fiber connector, along with related information.

What Is MTP® and MPO Connector?

MPO (Multi-Fiber Push On) cables are terminated with MPO connectors on both ends. The MPO fiber connector is specifically designed to offer multi-fiber connectivity within a single connector, making it ideal for supporting high bandwidth and high-density cabling system applications. The MPO connector conforms to the IEC 61754-7 standard and the U.S. TIA-604-5 standard. Currently, MPO connectors are commonly available in configurations of 8, 12, 16, or 24 fibers for typical data center and LAN applications. For specialized super high-density multi-fiber arrays, larger counts such as 32, 48, 60, and 72 fibers are also achievable in large-scale optical switches.

MTP® cables, which stand for Multi-Fiber Pull Off cables, feature MTP fiber connectors at both ends. The MTP® connector, developed by US Conec, is an upgraded version of the MPO connector with enhanced specifications. This means that MTP connectors are entirely compatible with generic MPO connectors and can seamlessly connect with other infrastructure built upon MPO technology. Nevertheless, the MTP connector is an advancement that incorporates multiple engineering enhancements to elevate both the mechanical and optical performance beyond what is achieved by standard MPO connectors.

What are Male MTP Connectors and Female Connectors?

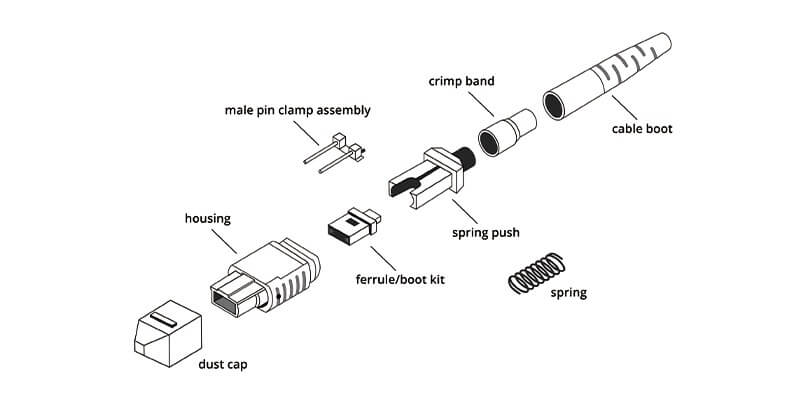

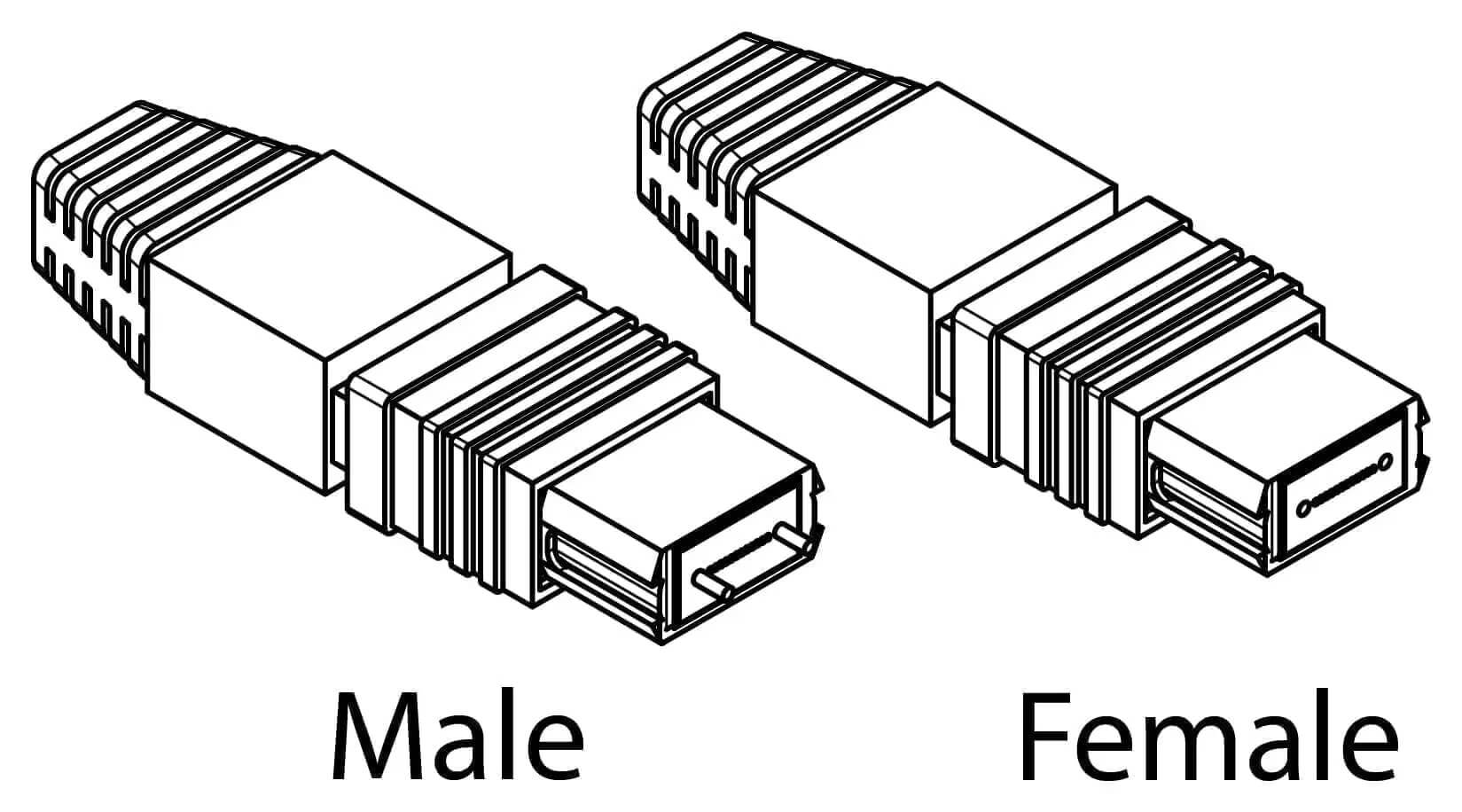

The MTP optical fiber connector comprises various components like optical fiber, sheath, coupling elements, metal ring, pin (PIN needle), and dust cap. Within the pin section, there are two forms: male and female. The male connector consists of two pins, while the female connector lacks these pins. Precise alignment of MTP fiber connectors is achieved via these pins, and when connecting two MTP connectors together, one must be male and the other female. In an MTP system, the gender (male/female), orientation (KeyUp/KeyUp or KeyUp/KeyDown), and end face alignment (straight or angled) collectively influence the MTP polarity.

What is MTP Polarity?

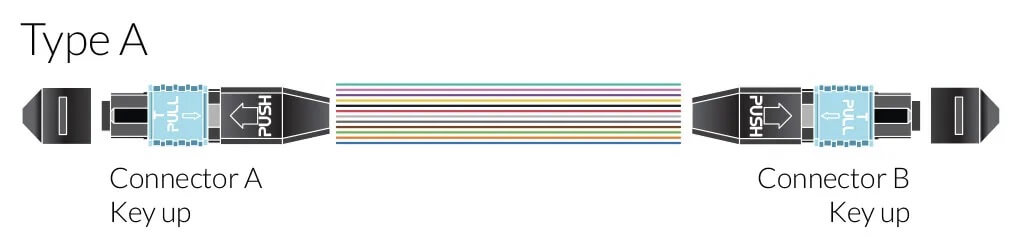

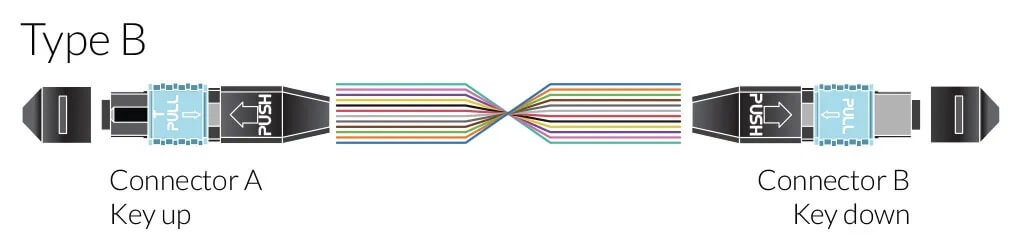

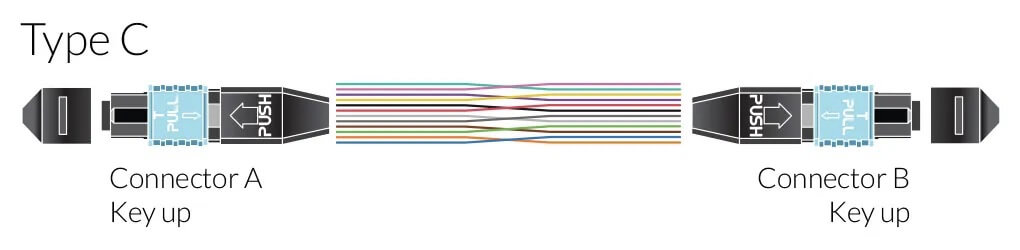

Polarity refers to the alignment from the transmitter (Tx) to the receiver (Rx) within an optical fiber link. Proper transmission occurs only when the fiber connector is aligned with the correct polarity. The TIA-568 standard approves three polarity configuration methods—Type A, Type B, and Type C. These methods are used for different MTP trunk cables, ensuring optimal connectivity.

Why Choose an MTP Connector?

MPO fiber connectors and MTP fiber connectors share the same form factor and multiplex push-pull coupling (SNAP) mechanism. However, MTP connectors, developed by US Conec, offer distinct design features that elevate both optical and mechanical performance. Here are the noteworthy characteristics:

Simple and Fast Installation

The MTP system stands out with its expedited installation process, reducing installation time by up to 75% compared to traditional fiber systems. This efficiency is attributed to the MTP cable connector’s removable housing. This design not only facilitates re-working and re-polishing of the MT ferrule but also enables swift gender transitions from male to female. Whether pre-assembled or not, MTP connectors with removable housing provide convenient solutions for users.

Enhanced Density in Compact Space

As the need to accommodate more fibers in smaller areas arose, the challenge for installers grew. MTP connectors effectively tackled this issue. Even preceding the widespread use of parallel optics, there was a struggle to facilitate high-density applications. MTP connectors provided a streamlined solution for precisely this purpose. Instead of relying on a 1U housing with duplex connections accommodating 144 fibers, the MTP housing exhibited a remarkable capacity of 864 fibers — a substantial sixfold increase in capability. This exceptional fiber density positioned MTP connectors as an ideal fit for data centers confronted with stringent space restrictions and/or substantial volumes of cables.

Flexibility

MTP fiber connectors offer four standard variations of strain relief boots, providing versatility in cable applications. Moreover, these flexible strain relief boots allow cables to stretch and bend in various positions, ranging from 0 to 90 degrees. This feature greatly enhances cable management, especially in confined setups.

Stability

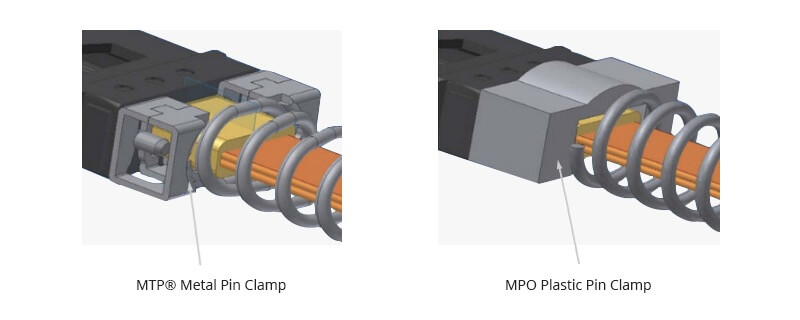

Inside the MTP cable connector, a metal pin clamp ensures the prevention of lost pins and centers spring force. The spring design optimizes ribbon clearance for multi-fiber ribbon applications, safeguarding against fiber damage.

The MTP connector utilizes thermoplastic-molded ferrules that exhibit resilience to temperature variations. This material sustains a consistent diameter for the guide holes, contributing to more reliable physical connections.

A slidable locking structure characterizes the MTP connector, allowing the two connectors to maintain robust physical contact with the ferrule even in the presence of external forces during connection.

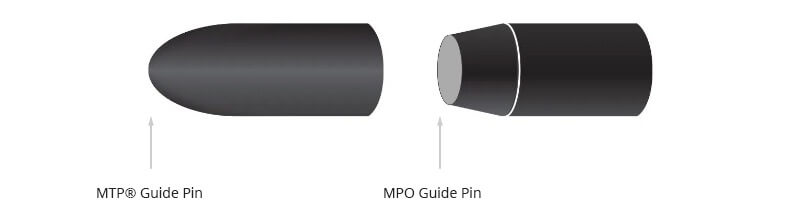

Years of experience have led to refinements in the alignment guide-pin design. This optimized elliptical guide-pin significantly minimizes wear and dust accumulation in the guide hole due to repeated insertions and removals, enhancing overall stability and durability.

FAQs on MTP Connectors

Q: What is the MT ferrule?

A: The term “MT” stands for “Mechanically Transferable.” The MT ferrule is a type of plastic ferrule designed for handling multiple fibers. It features a square end-face with dimensions of 6.4×2.5mm and a fiber pitch of 0.25mm. This MT ferrule is commonly employed in MPO/MTP connectors. Unlike ferrules used in other fiber connectors, the MT ferrule within an MPO/MTP connector is crafted from a single, high-precision, glass-filled polymer material instead of ceramic. This design allows the MT ferrule to effectively connect multiple fibers through advanced precision and high-density technology, ensuring minimal signal loss in each fiber.

Q: Is the MTP connector an MPO connector?

A: Yes, the MTP connector is a high-performance version of the MPO connector, designed for improved mechanical and optical performance. It’s important to note that while all MTP connectors are MPOs, not all MPO connectors are MTPs.

Q: What is an MTP Elite?

A: The MTP Elite variant offers lower insertion loss compared to the standard MTP fiber optic cable. When mated, the maximum insertion loss is 0.35 dB for multimode fiber cables (compared to 0.6 dB) and 0.35 dB for single-mode fiber cables (compared to 0.75 dB).

Q: What is an MTP Pro cable?

A: An MTP PRO patch cord is pre-terminated with MTP PRO connectors and factory-polished for exceptional low loss performance. The MTP PRO connector introduces a novel design that ensures simplicity, reliability, and quick polarity and pin reconfiguration in the field, all while maintaining product integrity and performance.

Q: How to clean MTP connectors?

A: Cleaning fiber connectors is crucial both during manufacturing and when using them, including MTP connectors. Cleaning MTP connectors involves three key steps: inspect, clean, and reinspect.

- Inspect: Use a microscope to carefully check the end faces of both mating MTP connectors. Eliminate any dust or debris, as contamination can spread between connectors.

- Clean: Utilize dedicated MTP cleaning tools to gently clean the end faces. Ensure thorough cleaning until contaminants are removed.

- Reinspect: After cleaning, use the microscope again to verify that both connectors are clean and ready for use.

Maintain a clean environment to prevent contamination transfer. By following these steps, you’ll optimize the performance of your MTP connectors.

Conclusion

The MTP fiber connector, along with the MTP cabling system, offers a straightforward and dependable solution for optical fiber cabling needs.

The MTP connector’s ability to substantially reduce insertion loss during connector mating results in improved efficiency for optical fiber networks, particularly in scenarios with high data transfer rates such as 40G and 100G. Consequently, MTP emerges as the optimal connector for environments demanding the utmost performance currently available. Given its effectiveness and forward-looking attributes, the MTP fiber connector is poised to thrive in a multitude of network applications in the coming years.