According to the applicable scenarios, optical cables are generally classified into several major categories, including outdoor, indoor, and indoor/outdoor. What are the differences among these major categories of optical cables?

1. Outdoor Optical Fiber Cable

The most common type of cable we encounter in communication engineering is usually outdoor optical fiber cable.

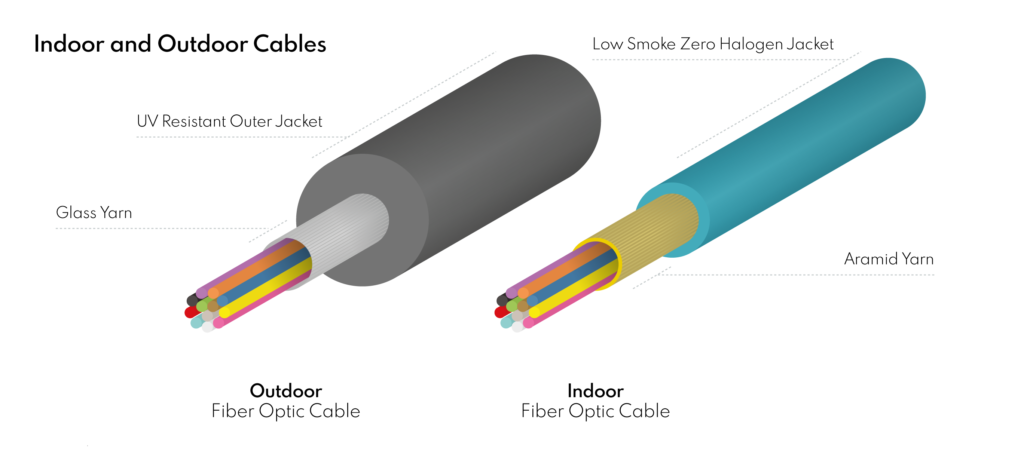

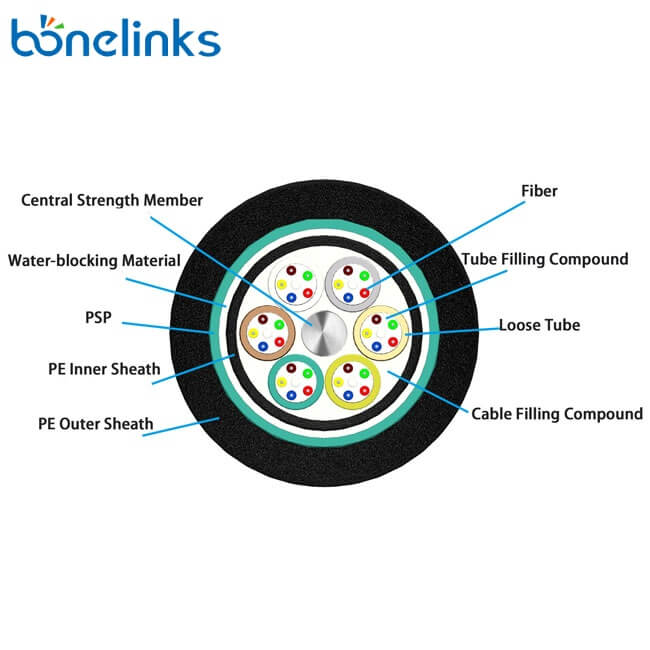

To meet the usage requirements of outdoor environments, outdoor optical fiber cables generally possess good mechanical performance and commonly employ moisture-proof and water-resistant structures. To enhance the mechanical performance of the cable, outdoor optical fiber cables often incorporate metal components such as metal central strength members and metal armor layers. The plastic-coated aluminum or plastic-coated steel tapes around the cable core exhibit excellent moisture-blocking properties. Waterproofing of the cable is mainly achieved by adding grease or water-blocking yarn as fillers within the cable core.

The sheath of outdoor optical fiber cables is typically made of polyethylene. Polyethylene sheaths have excellent physical properties, corrosion resistance, long lifespan, good flexibility, and other advantages, but they are not flame-retardant. Carbon black and other additives are generally included in the sheath to enhance its resistance to ultraviolet radiation. Therefore, outdoor optical fiber cables that we see are often black in color.

2. Indoor Optical Fiber Cable

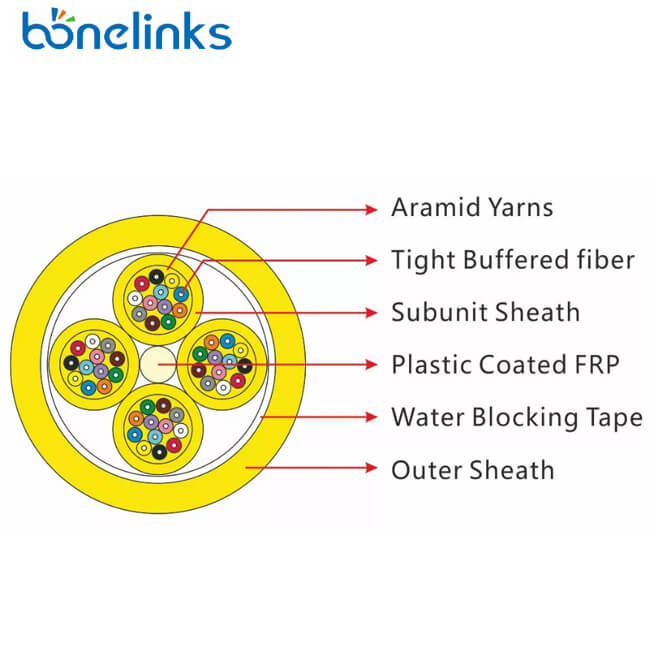

Indoor optical fiber cables generally feature a non-metallic structure, with aramid fibers commonly used as the cable’s strength member, contributing to enhanced flexibility.

The mechanical performance of indoor optical fiber cables is typically lower than that of outdoor cables. For instance, when comparing indoor cables designed for vertical cabling with better mechanical performance to outdoor cables used in weaker mechanical environments such as pipes and non-self-supporting aerial cables, indoor cables have better allowable tensile force and allowable flattening force.

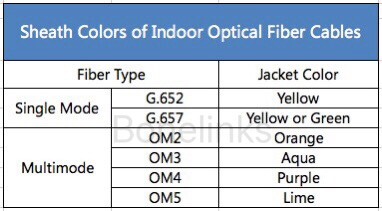

Indoor optical fiber cables usually do not require considerations for moisture-proofing, water resistance, or UV resistance. Therefore, the structure of indoor cables is much simpler than that of outdoor cables. The sheath of indoor optical fiber cables comes in a variety of colors, typically corresponding to the types of fiber optic cables, as shown in the figure below.

Compared to outdoor cables, indoor optical fiber cables have shorter spans and often require termination at both ends. Therefore, indoor cables commonly appear in the form of patch cords, where the middle section is the indoor optical fiber cable. To facilitate termination, the fiber cores of indoor cables usually consist of tight-buffered fibers with a diameter of 900μm (while outdoor cables typically use colored fibers with diameters of 250μm or 200μm).

Due to deployment in indoor environments, indoor optical fiber cables must possess certain flame-retardant capabilities. Depending on the flame-retardant rating, the cable sheath employs different flame-retardant materials, such as flame-retardant polyethylene, polyvinyl chloride, low-smoke zero halogen flame-retardant polyolefin, etc.

3. Indoor/Outdoor Optical Fiber Cable

Indoor/outdoor optical fiber cable, also known as universal indoor/outdoor cable, is a type of cable designed to be used both outdoors and indoors, serving as a conduit for optical signals from outdoor to indoor environments.

Indoor/outdoor optical fiber cables need to combine the advantages of outdoor cables, such as moisture resistance, water resistance, good mechanical performance, and UV resistance, with the characteristics of indoor cables, including flame retardancy and electrical non-conductivity. This type of cable is also referred to as a dual-purpose indoor/outdoor cable.

Improvements made to indoor/outdoor optical fiber cables, based on outdoor cables, include:

Improvements made to indoor/outdoor optical fiber cables, based on outdoor cables, include:

- The use of flame-retardant materials for the sheath.

- The absence of metallic components in the structure or the use of metallic reinforcement components that are easily electrically disconnected (such as the messenger wire in self-supporting cables).

- Implementation of dry waterproofing measures to prevent grease leakage when the cable is vertically deployed.

In conventional communication engineering, indoor/outdoor cables are rarely used except for FTTH (Fiber to the Home) drop cables. However, in comprehensive cabling projects where optical cables commonly transition from outdoor to indoor environments, the use of indoor/outdoor cables is more frequent. Two common structures of indoor/outdoor cables used in comprehensive cabling projects are the loose-tube structure and the tight-buffered structure.

4. Can Outdoor Optical Fiber Cables be Used Indoors?

No, they cannot. However, in conventional communication engineering, due to the majority of optical cables being deployed outdoors, situations where outdoor optical cables are directly routed indoors are quite common. In some cases, even crucial connections such as the drop cables for core data centers or communication cables between different floors of a core data center use outdoor optical cables. It poses significant fire safety risks to the building, as outdoor cables may not meet the indoor fire safety standards.

5. Recommendations for Selecting Optical Fiber Cables in Building Infrastructure

- Applications Requiring Both Indoor and Outdoor Deployment: For cable applications requiring deployment both outdoors and indoors, such as drop cables and cables entering the building, it is advisable to opt for indoor/outdoor optical fiber cables.

- Applications Entirely Deployed Indoors: For cable applications entirely deployed indoors, consider using either indoor optical fiber cables or indoor/outdoor optical fiber cables.

- Consideration of Fire Safety Requirements: To meet fire safety standards, carefully select indoor/outdoor optical fiber cables and indoor optical fiber cables with appropriate flame-retardant ratings.

These recommendations aim to ensure that the selected optical fiber cables are well-suited for their specific deployment scenarios within the building infrastructure. They take into consideration both indoor and outdoor requirements while prioritizing compliance with fire safety standards.