According to the different production processes, there are currently two types of optical splitters: one is the fused biconical taper splitter (FBT) produced by the traditional taper coupler process, and the other is planar lightwave circuit splitter (PLC) based on optical integration technology. These two kinds of optical splitters have their own advantages, users can choose these two different types of light splitter according to their different occasions and needs.

In this article, we will briefly introduce the differences between FBT fiber optic splitters and PLC fiber optic splitters.

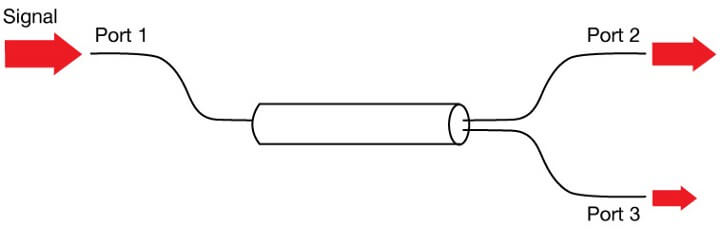

What is FBT splitter?

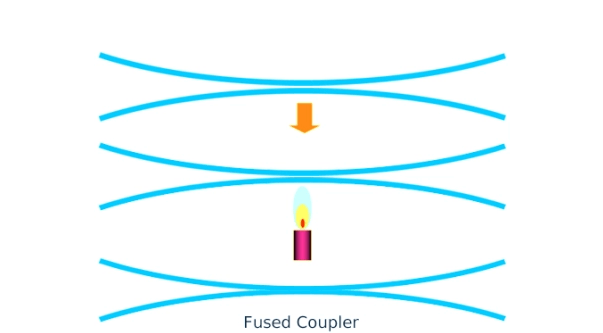

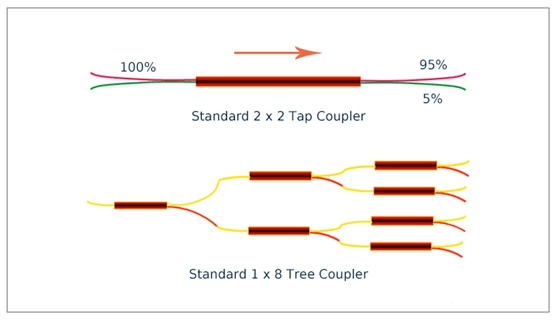

The fusion taper technology is to bundle two or more optical fibers together, and then melts and stretches them on the taper machine. During the stretching process, the coupling and splitting ratio of each fiber is monitored. One fiber (the rest is cut off) is used as the input end, and the other end is used as the multiplex output end. The series-connected fused cone 1×N shunt devices are all fused in series by (N-1) 1×2 taper units in a package box. Since the optical fibers between the units need to be spliced, and the optical fibers need to have a minimum bending radius, the volume is usually larger. For example, a 1×8 optical splitter is formed by splicing seven 1×2 units, and the package size is usually 100×80×9mm.

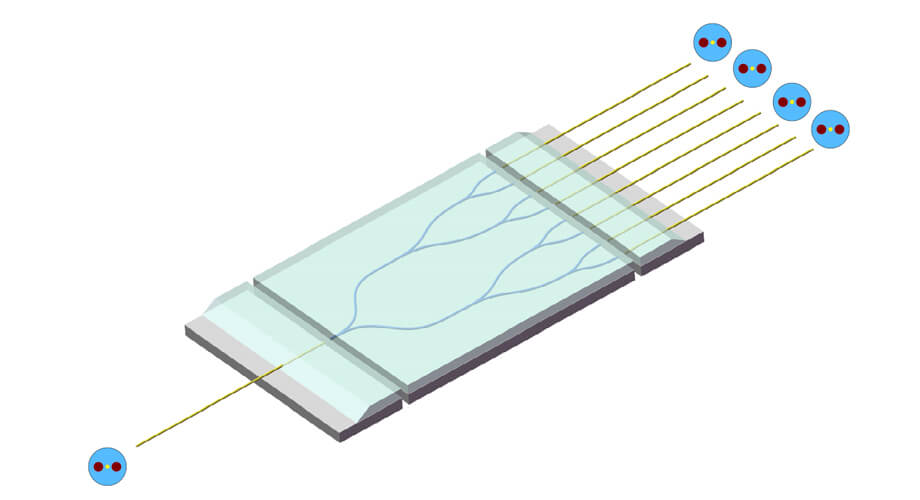

What is PLC splitter?

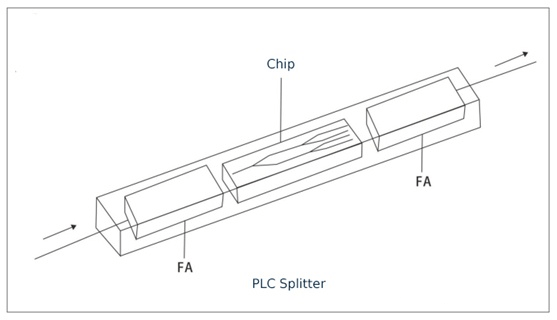

This device is composed of an optical splitter chip and an optical fiber array coupling at both ends. The chip uses semiconductor technology (photolithography, etching, development, etc.) to grow a layer of spectral waveguides on a quartz substrate. The chip has an input end and N output end waveguides. Then, the input and output fiber arrays are respectively coupled at both ends of the chip, and the casing is sealed to form an optical splitter with one input and N output fiber. Commonly used optical splitters are 1×N and 2×N (N=4, 8, 16, 32, 64).

It can be seen from the above that the production process of PLC optical splitter and FBT optical splitter is different. In addition, these two optical splitters also have the following differences.

FBT vs PLC fiber optic splitters: Differences in materials

FBT fiber splitters are made of steel, fiber optics, heat shrink tubing, and other common materials. PLC fiber optic splitter is mainly made of chips and fiber arrays.

FBT vs PLC fiber optic splitters: Differences in size

Since the FBT fiber splitter is packaged by multiple 1×2 connections, the package size will be large. The size of PLC fiber optic splitter is more compact than FBT fiber optic splitter. Therefore, PLC fiber splitters are more suitable for high-density applications.

FBT vs PLC fiber optic splitters: Differences in wavelength

PLC optical splitter is not sensitive to the working wavelength, that is to say, the insertion loss of light of different wavelengths is very close. Usually, the working wavelength reaches 1260-1650nm, covering all possible wavelengths required by various PON standards, as well as the waves required for various test monitoring equipment.

For FBT optical splitter, due to the change of fiber mode field generated by taper process, it is necessary to adjust the process monitoring working window, and the working wavelength can be adjusted to 1310nm, 1490nm, 1550nm and other working wavelengths as needed (commonly known as working window). Usually, single-window and dual-window device process control is more mature, and the three-window process is more complicated. In the case of poor process control, the insertion loss will change with the prolongation of operating time and the continuous change of temperature.

FBT vs PLC fiber optic splitters: Differences in asymmetric attenuation

The splitting ratio of the PLC splitter is determined by design and the spectral ratios of commonly used devices are equal. Due to the high uniformity of the semiconductor process, the uniformity of the device channel is good. PLC splitter can ensure that the volume of the output light is consistent.

The splitting ratio of the FBT splitter can be controlled on-site as required. If 1×N equal parts are required, then N-1 equal parts 1×2 are combined. Because it is impossible for each 1×2 device to be completely equally divided, the final output light inhomogeneity of each channel of the 1×N devices connected in series is amplified by the product.

It is found by experiments that the loss of each channel of PLC changes very little with the wavelength, and the equality of the channel is also good; the loss of the FBT splitter changes greatly with the change of wavelength, only the loss near the window wavelength is small.

FBT vs PLC fiber optic splitters: Differences in splitting ratio

The splitting ratio refers to the ratio of the input optical signal to the output optical signal of the optical splitter. The splitting ratio of PLC optical splitter is as high as 1:64, while the splitting ratio of FBT optical splitter is 1:32. PLC optical splitter can provide higher reliability. However, the optical division ratio of FBT optical splitter is variable and supports customization, such as 1:3, 1:7, and 1:11, while PLC optical splitter can only choose 1:2, 1:4, 1:8, 1:16, 1:32, and 1:64 standard products.

The variable splitting ratio of the FBT splitter is the biggest advantage of this device. Sometimes, due to the inconsistency of the number and distance of users, it is necessary to distribute the optical power of different lines, and devices with different splitting ratios are required. Since the splitting ratio of PLC devices cannot be changed at any time, only FBT splitters can be used.

FBT vs PLC fiber optic splitters: Differences in failure rate

At present, the configuration of FBT splitter is less than 1×4 at a time. Therefore, when the splitting ratio is greater than 1:8, the FBT optical splitter needs more than 7 1×2 connection packages, which are prone to errors and failures. The greater the splitting ratio of the FBT optical splitter, the greater the failure rate. The failure rate of PLC optical splitter is much smaller than that of FBT optical splitter.

FBT vs PLC fiber optic splitters: Differences in TDL (Temperature Dependent Loss)

The operating temperature of the PLC optical splitter is -40~+85℃, and the change of insertion loss with temperature is small. FBT splitter usually works at -5~+75℃, and the change of insertion loss with temperature is large, especially at low temperatures.

FBT vs PLC fiber optic splitters: Differences in PDL (Polarisation Dependent Loss)

The PDL of the PLC optical splitter is very small. For PLC splitter below 1×32, it is usually 0.1 to 0.2 dB. The PDL of the 1×2 FBT optical splitter is about 0.15dB. As more devices are connected in series, the PDL will also be superimposed, and the PDL of the 1×8 FBT optical splitter is close to about 0.45dB.

FBT vs PLC fiber optic splitters: Differences in size

The device size of PLC is very small, and the device size of 1×32 PLC splitter is usually 50×7×4mm. Since the FBT splitter requires multiple devices to be spliced, and the minimum bending diameter of the optical fiber is required to be >30mm, the diameter of the 1×8 FBT splitter is usually 100×80×9mm.

FBT vs PLC fiber optic splitters: Differences in cost

The main cost of PLC splitter is equipment cost and material cost (chip and fiber array). The production equipment of this device is expensive, but it is a one-time investment. With the expansion of the production scale, the larger the output and the more channels, the lower the average cost per channel.

The main cost of FBT splitter is labor cost and qualified rate cost. The cost of raw materials is very low (quartz substrate, optical fiber, heat shrinkable tube, stainless steel tube, etc.). The material cost of low-shunt devices is low, and the qualification rate of high-shunt devices is low.

According to the current production cost, PLC splitter compares with the three-window FBT splitter, 1×8 splitting is the critical point. Above 1×16 splitting, PLC splitter is more cost-effective, and as 1×4 or less splitting, FBT splitter is more cost-effective.

FBT vs PLC fiber optic splitters: Differences in reliability

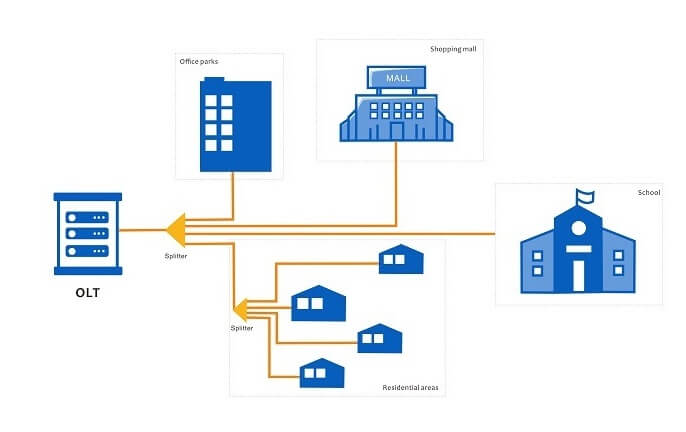

The biggest advantage of a passive optical network (PON) over an active optical network (AON) is that the passive optical network, except for the central office and the user end, all intermediate lines are passive devices, with good reliability and low operation and maintenance costs.

Due to a large number of nodes, the FBT splitter is prone to microscopic defects such as scratches during the fiber stretching process. Therefore, its resistance to mechanical shock and mechanical vibration is poor. It has poor reliability and high operation and maintenance costs.

With the rapid expansion of FTTH using PON technology, the amount of optical splitters has expanded rapidly, and the advantages of PLC optical splitters have been fully utilized. With the expansion of the output of PLC, the cost of PLC has also dropped rapidly, and its overall cost (material, labor, equipment, maintenance, management,etc) is obviously better than that of the FBT splitter.

FBT vs PLC Fiber Optic Splitters: How to choose?

These two types of optic splitters have their own advantages in terms of price, performance, etc, and both process technologies are constantly being upgraded to overcome their respective shortcomings. The FBT splitter is solving the problems of a small number of one-time configurations, the PLC splitter is also making efforts to reduce costs. Then, how to choose? It should be considered from the perspective of use occasions and user needs.

Use occasions: In some applications where volume and optical wavelength are not very sensitive, especially when there are few branches, it is more economical to choose an FBT optical splitter. For example, a 1310nm FBT splitter is used for independent data transmission, 1550nm FBT splitter can be selected for video network. PLC splitter should be selected in occasions where multiple wavelengths of optical transmission are required, such as FTTH.

User requirements: If it is only single-wavelength transmission or dual-wavelength transmission, FBT devices can be selected from the perspective of cost. If it is broadband transmission of PON technology, considering the need for future expansion and monitoring, PLC devices are preferred.

In addition to FBT and PLC splitters, which are divided according to different production processes, there are other splitters by different classifications. Click here to know more about fiber optic splitter types.

Summary

The above are the differences between FBT fiber optic splitter and PLC fiber optic splitter. Hope it is useful and can help you choose a suitable fiber optic splitter. Bonelinks is optical splitter supplier, providing both FBT fiber optic splitter and PLC fiber optic splitter. Contact us if needed.