The pipe hole resources of underground communication pipelines are the basic communication resources that operators are in short supply. Except for newly built roads and roads in development zones, the occupancy rate of pipe holes on other roads is generally high. Restricted by construction conditions, it is extremely difficult to expand the capacity of communication pipelines, and the current shortage of underground pipe holes for operators cannot be improved for a long time.

The Hole Occupancy metric is typically used to measure the hole resource usage for a pipe segment. The “pipe hole occupancy rate” is the ratio of “the number of sub-holes occupied by the optical cable” to “the number of sub-holes converted to the pipe group”. Usually, each sub-tube of the porous tube counts as one sub-hole, and the large-diameter single-hole tube is converted according to the number of sub-holes of the porous tube with similar outer diameter.

At present, the occupancy rate of pipe holes on many roads exceeds 90%, and some road sections even reach 100%. It is difficult to add optical cables to existing pipe holes, and it is urgent to reduce the pipe hole occupancy rate of existing pipes. Here are some ways to reduce the hole occupancy rate.

1. Using a textile sub-tube

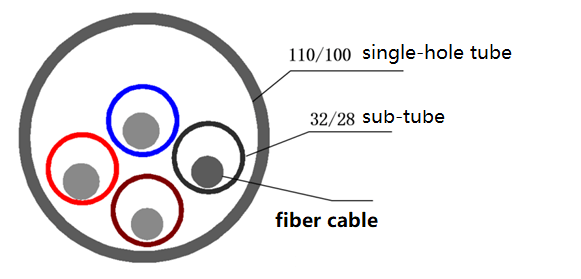

The pipe group combination of the underground communication pipeline generally includes some single-hole pipes with an inner diameter of about 100mm or 90mm. When laying optical cables in a single-hole pipe, multiple plastic sub-pipes should be laid to improve the utilization of pipe holes. In a single-hole tube with an inner diameter of 100mm, there are usually 4 sub-tubes of 32mm/28mm specifications, and one optical cable is laid in each sub-tube. In this way, 4 optical cables can be laid in a single-hole tube with an inner diameter of 100mm.

However, in this case, the cross-sectional utilization rate of the single-hole tube (Σ optical cable cross-sectional area/single-hole tube cross-sectional area) is too low, only about 10%.

Textile sub-tubes are typically soft, ribbon-like sub-tubes sewn from polyester and nylon mesh with a low coefficient of friction and contain traction cords. A textile sub-pipe that is put on at one time is called a belt. There are 3 different combinations for each textile sub-tube, with 1 hole, 2 holes, and 3 holes, which can put 1, 2, and 3 optical cables respectively. The use of textile sub-tubes can increase the number of optical cables laid out in each single-hole tube several times, thereby reducing the tube hole occupancy rate accordingly. The tensile strength of the textile sub-tube exceeds 1000kg, which is several times that of the ordinary pipe optical cable. Directly laying or removing the optical cable in the tube hole of the existing optical cable will easily cause damage to the optical cable.

However, the application of textile sub-tubes faces the following problems: (1) the price is high (2) when laying optical cables in a single-hole tube, the sub-tubes are often not laid out, but the cables are directly stacked; in this way, the use of textile sub-tubes cannot increase the number of optical cables that the tube hole can carry. This is also the reason why the textile sub-tube has not been used on a large scale.

2. Using microtubules and microcables

Compared with laying ordinary optical cables, under comparable conditions (optical cables are easy to lay, replace and manage), the solution of manually laying micro-pipes in the metro pipeline and blowing the micro-cables through the micro-pipes will occupy the pipe holes. Compared with the laying of ordinary cables, the rate can be reduced by nearly 1 times. However, the micro-cable needs to be laid by air blowing, and the construction unit is required to have the cable-blowing equipment; in addition, due to the poor mechanical properties of the micro-cable, its safety is affected to a certain extent in places that should be touched by personnel such as hand holes.

3. Using a compact fiber optic cable

A compact optical cable is a high-density optical cable whose mechanical properties meet the requirements of ordinary optical cables, but the outer diameter is much smaller than that of ordinary optical cables with the same number of cores. Unlike micro-cables, compact fiber-optic cables can be routed just like ordinary fiber-optic cables, without the need to be routed in specific micropipes.

For the same type of optical cable, its “minimum allowable tensile force” index is mainly proportional to the cross-sectional area of the optical cable. In order to achieve the minimum tensile performance of ordinary optical cables, the minimum outer diameter of compact optical cables is usually equivalent to that of ordinary optical cables, which is about 9.5mm. The minimum number of cores for compact optical cables is usually not less than 96 cores.

Due to the small cross-sectional area, using a compact optical cable in a single-hole tube can reduce the occupancy rate of the tube hole by more than 50%. For example, usually about 10 ordinary optical cables with various outer diameters can be mixed in each perforated tube. If compact optical cables are used for large-core optical cables, each perforated tube can be mixed with more than 20 hybrid optical cables with various outer diameters. .

4. Combined small count fiber optic cables

Multiple small-core-count optical cables that end at the same location (the same or adjacent ODF, the same optical cross) and the same route, if these optical cables are at the same optical cable level, multiple small-core-count optical cables can be combined into one large core count fiber optic cables to reduce the occupancy of pipe holes. The optical cable layer here refers to: the core layer, backbone convergence layer, common convergence layer, and base station access, backbone section, distribution section, and drop-in section of the access layer, etc., optical cables at different layers can also be combined if the origin, destination, and route are the same.

The number of cores of the small-core-count optical fiber cable is relative to the number of cores of the newly released optical fiber cable, and there is no strict core number requirement. However, from the perspective of control engineering investment, the number of cores of a single fiber optic cable to be removed should not exceed 48 cores. Among the existing laid optical cables, 24 cores and below account for more than 60%. Even if 10% of them can be combined, it can greatly alleviate the general shortage of tube hole resources.

5. Reduce the length of new fiber optic cables by reusing existing fiber optic cable cores

Although the occupancy rate of the existing pipe holes is very high, the fiber core utilization rate of the in-use optical cable is very low. For example, the overall fiber core utilization rate of a prefecture-level city of operator M is only 27.7%, while the overall fiber core utilization rate of operator T in the same region is over 50%. By utilizing the spare cores of the existing fiber optic cable, the M operator can reduce the length of cable deployment, thus reducing the occupation of tube-hole resources.

For example, the current inbound customer access usually directly deploys 12-core optical cables from the junction box (or computer room) to the inbound customer. Since each user actually needs only 1 to 2 cores, this leads to the loss of the fiber core of the customer access optical cable. Usage is too low. When adding a guest user, if only 2 to 4 cores are allocated to the user, and multiple users share one optical cable, the utilization rate of the fiber core of the guest access optical cable can be greatly improved.

Summary

The use of compact optical cables or micro-tubes and micro-cables for the newly added optical cables can reduce the occupation of the remaining tube hole resources by the optical cables. It will be fully occupied. Therefore, for the road sections with high occupancy rate of pipe holes, before adding optical cables, the original optical cables should be properly reconnected and adjusted to ensure that after the new optical cables are added in this phase of the project, there are also a certain number of spare sub-holes in the tube group.

In the section where the tube hole occupancy rate reaches 100%, the textile sub-tube can be laid out through the gap of the original tube hole, and then the compact optical cable with enlarged core count can be laid out from the textile sub-tube, and the original multiple optical fiber cables with small core count can be combined. , and then add optical cables after freeing up the tube hole resources.

Of course, the design scheme also has a great influence on the occupancy rate of the pipe holes, so it must be planned well in the early stage.

The pipe holes of the underground communication pipeline are almost full. How to lay the new optical cable? The above is the answer.