As we see high bandwidth demands double that of fiber optics, ribbon cable becomes the simplest, easiest and fastest way to plan for current and future network needs. It offers higher fiber count, higher fiber density, and high bandwidth than any other cable construction designed for outside plant (OSP), 4 times that of the highest fiber count loose tube cable. Let’s learn more about ribbon cables.

What is Ribbon Fiber Cable?

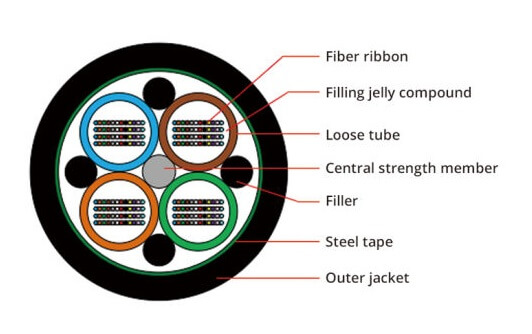

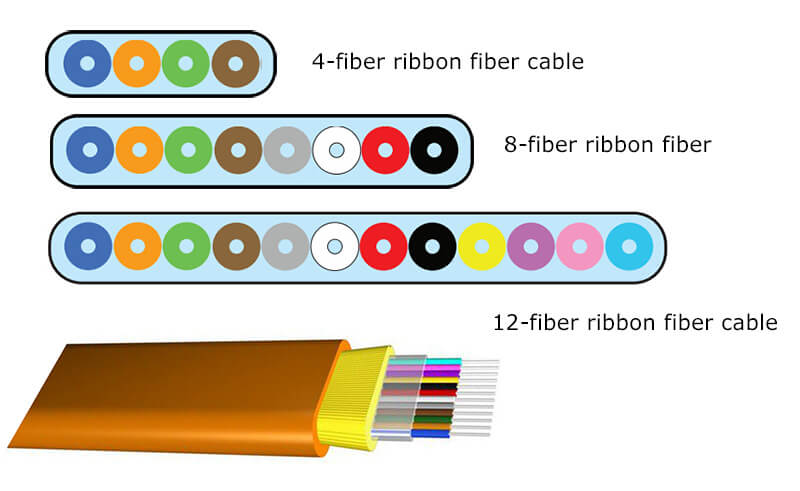

Ribbon fiber optic cable gets its name from the ribbon-like structure formed by bonding a series of separate fibers in a flat strip. This technology allows up to 24 fibers to be grouped together, placed side by side to create a compact ribbon. Special waterproof tape secures the ribbon in place, utilizing coated fiber to save space during network work. It’s a popular choice for applications with limited installation space, such as data centers, as ribbon cables facilitate easier fusion splicing, leading to time and cost savings.

Ribbon fiber optical cables are standardized by international bodies like IEC and ICEA, with designations in the IEC 60794 series specifications and some ICEA fiber cable files. These cables are also mentioned in Telcordia Technology’s specifications for external plant fiber and fiber optic cables.

Advantage of Ribbon Fiber Cable

Cost and Time Savings in Installation

Ribbon fiber cables are pre-banded, containing multiple sets of separate fibers. Installers can perform quick and efficient mass fusion splicing, connecting all fibers in the ribbon matrix simultaneously. This reduces installation time, lowers labor costs, and allows for faster recovery during downtime.

Increased Fiber Density for Space-Efficiency

Ribbon fiber cables offer higher fiber packing density than individual fiber cables. This is beneficial in scenarios requiring more fibers within limited duct space. Higher fiber counts result in improved network uptime, increased revenue, and enhanced customer satisfaction.

Cost-Effective Fiber Solutions Compared to Ordinary Fiber Cable

Ribbon fiber optic cable offers cost advantages over ordinary fiber cable in two key aspects:

- Fiber Optic Cable Price: Although the production processes for optical fiber ribbons and cables are slightly more complex, the unit prices are becoming more competitive due to increased usage of ribbon fiber optic cable and market dynamics.

- Optical Splicing Cost: The high splicing efficiency of ribbon fiber optic cable results in lower splicing costs per joint. This advantage becomes more significant with higher fiber counts in the ribbon fiber.

Overall, using ribbon fiber optic cable in the optical communication network is a slightly more economical choice than ordinary optical cable.

Space-Efficient Ribbon Fiber Optic Cables

Ribbon fiber’s lighter, more compact design allows for a smaller footprint in telecom rooms and splice closures, making it easier to handle than cables with individual fibers.

Disadvantages of Ribbon Fiber Cable

Large Splice Loss in Ribbon Fiber

Due to limited bending options, ribbon fiber splicing may result in higher attenuation compared to single-core splicing. Priority bending along the longitudinal axis can cause stress on fibers, damaging the cable and leading to insertion loss.

Larger Diameter for Small Fiber Count

For fiber optic cables with less than 144 cores, the ribbon fiber optic cable has a larger outer diameter compared to ordinary optical fiber cables.

Ribbon Fiber Applications

- Ribbon fiber optic cable is commonly used in indoor/outdoor point-to-point networks and indoor FTTH networks.

- It is also utilized for interconnection and cross-application of MTP fiber wiring boxes.

- Additionally, ribbon fiber cables are often installed in urban construction for circle trunk cable networks.

Difference between Ribbon Fiber and Loose Tube Fiber Cable

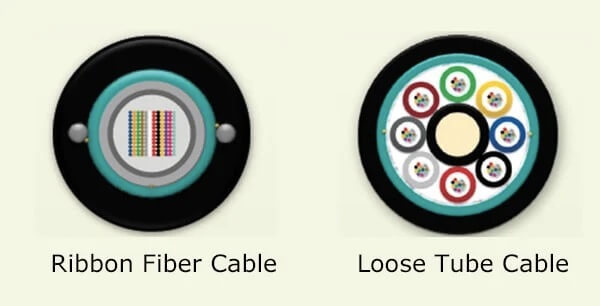

Ribbon fiber cables have a flat ribbon-like appearance, while loose tube fiber cables have a round bundle of optical cables.

Structure: Ribbon fiber cables consist of a fiber band, while loose tube fiber cables are usually composed of a 0.9mm loose casing.

Optical fiber arrangement: In ribbon fiber cables, the fibers are arranged in color order, banded, and fixed, while in loose tube fiber cables, each fiber is more independent and not arranged.

FAQs about Ribbon Fiber Cable

Q: How many fibers are in a ribbon?

A: Ribbon fiber cables can contain 4, 8, 12, or 24 optical fibers in each ribbon. This high fiber density allows for efficient mass fusion splicing, making it easy to manage, install, and restore the cables.

Q: How do you splice ribbon fiber to loose tube?

A: Splicing a ribbon fiber to a loose tube cable requires a different approach. The ribbon fiber is first stripped down into individual fibers at the splice cassette. Then, a single fiber splicer is used to create a connection to the loose tube fiber cable, one fiber at a time.

Q: Can a single fiber splicer be used for ribbon fiber cable splicing?

A: Yes, but it is time-consuming and not recommended. The process is explained in the previous answer.

Q: What is rollable ribbon fiber?

A: Rollable ribbon fiber is an innovative optical fiber cable containing 12 partially bonded ribbon fibers. It doubles fiber density and finds applications in front haul, fiber to the home, and mobility network backhaul.

Q: How do you make fiber ribbons?

A: Fiber ribbons are formed by aligning multiple optical fibers in a single row and impregnating them with an acrylate UV curable resin. The ribbons are then stacked to form a bundle inside a central core tube or stranded multi-tubes.

Summary

The ribbon cable is lightweight, compact, and easy to handle and splice. It’s ideal for future expansion as transmission protocols advance to higher data rates. They are ideal for future expansions as data rates increase. Bonelinks provides various ribbon fiber cables for indoor fiber cabling.