1. What is hybrid fiber cable?

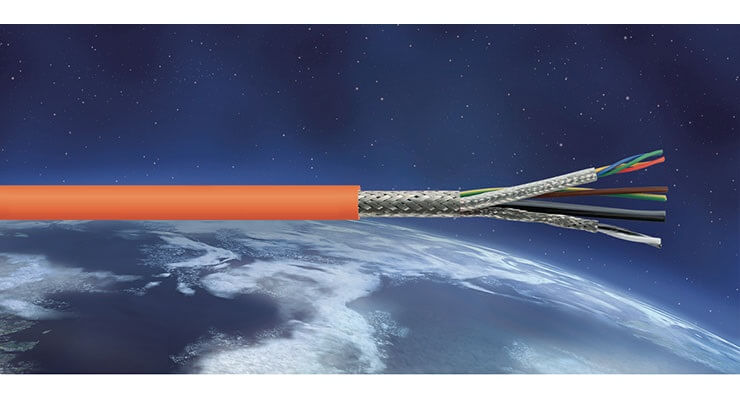

Hybrid fiber cable is a new type of access method that is suitable for transmission lines in broadband access network systems. It integrates optical fibers and copper wires for power transmission, and can solve the problems of broadband access, equipment power consumption, and signal transmission.

2. Development of hybrid fiber cable

The normal operation of network services generally requires equipment to solve two problems through cables: the power supply of the equipment itself and the transmission of data. However, the installation environment of some devices is relatively complex, such as WLAN APs, 5G small cells, video surveillance cameras, etc. It is difficult to have suitable power sockets around the installation environment, making it difficult to supply power to the devices. In such scenarios, it often requires solving the problems of device power supply and data transmission at the same time through a single cable.

Communication cable, according to the different media, can be divided into optical cable with optical fiber as the transmission medium and copper cable with copper wire as the transmission medium.

Optical fiber uses the principle of total reflection of light for data transmission, which has the advantages of large bandwidth, low loss, and long transmission distance. However, the material of optical fiber is glass fiber, which is an electrical insulator and cannot support PoE power supply.

Copper wire uses metal as a transmission medium and uses the electromagnetic wave principle for data transmission, which can transmit data signals and power signals, but there will be thermal effects in the transmission process, so the loss is large, and it is not suitable for long-distance data transmission. In the network integrated wiring specification, it is clearly required that the total length of the twisted pair link cannot exceed 100 meters.

So how to solve this problem? Hybrid fiber cable integrates optical fiber and copper wire into one cable, uses optical fiber to transmit data signal, and uses copper wire to transmit power signal, which can not only complete high-speed data transmission, but also complete long-distance equipment power supply.

According to the difference in interface types, hybrid fiber cable has undergone the evolution of the first generation and the second generation. The interface of the first generation is separated from optical and electrical, and the connection to the device needs to occupy an optical port and an electrical port respectively. The interface of the second generation is integrated with optoelectronics, and only one optoelectronic hybrid interface is required to connect to the device.

3. Types of hybrid fiber cable

According to the actual use, hybrid fiber cable can be divided into pipeline hybrid fiber cable, overhead hybrid fiber cable, direct buried hybrid fiber cable, indoor wiring hybrid fiber cable, special-purpose hybrid fiber cable, and others. The number of fiber cores is generally 2-144 cores, and the cable voltage range is from 48V-110kV.

General pipeline type, overhead type, direct buried type, and indoor wiring type hybrid fiber cables are mainly used outdoors, which can provide power transmission and signal transmission for communication outdoor macro stations. The indoor wiring hybrid fiber cable is mainly used indoors to provide power transmission and signal transmission for the communication indoor distribution station.

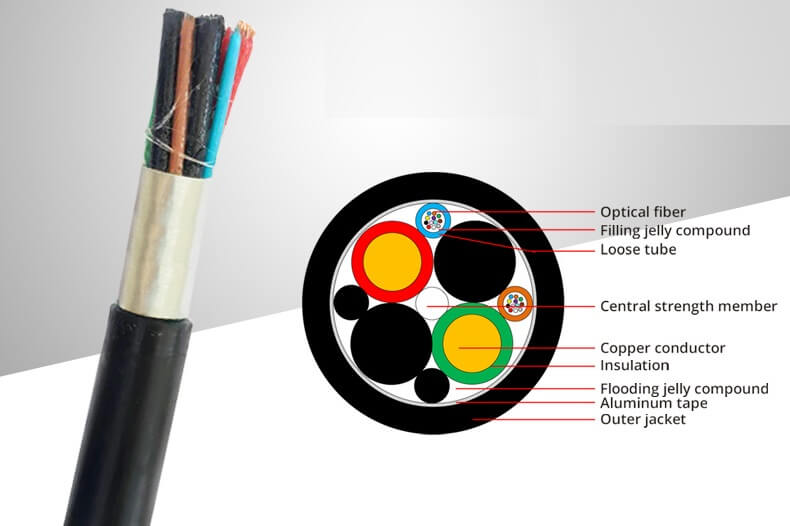

4. Hybrid fiber cable structure

Hybrid fiber cable is mainly made of optical fiber and copper wire.

Hybrid fiber cables are available in a variety of constructions, including multimode or singlemode fiber. They can include single-fiber or multi-fiber, depending on the application and the number of devices connected. For example, optical network terminations (ONTs) used in passive optical networks operate on a single fiber to transmit signals simultaneously in both directions using wavelength division multiplexing (WDM) technology, where upstream data is 1310nm and downstream data is 1490nm.

The number and type of copper conductors used for power supply in hybrid cables also vary, depending on the number of devices connected and power supply requirements. For example, some hybrid cables may contain up to 12 copper conductors to connect to remote power devices, or only two conductors to connect to a single device.

Copper wires are also typically between 12 and 20 AWG, which directly affects how much power they can carry over a given length, with larger wires able to carry more power over longer distances. For example, hybrid fiber cables with 12 AWG conductors can deliver 75W up to 457m (1500 feet), while 20 AWG conductors can only deliver 75W up to 71m (235 feet). Therefore, wire size is a key factor when choosing a hybrid copper cable.

Conductor: The conductor of the hybrid fiber cable should be copper wire that has undergone annealing process, and the single wire is not tinned.

Cable insulation: The commonly used insulation materials are polyvinyl chloride and polyethylene insulation. Because the composite cable has high requirements on various properties of the insulation material, hybrid fiber cable should be made of irradiation cross-linked polyene. The insulating material has excellent properties such as good heat resistance, insolubility, non-melting, non-combustion, high mechanical strength, heat-resistant deformation, and good crack resistance.

Optical: There are various structures of optical units, such as aluminum tubes, stainless steel tubes, aluminum frames and sleeves. The optic unit inside the high-temperature photoelectric composite control cable should adopt the non-metal loose sleeve structure in sleeve molding. The optical unit is in the inner layer, and this structure not only protects the optical unit, but also ensures the extra length of the optical fiber. At the same time, a layer of outer sheath is extruded after the cable is formed, which plays the role of waterproof, moisture-proof and impurity-proof for cable.

5. Advantages and disadvantages of hybrid fiber cables

5.1 Advantages of hybrid fiber cables

- Small outer diameter, lightweight

- It has excellent bending resistance and good lateral pressure resistance, convenient construction and maintenance, and is conducive to the long-term stable operation of the network

- Provide high-bandwidth access and solve the problem of equipment power consumption during network construction (avoid duplication of power supply lines)

- The equipment has high adaptability and scalability, and the product is widely applicable

- The use of hybrid fiber cable to supply power to remote devices is convenient for construction and reduces construction costs

- The line is safe and reliable, waterproof and moisture-proof. Cable length can be customized without connectors

- The centralized power supply from the computer room ensures that the remote monitoring equipment can still operate normally under the condition of external power failure

5.2 Disadvantages of hybrid fiber cables

- Hybrid fiber cables may not be suitable for laying in weak current pipelines, and the construction specifications need to be further clarified

- The hybrid cable is live, and attention should be paid to the danger of electric shock for construction and maintenance

- If they are used in the same way as ordinary optical-fiber

6. Applications of hybrid fiber cables

Forecast data from GSMA shows that by 2025, 1.3 billion people in the world will use 5G, 5G network coverage will reach 40%, and the number of 5G mobile terminal connections will reach 1.4 billion. On the other hand, statistics show that more than 967 million households have access to broadband in the world, and 286 operators in 49 countries have released gigabit broadband services. The emergence of innovative home businesses such as smart homes will also promote the construction of new business forms centered on the home.

It is foreseeable that in the near future, our network will be the “dual Gigabit” era of “5G + fiber fixed network”. But there are two “blind” needs in network coverage:

- Inadequate coverage of individual regional networks (eg remote rural areas), which may not have adequate electricity supply;

- Under the requirements of the new generation network, the coverage density of network equipment will be greatly increased (for example, the density of 5G small base stations will be significantly higher than that of 4G), and the problem of power supply at the newly added points of this equipment may cause problems for equipment deployment.

The above two demand points bring new demands to the wiring system, and the hybrid cable provides a more reasonable solution to meet such application scenarios. It meets the requirements of higher and higher requirements for speed, stricter requirements for network reliability, and full network coverage.

Under the new networking situation, hybrid fiber cables can be used in many fields.

6.1 The application of POL all-optical network for hybrid fiber cables

POL (Passive Optical LAN) passive all-optical network is a new campus network solution emerging in recent years. Single-mode optical fiber is used as the medium, and PON technology, which has long been widely used in the fiber-to-the-home broadband access market of telecom operators is technically adopted. In addition to breaking through the transmission distance limitation of traditional Ethernet, thanks to the passive optical splitting characteristics of PON technology, POL can also save active equipment at the aggregation layer compared to traditional Ethernet switch solutions, as well as the resulting equipment room space, a series of expenses such as power distribution and cooling.

The biggest feature of the POL all-optical network is that the network equipment ONU and OLT are placed at the equipment side and the core computer room respectively. There is no active equipment between the ONU and the OLT, the transmission distance is long, and the ONU active equipment points are scattered. If we use the traditional method, the data optical cable and the power supply copper cable are laid separately, and the material cost, construction cost, management and maintenance cost will be much higher than the integrated hybrid fiber cables. POL all-optical network to realize the true indoor all-optical network, even if only short-distance copper cable jumpers are used at the end of the equipment, the synchronous arming of the indoor ONU data optical cable and power supply copper cable must be considered, and the cable and power supply, routing design and implementation must be simplified, and hybrid fiber cable and its management system will be the best choice. At present, hybrid fiber cables have been widely used in public security, wireless communication, patrol, and vehicle management systems in the park.

6.2 The application of smart light pole for hybrid fiber cables

Smart light pole is a public infrastructure that integrates various functions, which can provide functional lighting, traffic monitoring, pollutant monitoring, air quality monitoring, Wi-Fi, 4G/5G base station, broadcasting, information screen, charging pile, etc. In current network infrastructure construction, it has received more and more attention.

In the construction of smart light poles, a large number of devices are integrated into the light pole, and each device needs at least 1-2 cables for power supply and signal transmission, and the space of the light pole is small. Therefore, the reduction of the outer diameter of the cable and the integration of the cable bundle are the two new requirements for the cable industry in the field of smart light pole construction. The cables for power supply and signal transmission for smart light poles involve power lines, network cables, and optical cables. At this time, how to provide a reasonably designed hybrid fiber cable will become a new opportunity for this industry.

6.3 The application of industrial park monitoring system for hybrid fiber cables

The industrial park monitoring system is composed of five major parts: camera, transmission, control, display, and record registration. The camera transmits the video image to the control host through the optical fiber, and the control host distributes the video signal to each monitor and video recording device, and simultaneously records the voice signal to be transmitted into the video recorder. If the traditional wiring method is used, it will face problems such as long transmission distance, wide distribution of active equipment points, tight routing and difficult construction and maintenance. The excellent characteristics of hybrid fiber cables make them widely used in industrial park monitoring systems.

6.4 The application of 5G small base station coverage for hybrid fiber cables

With the continuous increase of 5G business and the continuous expansion of industry boundaries, the industry predicts that more mobile services will occur indoors in the future. 5G applications such as high-definition video, AR/VR, telemedicine, industrial manufacturing automation, and modern logistics management occur in indoor scenarios of buildings and require higher bandwidth to carry. In order to obtain more bandwidth, indoor 5G introduces higher frequency bands (C-Band and millimeter wave), which means greater transmission and penetration loss, as well as denser networking. High-density small base station construction will inevitably be 5G indoor scene.

At the same time, the massive amount of active network equipment in the 5G era will bring new challenges to operation and maintenance and energy management of the system, and the problem of power supply for a large number of small base station equipment will be a problem that network construction units must solve. The hybrid cable integrates the optical unit and the electrical unit at the same time, which can provide signal transmission for the small base station equipment and power supply for the small base station equipment. It is one of the mainstream solutions to solve the coverage problem of 5G small base stations.

6.5 The application of DC remote supply scheme for hybrid fiber cables

With the implementation of strategies such as 4G/5G, communication optical cables and equipment continue to extend to the user side, and the power supply of equipment such as remote base stations, communication equipment rooms, and user access points has become a difficult problem, especially in individual remote areas. The hybrid cable DC remote supply solution is conducive to the centralized construction, operation and maintenance of power equipment in the network. It can realize the common cable transmission of high-efficiency power and optical signals at the same time, with low construction cost and high operation and maintenance efficiency.

The common practice of high-voltage DC remote power supply systems is: the power supply is composed of central office and remote equipment. It is transmitted to the remote device through hybrid cable, and the voltage is inverted through the remote device to convert to the voltage required by the remote device (such as DC48V or AC220V), which is the load (RRU, fiber repeater, small macro base station, micro-cellular base station, ONU and other equipment) to provide maintenance-free power supply. In this application scenario, the conventional cable type is shown below.

6.6 The application of FTTA (Fiber To The Antenna) for hybrid fiber cables

During the 4G/5G construction period, a large number of antenna devices (Active Antenna Unit, AAU for short) need to be installed on the tower. To achieve this, each AAU needs to install one cable + one optical cable (2 cores). From the perspective of base station construction, each base station requires three AAU devices (that is, three sectors), and 2/3/4/5G networks are likely to need to coexist. If several operators are added to network construction, each tower may require dozens of optical cables and dozens of cables to be installed on the tower at the same time, which brings several problems to the system installation: 1) The material cost of multiple cables; 2) Dense cable arrangement on the tower; 3) Multiple installations on the tower.

Therefore, in the construction of remote optical cables, many people propose pre-terminated FTTA cabling solutions, and adopt the method of “trunk remote optical cable on the tower + installation of junction box branches on the tower + branch remote optical cable to each AAU equipment”. It can effectively increase the flexibility of construction. It can play certain cost and construction advantages in 5G construction.

6.7 The application of high-density wiring for hybrid fiber cables

For the support platform for information applications, large and super-large data centers are increasing day by day, and the requirements for information storage and processing capabilities are getting higher and higher. As the infrastructure of data center informatization, the integrated wiring system is an important part of the network operation of the data center system. Faced with a large number of cables, how to operate and manage effectively has attracted more and more attention. In order to solve this problem, people have introduced different forms of cable search solutions, among which hybrid cable is constantly playing its role in this field.

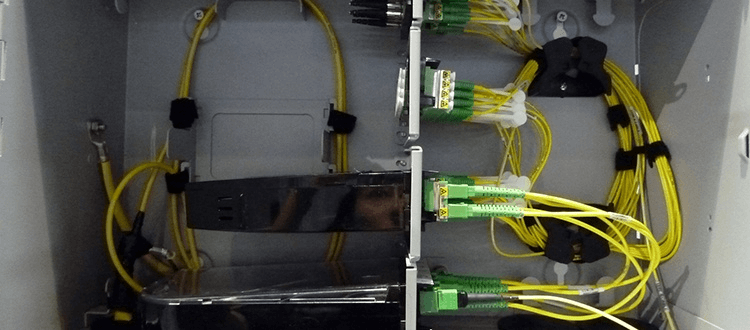

In order to realize the management and control of the optical fiber port, the electronic patch panel system can be used. The intelligent optical fiber patch cord is composed of a traditional optical patch cord + 1-2 copper wires. The port of the patch panel integrates LED lights, and the port information is collected through intelligent optical fiber. The copper wire in the jumper and the LED light line is connected and disconnected to judge the link status, thereby indicating the port status.

In terms of network cable tracing, in addition to implanting copper wires and using LEDs for port indication, there is an alternative solution for hybrid cables. That is to say, the plastic optical fiber is integrated into the network cable, illuminated by an external visible light source, and the corresponding cable status is indicated at the other end of the cable.

6.8 The application of consumer electronics for hybrid fiber cables

With the advancement of FTTH/5G, the application bandwidth will get a further leap, and high-definition video conferencing/AR/VR/telemedicine/8K video will gradually enter people’s daily life, and these high-bandwidth experiences, traditional copper cables It will be difficult to meet the application requirements, especially the application distance requirements of copper cables, which will further limit the further application of traditional copper cables in the field of consumer electronics. Therefore, the use of optical fibers for data transmission will be one of the mainstream directions for the development of consumer electronics cables.

Based on the requirements of application scenarios, equipment power supply also puts forward certain demands on cables, and hybrid cables integrate optical fibers and power cables, which can effectively solve application requirements, and only need to lay one cable to solve communication and power supply problems at the same time. It provides a more reasonable choice for consumer electronics applications. The more commonly used connector interfaces are USB3.0/HDMI, etc.

The application of optoelectronic technology in real life is also more and more extensive, which has a significant impact on people’s production and life. However, the means of transmitting electrical energy and the means of transmitting light are different methods. When transmitted separately, the two types of energy will not interfere. The hybrid fiber cables integrate power supply and signal transmission. It can effectively solve the problems of broadband access, equipment power consumption, and signal transmission, and at the same time, it can save space and cost, and improve transmission efficiency. It is a very ideal optical fiber access method.

7. Precautions for construction and installation of hybrid fiber cables

When using optical-electrical hybrid fiber cables, the following items should be paid attention to:

- When using optoelectronic hybrid fiber cables, it should meet the design and construction specifications of power cables and communication optical cables at the same time:

- The connection in the hybrid cable line should be avoided as much as possible. The line within 3KM is prohibited from being connected. When connecting, a special joint box for the hybrid cable must be used, and waterproof treatment must be done;

- When hybrid fiber cables is terminated, a special termination device should be used;

- The hybrid fiber cables lines should be routed separately as far as possible, and protected by PVC pipes;

- During the construction process, it is necessary to ensure the integrity of the outer sheath of the hybrid fiber cables. After the construction is completed, the hybrid fiber cables needs to be tested for the insulation performance of the transmission wire to the ground, to the armor, and the metal reinforcement core;

- The lines should be regularly inspected by personnel with power maintenance qualifications and communication maintenance qualifications;

- When the fault is repaired, the power should be cut off for maintenance, and the line conductor should be grounded first, and then the maintenance operation should be carried out.

8. Summary

The network demand for cabling systems is further diversified, and applications such as 4G/5G base stations, WiFi equipment, security equipment, traffic monitoring equipment, and climate detection systems in enterprise parks are gradually increasing. The hybrid fiber cables integrate optical fiber, power line and other functions to realize the integration of communication and power supply, and will play an increasingly important role.

Bonelinks is hybrid fiber cable manufacturer. Our hybrid fiber optic cable realizes optoelectronic integration, solves the problem of equipment power consumption and signal transmission, and can be widely used in telecommunication network construction, communication base station, mobile base station construction, FTTH fiber to the home in urban residential communities and buildings, and other applications that require information and power at the same time, etc. We can also produce hybrid fiber cable with different wire specifications and quantities according to user requirements, and hybrid fiber cable with different fiber cores according to customer requirements. If necessary, please contact us.