With the further improvement of people’s living needs, the Internet has become an important part of life. In order to adapt to the development of the information age, the integrated wiring technology and products are constantly updated, especially the large-scale research and development of optical fiber cables.

1. How to Choose Fiber Optic Cable?

There are many different types of optical fiber cables with different uses on the market. Then, how to choose the most suitable fiber optic cable? Here are some important questions to ask before selecting fiber optic cable.

1.1 Distance and Network Speed

Generally speaking, if you require that the transmission distance of optical fiber is relatively short, such as several hundred meters, then multi-mode fiber can be used. However, if the transmission distance is several kilometers or even longer, then single-mode fiber must be used without signal relay.

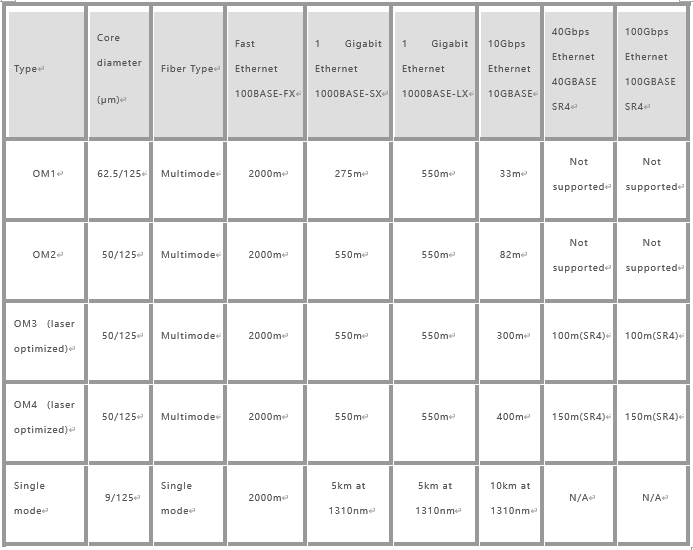

OM stands for optical multi-mode. It is a standard for multimode fibers to express fiber grades. The bandwidth and maximum distance of different levels of transmission are different.

- OM1 refers to 50um or 62.5um core diameter multimode fiber with 850/1300nm full injection bandwidth above 200/500MHz.km;

- OM2 refers to 50um or 62.5um core diameter multimode fiber with 850/1300nm full injection bandwidth above 500/500MHz.km;

- OM3 is a 50um core diameter multimode fiber optimized by 850nm laser. In 10Gb/s Ethernet using 850nm VCSEL, the fiber transmission distance can reach 300m;

- OM4 is an upgraded version of OM3 multimode fiber, and the fiber transmission distance can reach 550m.

1.2 Transfer Tasks

4 cores, 6 cores, 8 cores, or more? To complete the transmission task, the optical fiber must have at least two cores, one for receiving and one for transmitting. In fact, there are 4 cores, 6 cores, 8 cores, or even more core optical fibers on the market, and the extra cores can be used for backup or more transmission channels.

1.3 Cable Jacket

Cable jacket material plays a very important role in the long-term reliability of the optical cable, and is the key to determining the characteristics of the fiber optical cable, including the tensile, flattening, bending, temperature, resistance to natural aging (irradiation, chemical corrosion) as well as the fatigue. Therefore, high-density polyethylene material (PE) should be selected. It has high hardness, good tensile and compressive properties, and the outer skin is not easy to be damaged.

PBT is a thermoplastic engineering plastic for making secondary plastic (bundle) of optical cables. It has high (1600/mm2) Young’s modulus, low wire tension coefficient (1.5 × 10-4), good chemical resistance, low friction coefficient, good processing characteristics and so on.

PBT material is used as the fiber optic sleeve, so that the fiber optic bundle tube unit has good resistance to lateral pressure and temperature characteristics. In order to ensure the long life of the optical cable, hydrolysis-resistant PBT materials must be used in places with high requirements for hydrolysis resistance.

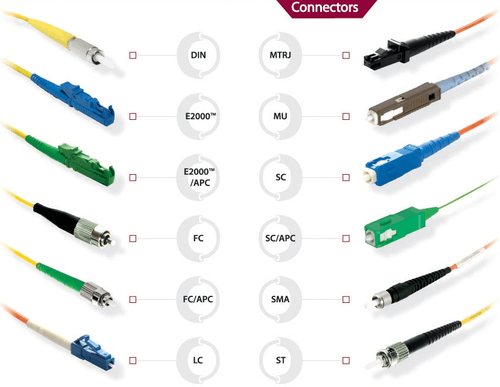

1.4 Connectors

What are FC, SC, ST, LC, and MTRJ, and which connectors should be used? These different connectors are used in different environments. There is no unified standard. The difference between them is mainly reflected in the connection method and shape. Is it tightened like a screw or directly attached? Is it square or round? Is it a large port or a small port (large port takes up more space, small port can have greater port density)? Are the two heads separate or integrated? You do not need to care too much about the specific interface. It should be noted that if the expansion is carried out when the old optical fiber system already exists, it must be matched with each other.

When it comes to connectors, we should understand two terms, return loss and insertion loss. Generally speaking, for single-mode fiber patch cords, RL≤0.3dB, IL≥60dB (regular data); for high requirements, RL≤0.2dB, IL≥65; for multimode fiber patch cords, RL≤0.5.

1.4.1 What is Return Loss?

When a fiber optic signal enters or leaves an optical component (such as a fiber optic connector), discontinuities and impedance mismatches will cause reflection or return, and the power loss of the reflected or returned signal is the return loss ( referred to as RL). Insertion loss mainly measures the resulting signal value when the optical link encounters loss, while return loss is the measurement of the reflected signal loss value when the optical link encounters component access.

Calculation formula: RL=-10 lg (P0/P1), P0 represents the reflected optical power, and P1 represents the input optical power.

Return loss values are expressed in dB and are usually negative, so higher values are better, and typical specifications range from -15db to -60dB. According to industry standards, the return loss of Ultra PC polished fiber optic connectors should be greater than 50dB, and the return loss of bevel polish is usually greater than 60dB. PC type should be greater than 40dB. For multimode fiber, typical RL values are between 20db and 40dB.

Connector type | FC, SC, LC, ST, MU | |||

Mode | SM | MM | ||

Fiber end face | PC | UPC | APC | PC |

IL(db) | ≤0.3 | ≤0.2 | ≤0.3 | ≤0.3 |

RL(db) | ≥45 | ≥50 | ≥60 | ≥35 |

Connector type | MPO | |||

IL(db) | ≤0.7 |

| ≤0.7 | ≤0.5 |

RL(db) | ≥30 |

| ≥50 | ≥25 |

1.4.2 What is Insertion Loss?

Insertion loss (IL) refers to the measure of the light lost between two fixed points in the fiber. It can be understood as the loss of optical power caused by the intervention of optical devices in the optical fiber link of the optical communication system, and the unit is dB.

Calculation formula: IL=-10lg (Pout /Pin). Pout is the output optical power, and Pin is the input optical power.

The smaller the insertion loss value, the better the performance. For example, the insertion loss of 0.3dB is better than 0.5dB. In general, the difference in attenuation (less than 0.1 dB) between fusion and manual connections will be less than connections between fiber optic connectors.

Recommended maximum dB loss for fiber optic cabling in data centers: Maximum 15dB for LC multimode fiber connectors, 15dB maximum for LC single mode connectors, 20dB maximum for MPO/MTP multimode fiber connectors, and 30dB minimum for MPO/MTP single mode fiber connectors.

1.5 Switch

How is the fiber connected to the switch? Generally speaking, there are two ways, one is to connect the optical port integrated into the switch or the inserted optical fiber module through the optical fiber cord, the other is optical fiber transceiver. Connect the optical fiber cord to the optical port of the transceiver, and then use ordinary twisted pair cord that can be connected to the RJ45 port of the switch.

A wall-mounted fiber box or a rack-mounted fiber distribution frame? Wall-mounted optical fiber boxes are generally used in small optical fiber networks, such as a 4-core optical fiber, but if the number of optical fibers is relatively large, the rack-mounted distribution frame has its advantages. It can be placed in the same cabinet as the switch router, which is convenient for centralized management and safer.

1.6 Application Scenarios

According to different uses, the corresponding optical cables can be divided into aerial optical cables, pipeline optical cables, direct buried optical cables, submarine optical cables and metal-free optical cables. The aerial optical cable requires high strength and small temperature difference coefficient. The pipeline optical cable and submarine optical cable must be resistant to water pressure, tension and waterproof. The metal optical cable can be erected together with the high-voltage line, and the insulation is better. Although there is no iron reinforced core, it must have a certain tensile strength. Therefore, when purchasing an optical cable, users should choose according to the purpose of the optical cable, and put forward requirements to the manufacturer to ensure that the optical cable is stable and reliable.

Optical cables used in buildings should pay attention to their flame retardant, toxic and smoke characteristics when selecting them. Generally, the flame-retardant but smoke-free type (Plenum) can be used in the pipeline or forced ventilation, and the flame-retardant, non-toxic and smoke-free type (Riser) should be used in the exposed environment.

When laying cables vertically in the building, layer-stranded optical cables can be used; when wiring horizontally, branched optical cables can be selected.

When the outdoor optical cable is directly buried, the armored optical cable should be selected. When overhead, an optical cable with a black plastic outer sheath with two or more reinforcing units can be used.

1.7 Performance

The fiber attenuation value is normal within -28db, the lower the better. The fiber attenuation coefficient is one of the most important characteristic parameters of multimode fiber and single mode fiber, which determines the relay distance of multimode and single mode fiber communication to a large extent.

The attenuation coefficient is defined as the attenuation value of optical signal power per kilometer of fiber. Its expression is a= 10 lg Pi/Po. The unit is dB/km. Pi is the input optical power value (watts), Po is the output optical power value (watts).

There are many reasons for optical fiber attenuation, mainly including absorption attenuation (impurity absorption and intrinsic absorption); scattering attenuation (linear scattering, nonlinear scattering and structural incomplete scattering); other attenuation (microbending attenuation, etc).

Attenuation of an optical fiber is the reduction in optical power between two cross-sections of an optical fiber, and is wavelength-dependent. The main causes of attenuation are scattering, absorption, and optical losses due to connectors and splices.

The fiber attenuation coefficient is defined by the attenuation (dB/km) per unit length of a uniform fiber in steady state.

1.8 Length

How long of each reel and how many reels do you need?

One reel can be up to 16,000 feet. Before buying an optical cable, it is best to figure out how long the optical cable you need. We can get the result through measurement, and buy a certain length of optical cable that exceeds the measurement result.

The above are just a few issues that are considered from the application and other aspects, and need to be flexibly mastered during implementation. In fact, the wiring environment is complex and diverse, and various problems may appear at any time. This requires us to strictly follow the wiring standards during planning and construction. If problems are encountered, they will be satisfactorily solved by flexible analysis.

2. Fiber Optic Cable Basics

Optical cables are not only complex in structure, but also in a wide variety of materials. In addition to the existing technical parameters, there are many potential factors (materials, production processes, equipment, etc.). The technical parameters may not meet the standard after years. Therefore, when we are building a network, it is necessary to have an in-depth understanding of the structure, materials, and technology of the optical cable, so as to choose an optical cable with a suitable model and excellent quality.

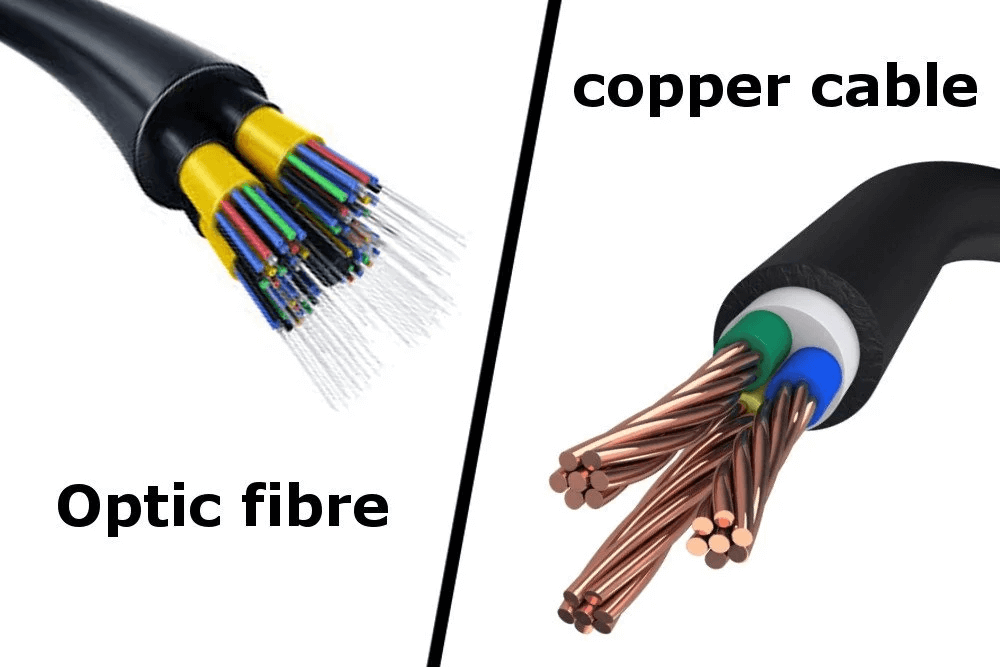

2.1 Fiber optic VS copper cable

With the continuous improvement of bandwidth requirements in the network era, there is a saying that optical fibers have gradually replaced traditional copper cables and become the mainstream of the 5G era. Will copper cables really be replaced by optical cables? Let’s talk about some knowledge about copper cables and optical cables.

Advantages of copper cables:

Although in the case of data center’s demand for higher bandwidth, optical fiber has the advantages of higher transmission rate, larger bandwidth, and longer transmission distance, so it occupies a larger share in data center deployment, especially in some important application network. But in fact, copper cables will still be an indispensable part of data centers, and in applications in special environments such as voice transmission and power supply, copper cables are cables that cannot be replaced by optical fibers.

In network transmission within 100 meters, optical fiber is inferior to copper cable in terms of maintenance, cost, and wiring. The fiber core in the optical fiber is a glass fiber, which is more fragile than the copper in the copper cable. In the wiring and later maintenance, the optical fiber will be damaged if not careful, and the copper cable is not easy to be damaged. In general, the wiring and maintenance of copper cables are more convenient and cost-effective.

In the transmission of voice signals, optical fibers cannot replace copper cables. Because copper cables are different from optical fibers in that they transmit data through electrical pulses, they can transmit voice signals, but optical fibers cannot.

Since the core of the optical fiber is made of silica, it cannot conduct electricity, while the copper in the copper core can conduct electricity. The copper cable can supply power while connecting data, and can be used in power systems.

Advantages of fiber optic cables:

- Light weight and small size: Compared with copper cable, the core diameter of optical cable is much smaller, and the weight of optical cables is much lighter than that of copper cable.

- Strong anti-interference: The optical cable only transmits optical signals, not electrical signals, and is not subject to electromagnetic interference, so the signals transmitted in the optical fiber are not easy to have eavesdropping attack, and the confidentiality is strong.

- Long transmission distance: Compared with copper cable, the longest distance of electrical signal transmission is 100 meters, and the transmission distance of optical cable is more than 100 kilometers.

- Abundant resources: The main raw material of optical cable is silica, that is, quartz, which is abundant in nature.

2.2 Compare the Different Types of Optical Fiber Cable

- According to different applications: Optical cables are divided into indoor optical cables, outdoor optical cables, branch optical cables, and distribution optical cables.

- According to the laying method: Optical cables are divided into aerial optical cable, pipeline optical cable, armored buried optical cable and submarine optical cable.

- According to the optical fiber structure: Optical cables are divided into bundled optical cable, layered optical cable, skeleton optical cable, hugging optical cable, ribbon optical cable, non-metallic optical cable, and branchable optical cable.

- According to the purpose: Optical cables are divided into long-distance communication optical cables, short-distance outdoor optical cables, hybrid optical cables and optical cables for building.

- According to the transmission mode: Optical fibers can be divided into single-mode and multi-mode optical fibers.

2.2.1 Multimode and Single Mode

Single-mode fiber: Fiber that transmits only one mode of optical signal, conventionally classified as G.652D, G.653, G.654, G.655, G657A and other transmission grades. The single-mode fiber that transmits 100M signals can reach a distance of up to dozens of kilometers. Single-mode fiber only transmits the main mode, that is to say, the light is transmitted only along the inner core of the fiber. Since mode scattering is completely avoided, the transmission frequency band of single-mode fiber is very wide, so it is suitable for large-capacity, long-distance fiber-optic communication, the light wavelength used by single-mode fiber is 1310nm or 1550nm.

Multimode fiber: Multimode fiber can transmit multiple modes of optical signals. According to optical mode, it is divided into OM1 (50/125um), OM2 (62.5/125um), OM3 (62.5/125um), OM4 (62.5/125um). The longest transmission distance of 100M signal is 2 kilometers. Multimode fiber, under a certain working wavelength, there are multiple modes transmitted in the fiber, and this kind of fiber is called multimode fiber. Due to dispersion or aberration, the transmission performance of this fiber is poor, the frequency band is relatively narrow, and the transmission capacity is smaller and has a shorter distance.

How to identify whether the fiber optic cable is multimode or single mode?

First of all, there is a relatively simple method. For indoor fiber optic cable, it can be identified by the external color. Single mode fiber optic cable is yellow, while multimode fiber optic cable is orange (OM1, OM2), aqua (OM3), rose red (OM4). Fiber patch cords are the same identification method. For outdoor fiber optic cable, it can generally be identified by the model code. There is a string of characters on the outer skin of the optical cable, such as GYXTW-4-A1a. The last segment starting with A means multi-mode fiber, and the one starting with B means single-mode fiber. In more detail, A1a stands for 50/125 multimode fiber, A1b stands for 62.5/125 multimode fiber, B1.1 stands for non-dispersion-shifted single-mode fiber, and so on. If it is not possible to identify whether it is a single-mode fiber or a multi-mode fiber in this way, it can only be identified by professional equipment, such as a fiber fusion splicer, which will automatically identify whether it is single-mode or multi-mode. The single-mode will display SM, multimode will show MM.

Of course, on the other hand, the core diameter of multimode fiber is generally 50μm or 62.5μm, while the single-mode fiber is generally only 8.3μm. From this point of view, the difference is relatively large, but it is still difficult to identify with the eye.

Remarks: μm is the code of micron, 1μm=1/1000mm

2.2.2 Simplex vs. Duplex

The number of cores is the number of glass fibers contained in each fiber. Here are some methods for determining the number of fiber cores.

First of all, clearly know the number of wiring points in this layer, calculate the number of switches, and whether the connections between switches are stacked or not. If the stack is stacked and the core switch is dual-machine hot standby redundancy, 6 cores are enough. If you do not stack a switch to 4 cores, multiply the number of switches by 4 plus the redundancy of 4 cores, and it will be enough.

Remarks:

Redundancy: as long as there are more than the ones used, the extra ones are called redundant master and backup. One is used, and the other is exactly the same as backup;

Hot backup: both are in a working state at the same time;

Cold backup: the backup device is in standby mode.

Experience: In the wiring room (horizontal wiring cabinet) on each floor, there is one optical fiber, generally six cores: two cores for use, two for backup, two for redundancy; there are also eight-core optical fibers. The specification’s minimum configuration is 2 cores per 48 points. Of course, 4 cores can be selected for 48 points, because 2 cores are the smallest unit of optical fiber, it is more appropriate to leave 2 more cores as backup.

The above is an introduction to the method of determining the number of fiber cores. The backup can be selected according to different persons, so the number of optical fiber cores needed varies greatly.

2.2.3 Jackets

According to the use environment of the optical cable, different protective jackets are added outside the cable core to better protect the optical fiber; including metal tape (steel tape, aluminum tape) longitudinal wrap, inner sheath and outer sheath. As a protective layer for optical cables to resist various special and complex external environments, the jacket must have excellent mechanical properties, environmental properties and chemical properties. The jacket material is mainly MDPE (medium density polyethylene).

Comparison of different PE jackets materials

- LDPE: low-density polyethylene, good flexibility, and extensibility;

- HDPE: high-density polyethylene, good rigidity, toughness, and high tensile strength, and large modulus, good wear resistance;

- LLDPE: Linear low-density polyethylene, the performance is between LDPE and HDPE, with both the flexibility of LDPE and the excellent tensile strength of HDPE;

- MDPE: medium density polyethylene, good resistance to environmental stress cracking, rigidity, heat resistance, and low-temperature resistance, but high melt viscosity and poor processing performance.

- Halogen-free flame retardant jacket material: Halogen-free flame retardant jacket material is a non-toxic and smokeless clean flame retardant material. When burning in fire, the inorganic flame retardants Al(OH) and Mg(OH) that are added to the jacket material will release crystal water, absorb a lot of heat, and inhibit the temperature rise of the burning jacket material, thereby preventing burning.

2.2.4 Connectors

According to the structure:

- FC: The shape is cylindrical, the diameter of the ferrule is φ2.5mm, and it is fixed on the adapter by the thread;

- SC: The shape is rectangular, the diameter of the ferrule is φ2.5mm, and the plug-in connection is easy to operate;

- ST: The shape is cylindrical, and the diameter of the ferrule is φ2.5mm bayonet connection;

- LC: Miniaturized rectangular structure, ferrule diameter φ1.2mm plug-in self-locking connection;

- MU: Miniaturized rectangular structure, ferrule diameter φ1.25mm plug-in connection;

- MT-RJ: Cuboid in shape, miniaturized dual-core, MT ferrule, one male and one female connection

According to the shape of the ferrule end face

- PC (Physical Contact): The end face of the ferrule is spherical, and RL is greater than 40dB;

- UPC (Ultra Physical Contact): The end face of the ferrule is also spherical, RL is greater than 50dB.

- APC(Angled Physical Contact): Inclined spherical surface, 8-degree angle. RL is greater than 60 dB

2.2.5 Stranded, Skeleton, Ribbon and Center Tubes

According to the number of cores, the structure of different types of optical cables can be divided into stranded, skeleton, ribbon and center tubes.

Generally, the central bundled tube type is used for 12 cores or less. The central bundled tube type has a simple process and low cost, and is competitive in the branch and trunk network with overhead laying or good pipeline protection.

The stranded cable is reinforced, and the SZ continuous synthetic cable is used, and the number of fibers in the cable can reach 144 cores. Its biggest advantage is waterproof, strong side pressure, and strong pull resistance. It can be used for direct burial. At the same time, it is easy to bifurcate, that is, when part of the optical cable needs to be used separately, it is not necessary to disconnect the entire optical fiber cable, but only the optical fiber to be bifurcated can be disconnected, which is very important for the data communication network. It is helpful to add optical nodes along the cable television network.

The number of cores of the ribbon optical cable can reach thousands of cores. It arranges 4 to 12 core optical fibers in a row to form a ribbon optical fiber unit, and then multiple ribbon units are arranged according to a certain amount.

2.2.6 Internal Construction of the Product

- Tight buffer:

Tight buffer is generally used for indoor optical cable. Its structure is optical fiber and a tight sleeve layer (usually PVC) on the surface to make a tight buffer fiber. - Breakout or Fan Out:

Breakout (fan out) fiber optic cable contains several jacketed simplex optical fibers packaged together in a jacket. This differs from distributed cables where tightly buffered fibers are bundled together and only the outer cable jacket of the cable protects them. Breakout cables are designed to increase the strength of the sturdy droplets, but are larger and more expensive than distribution cables. - Zipcord:

Zip-cord, also called patch cord, refers to two fiber optic lines that have their own jackets, and then the jackets of the two lines are sewn together. There is also a form in which a plurality of optical fibers with circular sheaths is coated with a circular sheath. - Loose Tube

Loose tubes are generally used for outdoor optical cables. A plurality of optical fibers is filled in the tube in a free state to protect the optical fibers and block water. The structure is multiple optical fibers + fiber paste + loose sleeve layer (PBT).

3. Summary

Whether you choose multimode, single-mode, indoor, or outdoor fiber optic cables, you can contact Bonelinks. Based on your application environment and needs, we will recommend the most cost-effective optical cable to save your costs and truly provide you with the best solution.