Fiber optic cables play a vital role in optical networking, yet the complexity of fiber color codes often leaves technicians seeking clarity. This comprehensive guide unveils the standard color code and equips beginners with the knowledge to easily identify them.

How Color Codes Are Used In Fiber Optics

Fiber optic color codes are essential for identifying fiber cables, connectors, and individual fibers, offering multiple benefits in indoor and outdoor applications.

- Ease of Installation: Correct color-coding simplifies cable identification, saving time and resources during installation.

- Ease of Maintenance: Color codes enable easy identification of fibers for repair or replacement after installation.

- Simplified Splicing: Color-coded fibers streamline the selection of strands for splicing, ensuring continuity in cable runs.

- Fewer Human Errors: Color coding reduces the risk of mistakes in identifying fibers, minimizing misconnections, even in complex setups.

- Port Separation: Color codes facilitate efficient separation of fiber optic cables into different ports when necessary.

Understanding Fiber Optic Color Codes: TIA-598 Standard

Color codes play a crucial role in rapid identification of fibers, cables, and connectors. The Telecommunications Industry Association (TIA) has introduced the TIA-598 standard, providing guidelines for manufacturers to establish and reference fiber color codes. Adhering to this standard ensures consistency and facilitates efficient identification, installation, and maintenance processes in the fiber optic industry.

Simplifying Fiber Optic Color Codes: Three Essential Categories

Three vital categories comprise fiber optic color codes: Cable Jacket, Inner Fiber, and Connector. Simplifying identification and maintenance processes for fiber optic systems.

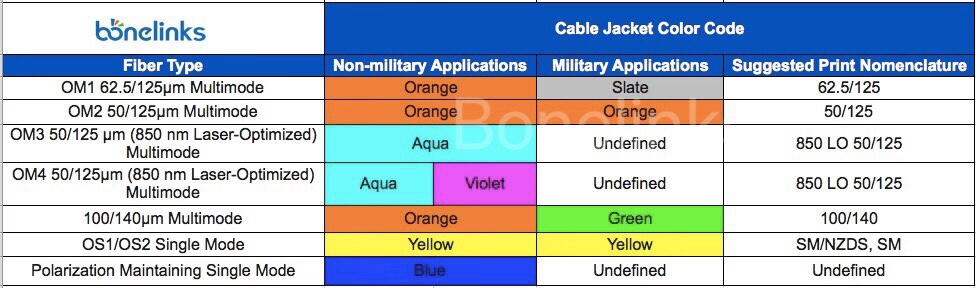

Cable Jacket Color Code

Fiber optic cables used in external plants and premises, like distribution and patch cables, often have colored outer jackets or printing for easy identification. The EIA/TIA-598 standard defines color codes for different fibers, making it simple to recognize cables with a single fiber type based on color.

- Multimode 50/125 (OM2) – Orange

- Multimode 50/125 (OM3, OM4) – Aqua

- Multimode 50/125 (OM5) – Lime Green

- Multimode (OM1) – Orange

- Multimode (100/140) – Orange

- Single mode (OS1, OS1a, OS2) – Yellow

- Polarization maintaining single-mode – Blue

Note: the fiber color code varies for military applications:

- Multimode 50/125 (OM2) – Orange

- Multimode 50/125 (OM3, OM4) – undefined

- Multimode 50/125 (OM5) – undefined

- Multimode (OM1) – Slate

- Multimode (100/140) – Green

- Single mode (OS1, OS1a, OS2) – Yellow

- Polarization maintaining single-mode – undefined

However, if a premises cable contains multiple fiber types, the outer jacket should include a printed legend stating the number and types of fibers inside. This helps users quickly specify the fiber count and types. For instance, you might see something like ” 12 Fiber 8 x MM, 4 x SM” printed on the cable.

Inner Fiber Color Code

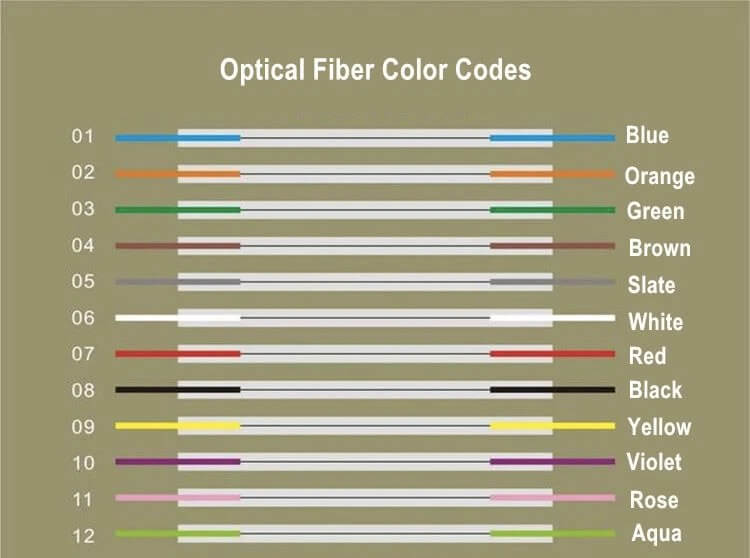

To facilitate easy identification, inner fibers in fiber optic cables are color-labeled. There are two common scenes based on the fiber number:

Cables with less than 12 strands of fibers use 12 different colors to identify each fiber individually.

Cables with over 12 strands of fibers, like 24 fibers, follow a color code sequence from 1 to 12, which then repeats. However, each 12-strand group is distinguished uniquely, such as by adding a stripe to the second group (in the case of a 24-strand cable) or using another distinctive mark to differentiate the new group.

- 1= Blue

- 2 = Orange

- 3 = Green

- 4 = Brown

- 5 = Slate

- 6 = White

- 7 = Red

- 8 = Black

- 9 = Yellow

- 10 = Violet

- 11 = Rose

- 12 = Aqua

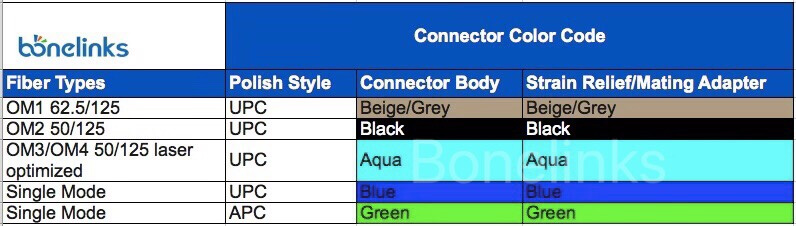

Connector Color Code

Fiber optic patch cords utilize color coding to identify connector types. Standard multimode OM1/OM2 cords come in beige or black, while OM3 and OM4 are aqua and magenta, respectively.

For single mode connectors, UPC terminations are blue, and APC terminations use green fiber connectors. It is crucial to distinguish between UPC and APC connectors since they cannot be mixed.

APC connectors (color-coded green) have fiber end faces polished at an 8-degree angle, while UPC connectors (color-coded blue) are polished with no angle, directing any reflected light toward the light source.

- 62.5/125 – Beige

- 50/125 – Black

- 50/125 Aqua

- OM5 – Lime

- Singlemode – Blue

- Singlemode APC – Green

Note: the same colors are also used for the strain relief/mating adaptor.

Conclusion

Fiber optic cable color coding is a valuable system that enables easy visual identification of different fiber types through colored jackets, connectors, etc. This system proves particularly useful for fiber optic engineers during splicing, ensuring continuity and facilitating efficient installation and maintenance. Fiber cable color coding plays a crucial role in enhancing communication and management in fiber optic networks. Its practicality and effectiveness make it an indispensable tool in the world of fiber optics.