Fiber optic cables provide versatility and durability in a wide range of applications and are critical to ensuring high reliability, high speed, high bandwidth, high security, low latency and future-proofing. Fiber optic cable for outdoor use has a strong design, which can protect the optical fiber to operate stably in complex outdoor environments.

What is Fiber Optic Cable for Outdoor Use?

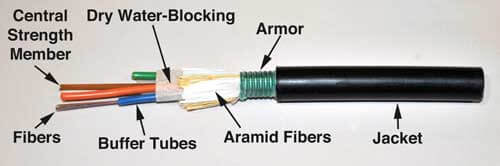

As the name suggested, fiber optic cable for outdoor use is the fiber optic cable used in outdoor applications. Fiber optic cables for outdoor use typically have thicker outer jackets, armor elements, and strength members designed to withstand rough handling, harsh weather, and harsh environments.

Features and Benefits

Fiber optic cable for outdoor use provides excellent attenuation performance over a wide temperature range, is protected from water ingress, has a robust structure to resist UV rays, and can withstand various mechanical forces, compression, corrosion, and tension. In addition, the outdoor optical cable has fast transmission speed, long distance, good confidentiality, anti-electromagnetic interference, good insulation, good chemical stability, long life and low loss.

Types of Outdoor Fiber Optic Cable

Depending on the application, fiber optic cables for outdoor use include aerial optical cables, direct buried optical cables and duct optical cables.

- Aerial fiber optic cable: Aerial fiber optic cable is suspended from a pole or tower or mounted on a building. Some are self-supporting and do not require separate slings between the poles to support the weight of the fiber optic cable.

- Direct burial fiber optic cables: In the absence of duct infrastructure, fiber optic cables can be buried directly in the ground in trenches or using vibratory plows.

- Duct cables: Ducts (or conduits) provide a highly protected environment for fiber optic cables. They are usually buried and then the fiber optic cable is blown, sprayed, pulled or pushed into the duct.

Fiber optic cables for outdoor use are divided into loose tube optical cables, ribbon optical cables, micro optical cables and drop optical cables according to the cable structure.

- Loose tube cables: Loose tube cables provide stable performance over a wide temperature range, small size, high fiber count cables. Loose tube fiber optic cables are made of loose tubes filled with gel or absorbent powder to prevent water damage to the fiber optics. This type of fiber optic cable consists of several optical fibers inside a small plastic tube that is wound in turn around a central strength member and has a jacket.

- Ribbon cables: Ribbon cables offer the highest fiber count and fiber density of any other cable construction designed for outside plant (OSP) applications, and are 4 times the highest fiber count loose tube cables. It also enables large-scale splicing, where each 12-fiber ribbon can be spliced in one simple process. This facilitates quick installation and restoration of the network after a fiber optic cable is cut.

- Micro duct cables: Micro ducts are miniaturized plastic conduits that subdivide the internal duct space into smaller compartments into which micro cables can be blown, sprayed or pushed.

- Drop cables: Drop cables are the cables that run from distribution points to subscribers. Underwater optical cable: The casing material has good hydrolysis resistance and high strength. It is filled with optical cable paste to provide key protection for optical fibers.

- Armored fiber optic cable: Armored fiber optic cable is an outdoor fiber optic cable with protective armor wrapped around the cable core. Armoring is primarily used to protect fiber optic cables from animal bites, moisture, or other damage. Armored fiber optic cables are designed to withstand crush, pressure and rodent issues, and provide high flexibility and durability when used in harsh environments or confined spaces.

Application Scenario

Outdoor optical cables are used for backbone distribution between campus buildings, long-distance networking, core network and metropolitan area network (MAN) optical communication outdoor transmission lines, access network optical communication outdoor feeders and wiring, local area network (LAN) backbone networks and data centers.

How to Choose an Outdoor Fiber Cable?

The selection and use of outdoor optical fiber cables should be based on factors such as the transmission speed or capacity of the optical cable line, transmission distance, and transmission equipment requirements. Fiber optic cable for outdoor use should be selected according to the requirements of the installation, climate conditions, and special requirements of the laying environment. For example, when passing through a lightning strike area or an environment with a strong electric field nearby, consideration should be given to choosing a non-metallic optical cable. In some areas where rodents are more serious, rodents often bite optical cables, and anti-rodent optical cables should be selected.

Summary

Fiber optic cables for outdoor use are durable enough to withstand wind, sun, and cold. The outer sheath is thicker and has mechanical and environmental properties such as pressure resistance, corrosion resistance, and tensile resistance. It has a wide range of applications. Contact us at [email protected] if you want to know more.