What is Linear Drive?

In the past two years, the concept of linear drive has gained tremendous attention and popularity. Whether it is Arista’s conference reports or the subsequent feedback and launch of related products by major semiconductor manufacturers, linear drive pluggable optics (referred to as LPO below) is steadily landing in the market.

Challenges of DSP in High-Speed Optical Modules

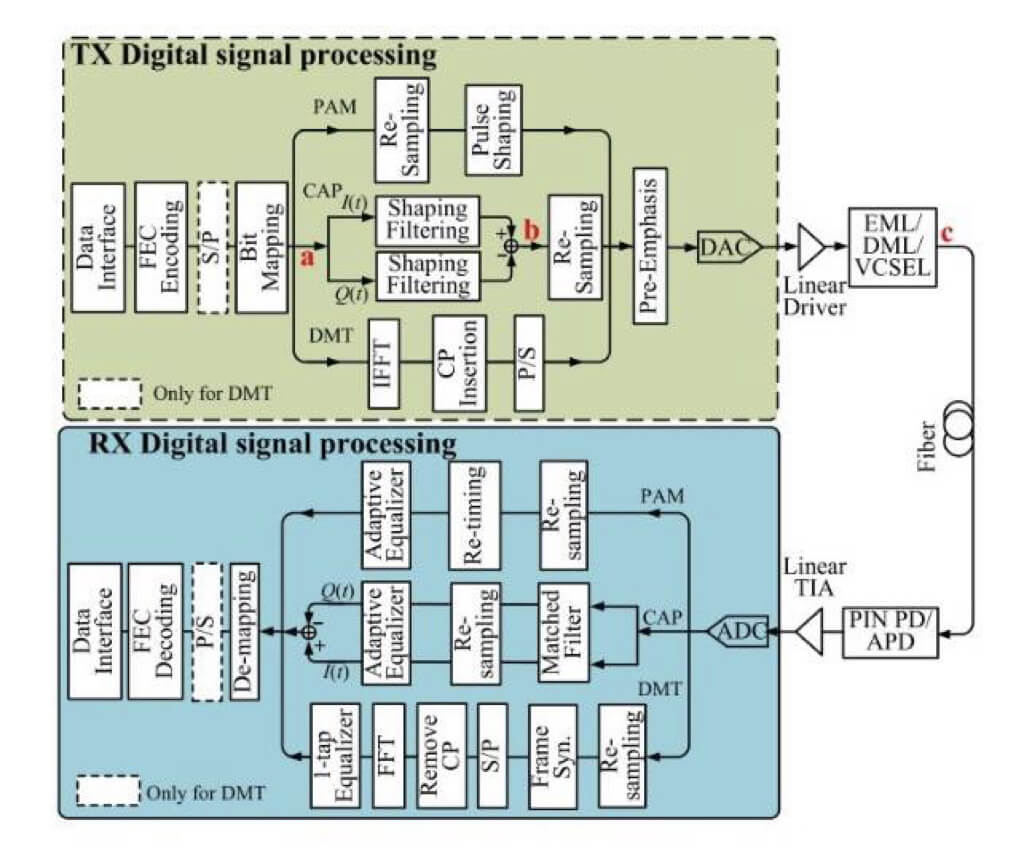

In current high-speed optical modules, DSP chips are typically introduced for signal processing of high-speed signals. The main functions include: 1) ADC/DAC, 2) FEC, 3) retiming, 4) reshaping, 5) adaptive equalizer, and so on, as shown in the figure below.

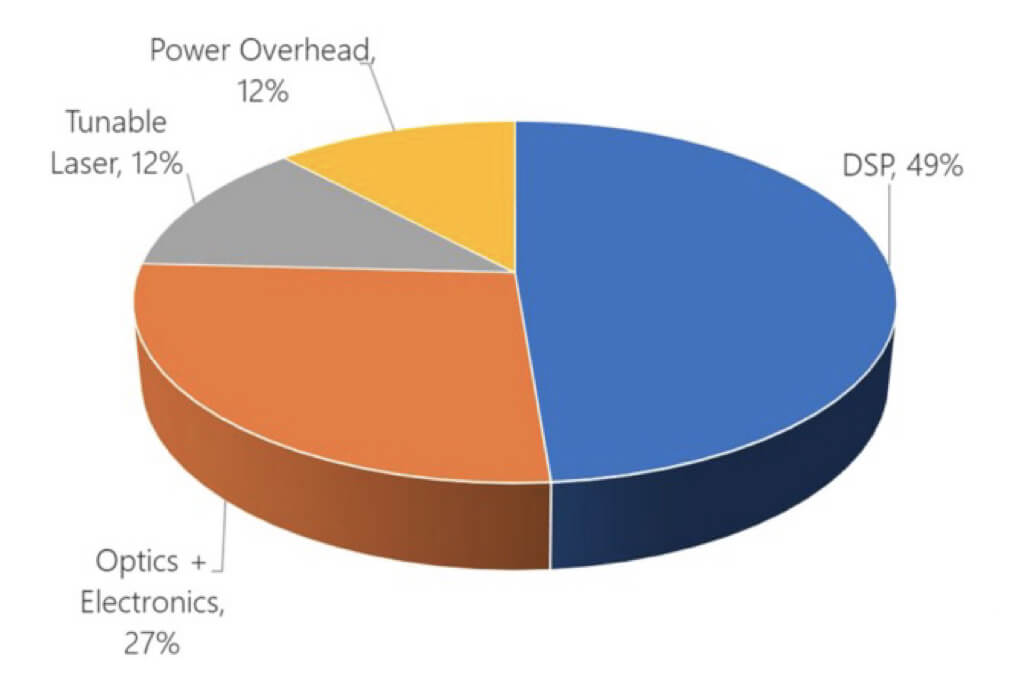

Although DSP is powerful in functionality, it also brings significant power consumption and cost overhead, acting as a double-edged sword. The 7nm DSP used in 400G optical modules has a power consumption of about 4W, accounting for 50% of the entire module’s power consumption. The following figure shows the power breakdown of a 400G ZR optical module, and the situation is similar for IMDD (Intensity Modulated Direct Detection).

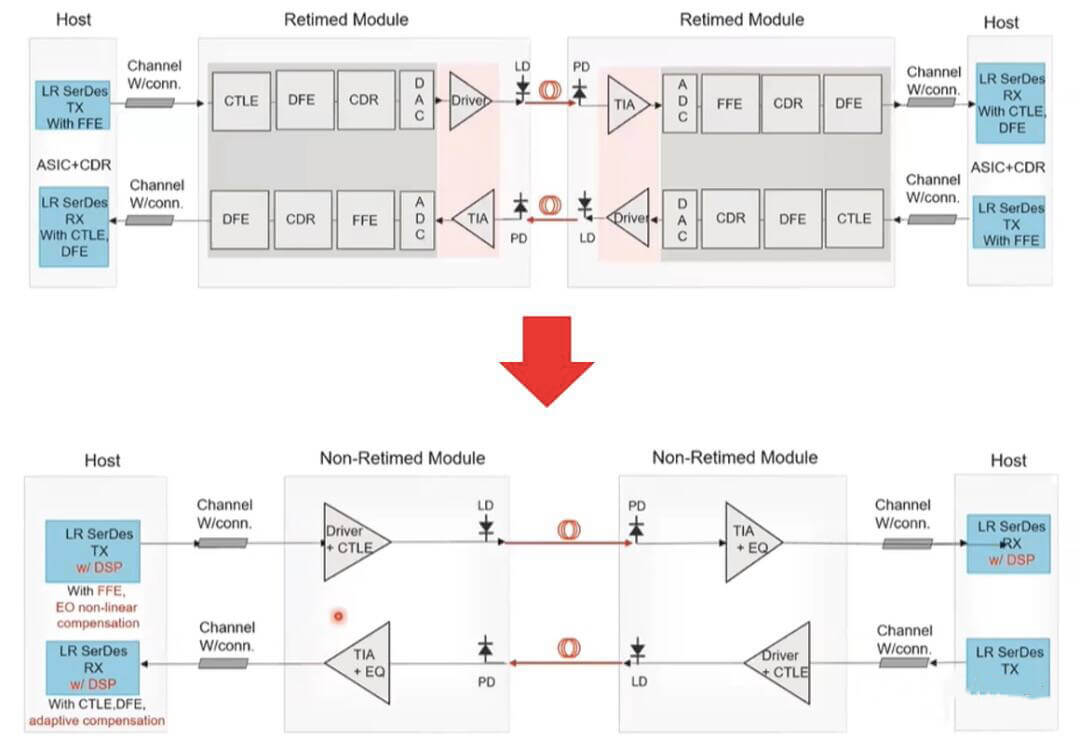

How to eliminate the power consumption and cost impact caused by DSP? The concept of linear drive has emerged. In optical modules, DSP is no longer used; only the driver and TIA are retained, with DSP functionality integrated into the switching chip, as shown in the figure below. In the optical module, the semiconductor chip only contains the driver and TIA. Unlike traditional driver and TIA setups, the driver and TIA in LPO need to integrate CTLE and Equalization functions separately to compensate for high-speed signals to some extent. The main function of the driver is linear amplification (linear amplifier), and the output voltage varies linearly. The signals emitted by the switch no longer need to be restored through CDR (clock data recovery), but are directly transmitted to the driver. Retiming is a nonlinear process, and LPO is also referred to as a Non-retimed module.

Linear-Drive Pluggable Optics (LPO) Advantages

The main advantages of LPO are as follows:

- Low Power Consumption

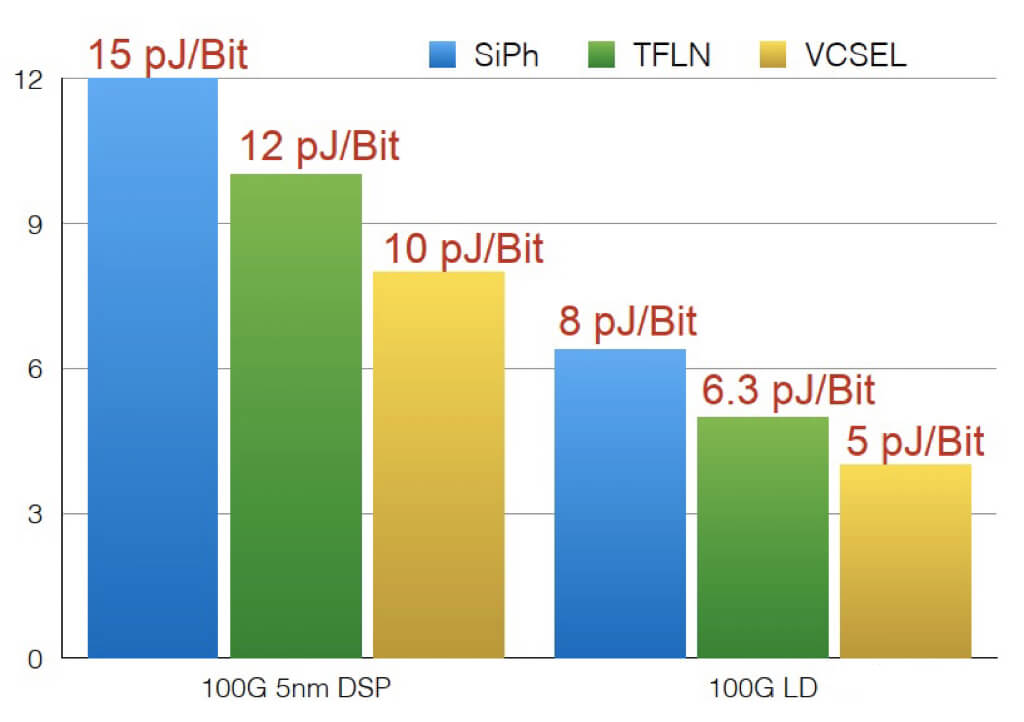

Compared to pluggable optical modules, LPO reduces power consumption by approximately 50%, approaching the power consumption of CPO. The figure below shows Arista’s power consumption comparison for different optical solutions. After adopting the Linear-drive scheme, the power consumption of various schemes (silicon photonics, VCSEL, TFLN thin film lithium niobate) decreases by around 50%.

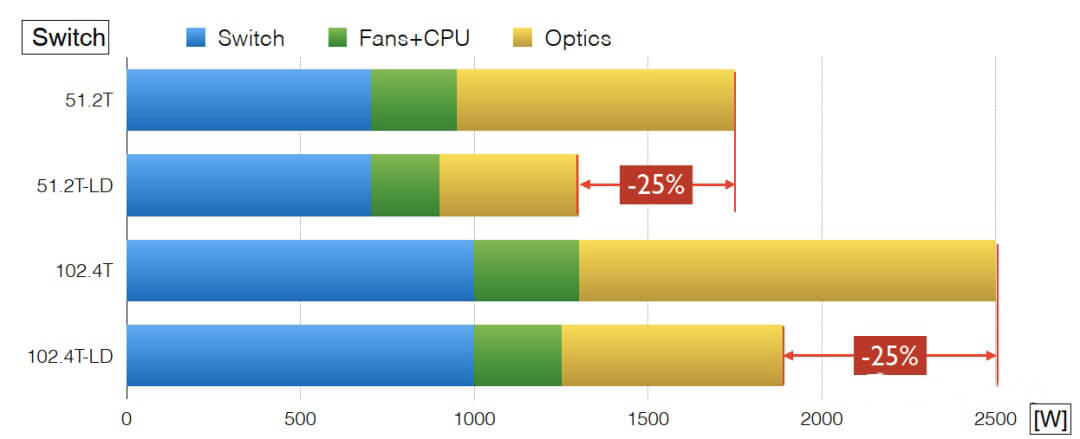

The overall power consumption of the switch system is reduced by about 25%, as shown in the following figure.

- Low Latency

Due to the absence of DSP and the elimination of signal recovery, the latency of the entire system is significantly reduced. This makes it suitable for applications with high latency requirements, such as interconnecting GPUs in High-Performance Computing (HPC) centers. - Low Cost

Since there is no longer a need for DSP chips with 5nm/7nm technology, the system cost is reduced. According to some data extracted from research reports, in an 800G optical module, the Bill of Materials (BOM) cost is approximately $600-700, while the cost of the DSP chip is around $50-70. The integration of EQ functionality into Driver and TIA increases the cost by 3-5 dollars. The overall system cost reduction is around 8%. - Hot-Pluggable

Due to factors such as reliability and cost, CPO has not been widely adopted. In comparison to CPO, LPO still adopts the form of pluggable modules, ensuring high reliability and convenient maintenance. It can leverage a mature optical module supply chain. This is also one of the significant reasons why the LPO solution is favored; it avoids significant packaging form innovations, as seen in CPO.

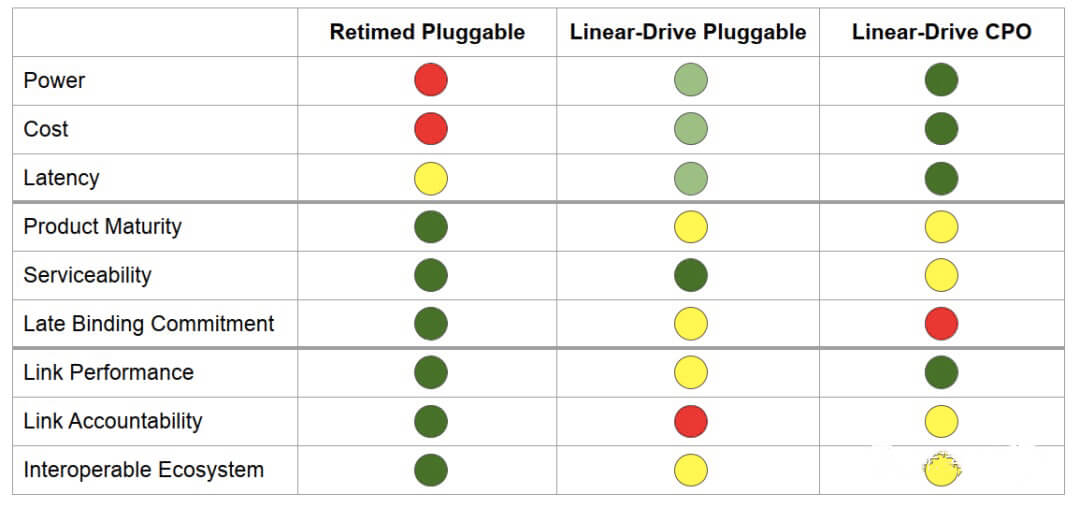

Comparison with Traditional Optical Modules and CPO

The following figure compares various dimensions of traditional optical modules, LPO, and CPO.

Challenges and Considerations for LPO Implementation

Certainly, as a new technological solution, LPO still faces several challenges that need to be addressed. Typical issues include:

- The need to integrate DSP chips into switches, requiring the support of switch chip manufacturers. The LPO solution has also disrupted the market share of DSP chip manufacturers (Broadcom and Inphi).

- The necessity to define new protocols and testing methods, with OIF currently defining the CEI-112G-LINEAR standard.

- The applicable scenarios for LPO and whether it can achieve kilometer-level distances. Since there is no DSP chip in the module, the system’s bit error rate may decrease, leading to a reduction in transmission distance.

Current Status of LPO Implementation

The introduction of the LPO solution reflects the demand for low-power, low-cost, high-speed optical modules. However, currently, the LPO solution is more in the stage of technical discussions and has not yet been finalized, nor has it entered the mass production stage.