Optical fibers are fragile. When used in various environments, it must be processed into optical cables with corresponding mechanical properties to ensure that the optical fibers are not damaged by external forces during the process of laying, installation, use, and maintenance, so as to ensure the smooth flow of the network. Based on this, people have developed and designed armored fiber optic cables.

1. What is armored fiber optic cable?

Armored fiber optic cable is a kind of fiber cable wrapped with a layer of protective “armor”. Its armor is mainly used to protect the fiber optic cable from animal bites, moisture erosion, or other damage.

2. Why use armored fiber optic cable?

In the past, outdoor optical cables were usually laid in solid pipes to prevent the cables from being damaged by external forces. However, this fiber optic cable laying method is very complicated, and it will take a lot of time and labor costs. Therefore, some people design to add a layer of metal armor to protect the core of the optical cable, which is also known as armored optical cable. Armored optical cable has the functions of strong compression and tensile resistance, which can effectively adapt to harsh outdoor environments, and the wiring is much more flexible than pipe wiring. Now, armored optical cables have been widely used in the field of optical communication.

3. Structure of armored fiber optic cable

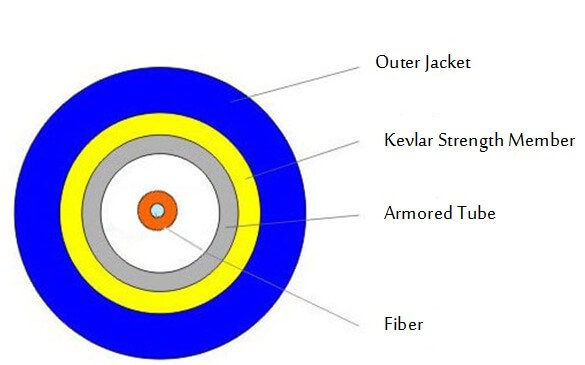

- Outer jacket: In the design of the armored optical cable, the outer sheath can protect the cable from solvent and abrasion damage, usually the outer sleeve is made of plastic, such as polyethylene.

- Metal armor: between the outer sheath and the inner sheath is the armor, which is difficult to cut, bite and burn, such as steel tape and aluminum foil, and can also prevent the cable from stretching during the laying process. The metal armor is located between the inner sheath and the outer sheath, and there is also a layer of aramid yarn between the outer sheath and the metal armor.

- Ripcord(optional): Usually the sheath stripping rope is directly under the armor and inner sheath, which can help to strip the sheath when splicing the optical cable to the connector or terminal.

- Inner sheath: It is a protective and flame-retardant material that can support the inner cable harness. Internal cable harnesses include strength members, fillers, and other structures to support the cables internally. Typically there is a central strength element supporting the entire cable.

Simply speaking, in armored fiber optic cables, the buffer conduit is surrounded by a layer of aramid yarn, a polyethylene jacket, and a corrugated steel plate armor. There is also a type that with a ripcord.

4. Armored fiber optic cable type

4.1 Armored fiber optic cable by applications

Armored optical cables can be divided into indoor armored fiber optic cable and outdoor armored fiber optic cable according to the application.

- Indoor armored fiber optic cable

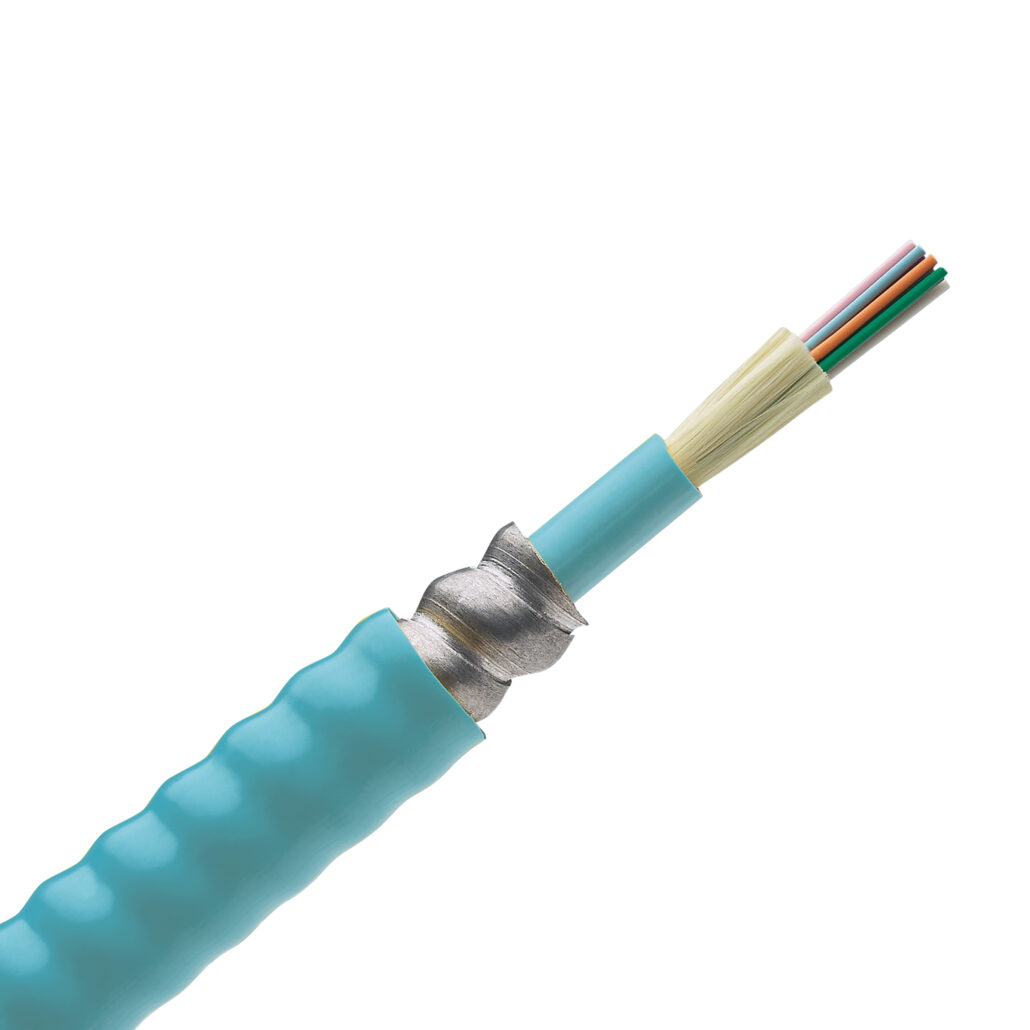

Armored cables for indoor use typically consist of either tight or loose buffered fibers with strength members and an inner jacket, which is usually surrounded by a helically wound interlocking metal armor. Indoor armored optical cables include single-layer armored and double-armored optical cables. Single armor refers to the fiber optic cable without stainless steel braid. Double armor refers to the fiber optic cable with stainless steel hose and stainless steel braided wire. Among them, double-layer armored optical cables are often used in extreme environments such as near-shore shallow seas, while single-layer armored optical cables are used in other occasions outside these extreme environments. With the rapid development of optical fiber communication technology and the trend of FTTX applications, the demand for indoor armored fiber optic cable is growing rapidly.

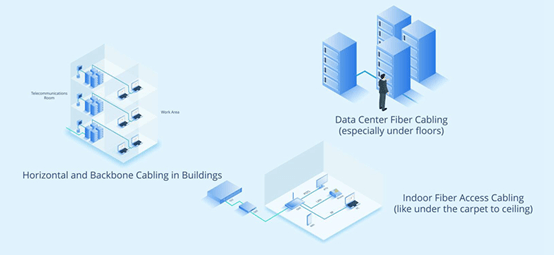

The following figure shows several application scenarios of indoor armored fiber optic cable:

- Outdoor armored fiber optic cable

Armored optical cables for outdoor use are designed to ensure safe operation in complex outdoor environments, most of which are loose-tube optical fiber structures. Outdoor armored cable can be divided into light armored cable and heavy armored cable. The light armor has steel and aluminum tape, and the heavy armor is covered with a circle of steel wire. Lightweight armored cable offers the same durability and service life as stainless steel cable with a protective plastic jacket, but at a lighter weight for most applications in industrial and semi-harsh environments for added protection and rodent resistance. The heavy-duty armored optical cable is wrapped with a ring of steel wire, which can protect the optical fiber from animal eating and damage caused by direct burial installation. It is suitable for riverbeds and seabeds, and has strong waterproof function. Generally, the price of light armored fiber optic cable is cheaper than that of heavy armored fiber optic cable.

4.2 Armored fiber optic cable by metal armor type

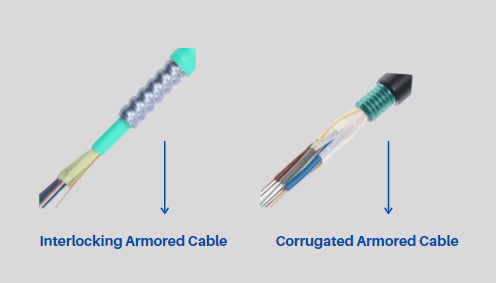

Armored optical cables can also be divided into interlocking armored optical cables and corrugated armored optical cables according to the type of metal armor.

Interlocking armored fiber optic cables are aluminum helically wrapped around the fiber optic cable, commonly used in indoor and outdoor applications, with high durability and excellent crush resistance. Corrugated armored cable is a coated steel tape that is folded longitudinally around the cable and is often used in outdoor applications, providing superior mechanical properties and resistance to rodent bites.

Both types of armored fiber optic cables can be used in harsh outdoor environments such as excessive dust and rodent bite damage.

4.3 Armored fiber optic cable by usage

Directly buried armored cable is used to protect the cable wrapping and steel tape armor is used. Vertically laid armored cables are generally armored with thin steel wires to withstand general longitudinal tension.

Outdoor overhead armored optical cables have two types: one is the central bundle type; the other is the standard type. In order to be durable, the aerial armored optical cable adopts an extra layer of sheath. The main purpose is to avoid harsh environments, human or animal damage and to protect the fiber core.

4.4 Armored fiber optic cable by laying environments

According to different laying environments, armored optical cables can be divided into tight-buffered armored cable and loose-buffered armored cable. Tight-buffered armored cable can be used in indoor applications and indoor/outdoor applications, the structure is optical fiber and a tight jacket layer (usually PVC) on the surface to form a tight jacket fiber. Loose armored cable is usually used in outdoor applications, and the main structural type is multiple optical fibers, which are filled in the casing in a free state. In order to protect the optical fibers and play a role in blocking water, fiber paste should be filled. The structure is multiple optical fibers, fiber paste and loose tube layer (PBT). In the field of outdoor applications, the armored fiber optic cable used in it is designed with loose tube structure, which can be directly buried in the ground.

5. Key features of armored fiber optic cables

- high tensile strength

- High compressive strength against undue twisting

- Simple structure to prevent bending damage

- Save maintenance costs

- Suitable for harsh environments and can prevent human damage

6. The main application of armored fiber optic cables

Armored fiber optic cables are mainly used in directly buried exterior equipment applications where robust cables are required and need to be resistant to gnawing by rodents and other animals. The excellent crush resistance of this cable is necessary for direct buried applications. For direct burial fiber optic cables used in areas where rodents are more harmful, usually there is a metal armor between the two layers of sheaths, which can prevent rodents from biting through the sheathes.

Another application area of armored fiber optic cables is in data centers, where the fiber optic cable is installed below the ground, so it may be crushed due to the extrusion of the floor. Because the armored fiber optic cable is conductive, it must be well grounded in an appropriate way.

7. Summary

In the field of optical fiber communication, any optical fiber failure may cause significant loss of financial and material resources, so protecting the optical fiber is the top priority in the installation process of the optical fiber communication system. Armored fiber optic cables not only have the characteristics of ordinary optical cables, but also provide additional protection for optical fibers, making them more robust, reliable and durable. Bonelinks is armored cable manufacturer, if you have any needs, please contact us, and we would provide you with the most suitable armored fiber optic cables.