Fiber optic cables offer superior performance compared to copper cables, including higher speed, higher bandwidth.Also, they can cover longer distances without signal degradation. There are various fiber optic cable types, each with unique benefits. Due to the rise of optical communication, more and more optical cable products have entered the market. So, what are the common types of fiber cable? Understanding these options will help you choose the right fiber optic cables for your networking project.

1. Fiber Optic Cable Types by Transmission Performance, Distance, and Use

It can be divided into long-distance optical cable, local optical cable, submarine optical cable, and user optical cable.

| Fiber cable types | Structure | Performance requirements | Application |

| User optical cable | Unitube, ribbon | High density, wide bandwidth, low/medium loss. | Computer network, FTTH (fiber-to-the-home) |

| Local optical cable | Unitube, Ribbon, stranded loose tube | Low loss, wide bandwidth | Within the city |

| Long-distance optical cable | Intercity, long distance | ||

| Submarine optical cable | Stranded loose tube | Low loss, wide bandwidth, high mechanical performance, high reliability | Underwater |

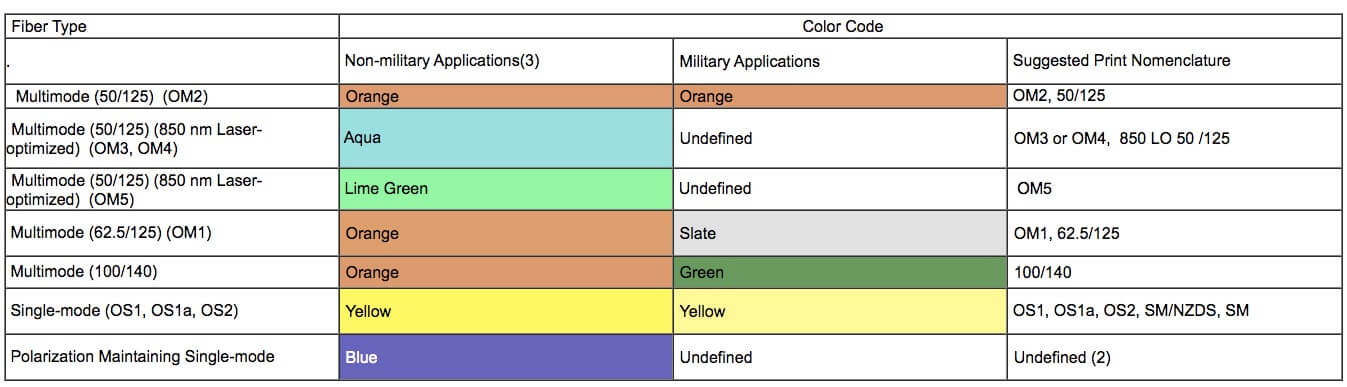

2. Type of Fiber Optic by Light Transmission Mode

It can be divided into single mode and multimode fiber. Single-mode fiber cable can be classified into 9/125 OS1 OS2 fiber. Multi-mode fiber cable can be classified into 62.5/125 OM1 fiber, 50/125 Laser-Optimization OM2, OM3, OM4, OM5 fiber.

In General, Single Mode (SM) fiber is used for long distances or higher bandwidth needs and uses a laser has its light source while Multimode (MM) Fiber uses an LED as its light source and is used for short distances or less bandwidth intensive applications.

Since OM1 and OM2 fiber could not support the higher speeds, OM3 and OM4 became the main choice for multimode fiber to support 25G, 40G and 100G Ethernet. With even greater demands on the horizon, OM5 was developed to extend the benefits of multimode fiber in data centers.

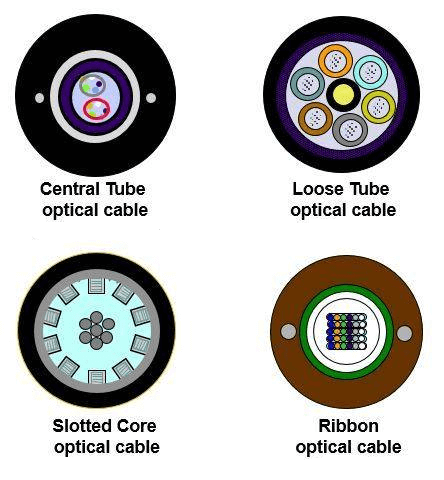

3. Fiber Optic Cable Type by Structure

It can be divided into stranded loose tube cable, slotted core fiber cable, unitube cable, and ribbon cable.

| Structure | Structural features | Performance characteristics | Laying method |

| Stranded loose tube cable

| Optical fibers are twisted around a central strength member | The fiber is easy to manufacture, has good mechanical and environmental performance, and small fiber count | Direct burial, pipeline, overhead, and underwater laying |

| Slotted core fiber cable | Fiber is placed in the slotted core | The optical fiber is complicated to manufacture, has good protection performance, good pressure measurement strength, compact structure, small cable diameter, and large fibers counts | Pipeline laying |

| Unitube cable

| Fiber is placed in the center tube | The structure is simple, the manufacturing process is the simplest, the cost is low, and the fibers count is flexible, but the fibers count in the cable should not be too much | Overhead laying |

| Ribbon cable

| Fiber is placed in a ribbon fiber unit in a tube or slotted core | The most space-efficient fiber optic cable that can accommodate a large number of fibers | Direct burial and pipeline laying |

4. Type of Fiber Optic by Fiber Core Count

It can be divided into 1-core fiber optic cable, 2-core fiber optic cable, 4-core fiber optic cable, 6-core fiber optic cable, 8-core fiber optic cable, 12-core fiber optic cable and 24-core fiber optic cable, etc. The optical fiber count is mainly related to the device interface connected by the optical fiber and the communication mode of the device. Generally speaking, the number of optical cores in the optical fiber is the total number of device interfaces multiplied by 2, plus 10% to 20% of the spare number. If the communication method of the device includes serial communication and device multiplexing, the number of cores can be reduced.

5. Fiber Optic Cable Type by Laying Method

It can be divided into pipeline optical cables, direct buried optical cables, overhead optical cables, and underwater optical cables.

The main difference between pipeline optical cables, direct buried optical cables, overhead optical cables, and underwater optical cables is the laying method, and the performance of the optical cable is different correspondingly.

- Overhead optical cable: Overhead optical cable is an optical cable used for hanging on poles. The overhead optical cable laying method can use the original overhead open line pole road, save construction costs and shorten the construction period. Aerial optical cables are required to be able to adapt to various natural environments, and are suitable for areas with flat terrain and fewer undulations.

- Directly buried optical cable: When laying directly buried in the ground, the requirements for lateral pressure are relatively strict. This optical cable has steel tape or steel wire armor on the outside, and is directly buried in the ground, which requires the performance of resisting external mechanical damage and preventing soil corrosion performance.

- Pipeline optical cable: It is laid in the pipeline, commonly used for outdoor optical cable in the access network or customer premises network. Pipe laying is generally in urban areas, there is no special requirement for the jacket of the optical cable, and no armoring is required. Before pipe laying, the length of the laying section and the position of the connection point must be selected.

- Underwater optical cable: It is laid on the seabed, generally used to establish telecommunication or power transmission between countries or regions. Submarine optical cables are laid in extremely complex marine environments. It has multiple layers of armor and is required to have excellent tensile strength, water pressure resistance, corrosion resistance, resistance to hydrogen loss, and other properties.

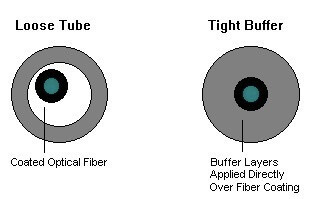

6. Type of Fiber Optic by the Configuration

Fiber optic cables come in two construction styles – loose tube and tight buffered. Both have strengthening members like aramid yarn or stainless steel wire strands. In tight buffered cables, there’s no gap between fiber cores’ coating and cladding layers, while loose tube cables have a gap filled with gel or are loose.

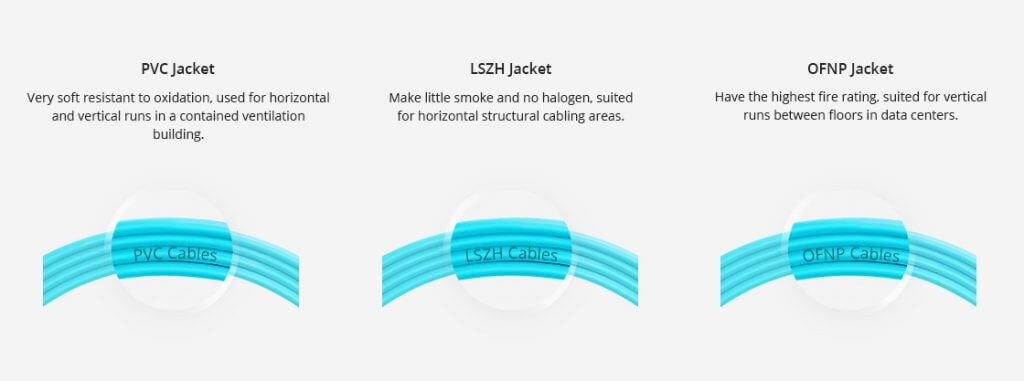

7. Fiber Optic Cable Type by the Properties of the Outer Jacket Material

Fiber optic cables can be divided into PE polyethylene jacket ordinary optical cables, PVC jacket flame retardant optical cables and nylon anti-rodent-optical cables, etc.

| Jacket Material | Benefits of Jacket Material |

| PE (Polyethylene) | PE has excellent properties of moisture and weather resistance, and has good electrical properties over a wide temperature range. It’s also abrasion resistant. So PE is the standard outer jacket material for outdoor fiber optic cables. |

| PVC (Polyvinyl Chloride ) | PVC is usually low-cost, flexible, fairly rugged, and a flame/oil-resistant material, so it can be formulated to function in a variety of environments and applications. In other words, it can be used as the outer jacket material for both indoor and outdoor cables. |

| PVDF (Polyvinyl Difluoride) | PVDF is used for plenum cables because it has better fire-retardant properties than PE and produces little smoke. |

| LSZH (Low Smoke Zero Halogen) | LSZH jacket is free of halogenated materials which can be transformed into toxic and corrosive matte during combustion. LSZH materials are used to make a special cable called LSZH cable, which is a good choice for inner installations. But it is the most expensive outer jacket material. |

| Plenum | It is one of the main components to form OFNFP-grade optical fiber cables. It has high flame retardancy and does not generate toxic or corrosive gases at extremely high temperatures. Fiber optic cables with Plenum materials are the first choice for wiring in air return pressurization systems used in ventilation ducts or air handling equipment. |

| Riser | It is one of the main components of the OFN-grade optical fiber cable. The flame retardant performance is weaker than that of the Plenum material. At the same time, it has no toxic gas and corrosive gas. Therefore, the OFNR grade optical fiber cable with riser material is usually used in building trunk lines and horizontal cables. |

8. Type of Fiber Optic by Transmission Conductor and Medium Condition

Fiber optical cables can be divided into metal-free optical cables, ordinary optical cables, and integrated optical cables. Metal-free optical cables are mainly used in areas with strong electromagnetic influence and frequent lightning, and integrated optical cables are mainly used in railway dedicated network communication lines.

9. Fiber Optic Cable Type by Optical Fiber

Glass Optical Fiber (GOF) and Plastic Optical Fiber (POF) are two types of optical fiber used in telecommunications networks to transmit light signals through thin wires. POF is more resistant than GOF, as glass is a sensitive and less resistant material compared to plastic. Hence, POF is more suitable for corrugated tubes and domestic installations where breakage risk is higher.

10. Type of Fiber Optic by Use Environment

It can be divided into outdoor optical cable, indoor optical cable, submarine optical cable, etc.

- Outdoor optical cable: It is used for outdoor direct burial, pipeline, channel, tunnel, overhead and underwater laying. The outer packaging is thick and has some mechanical and environmental characteristics such as pressure resistance, corrosion resistance and tensile strength.

- Flexible fiber optic cable: A removable fiber optic cable with excellent flexural properties. It has small outer diameter, good flexibility, is easy to bend, is suitable for indoor or small space occasions, and is often used in optical connectors, FTTH, sensing and other fields.

- Indoor optical cable: It is suitable for indoor deployment. Indoor optical cable has good bending resistance, fire resistance and flame retardant, strong flexibility, suitable for communication equipment in buildings with short transmission distances.

- Submarine optical cable: It is for transoceanic laying. No need to dig tunnels or support with brackets, submarine optical cable has characteristics of low investment, and fast construction. Also, it performs little interference from the natural environment and human activities, has good confidentiality, security, and stability, and are mostly used for long-distance international transmission.

- Special optical cables: In addition to the above categories, there are optical cables for special purposes, such as hybrid cables, tactical optical cables, anti-rodent optical cables, etc.

11. Fiber Optic Cable Type by Emerging Optical Cables

The emergence of new optical cable materials has also promoted the improvement of optical cable structure, such as the use of dry water blocking materials, nanomaterials, flame retardant materials, etc., which have significantly improved the performance of optical cables. In recent years, emerging optical cables such as ecological optical cables, nanotechnology optical cables, and micro-optical cables have emerged.

- Ecological optical cable: It is mainly from the perspective of environmental protection, to solve the problem of non-environmentally friendly materials in optical cables, such as PVC burning will release toxic gases, and lead in optical cable stabilizers. Ecological optical cables are mainly used indoors, buildings and homes. At present, some companies have produced new materials for ecological optical cables, such as halogen-free flame-retardant plastics.

- Nanotechnology optical cables: Nanotechnology optical cables use nanomaterials, such as nanofiber coatings, nanofiber ointments, polyethylene for nanosheathing, nano-PBT for optical fiber sheathing, etc., utilizing many excellent properties of nanomaterials, such as improving mechanical shock resistance of optical cables.

- Micro optical cable: The micro optical cable is mainly used to cooperate with the installation and construction system of air pressure or water pressure. Various micro optical cable structures have been designed and used. There is a certain coefficient between the optical cable and the pipe. The weight of the optical cable should be accurate and have a certain hardness. In order to meet the needs of the future access network, the micro-optical cable and automatic installation method are specially integrated into the wiring system in the customer premises network and wiring in the intelligent pipeline of the intelligent building.

Summary

Bonelinks is OEM/ODM fiber cables products and solutions supplier, dedicated to providing customers with reliable and quality optic products. We provide different types of fiber cable, which are widely used in FTTH fiber-to-the-home, 4G/5G mobile communications, data centers, high-density communications and other fields. If you cannot find a product that you need or if you are looking for something special, contact us as we might already have the solution.