Bulk Fiber Optic Cables

- Price Advantage for Bulk Orders

- Full Customization & Low MOQ accepted

- Quality Materials

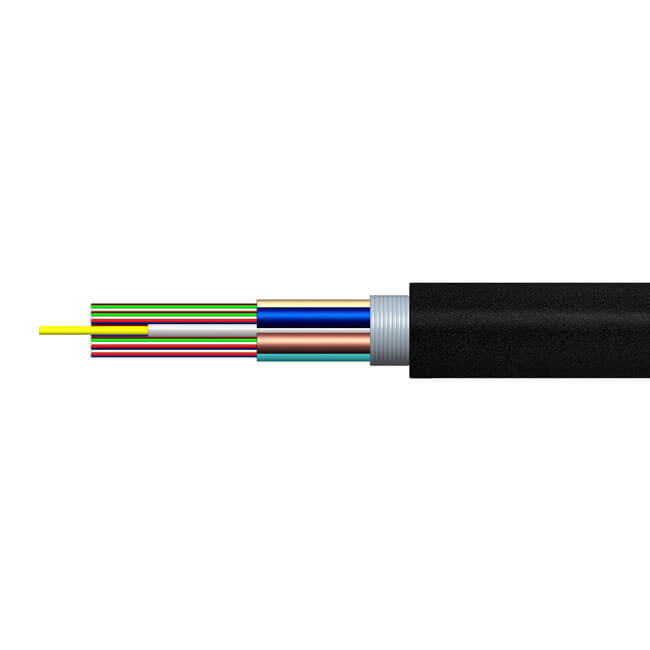

Fiber cables armored with steel tape, aluminum tape, steel wire and others

Air blown fiber and micro blown fiber cable for fast installation

Self -supporting aerial fiber optic cable with hanging wire and figure 8 shapes

Fiber optic cables that is water tight and used underwater, rivers or shores

Fiber optic cables installed overhead with poles and fittings

ADSS cable with all different spans, cores, sheath and more

Direct buried fiber optic cable can be directly buried in the ground

Duct fiber optic cable is installed in the form of ducting

Fiber cables with tight buffered fiber core, mostly for indoors and distributions

Connect end user and distribution network with FTTH access or drop cable

Indoor armored fiber cable often consists of tight-buffered or loose-buffered with strength members and an inner jacket

Fiber breakout cable is also known as fan-out fiber cable. It is a type of fiber optic cable that contains numerous simplex fibers, each with its own jacket, and then encased by a single common jacket

Duplex fiber optic cable enables bidirectional data transfer. It’s a good choice for applications such as telecommunications as well as workstations, Ethernet switches, fiber switches and servers, and backbone ports

Simplex fiber optic cable only carries one ray of light at a time, it’s better for long-distance transmissions

Mining fiber cable is a special application of fiber optic cable in the field of optical communication. It is a communication optical cable that is professionally used in the mining industry.

Tactical fiber cable is designed with protection. It has rugged construction for the highest possible survivability and is ideal for use in harsh environments where deployment and retrieval are required.

- Connector Configuration: LC, SC, ST, FC, MTRJ, MTP, APC, UPC and more.

- Jacket Type: Indoor/Outdoor, Armored, Aerial, Tactical, Zip Cord, Tight Buffered and more.

- Jacket Rating: Plenum & Riser Rated (OFNR / OFNP)

- Modality: Multimode OM1, OM2, OM3, OM4 & Singlemode OS2

- Any Length, Any Fiber Count: 1, 2, 4, 6, 8, 12, 24 & 48 Fiber Strands (More available)

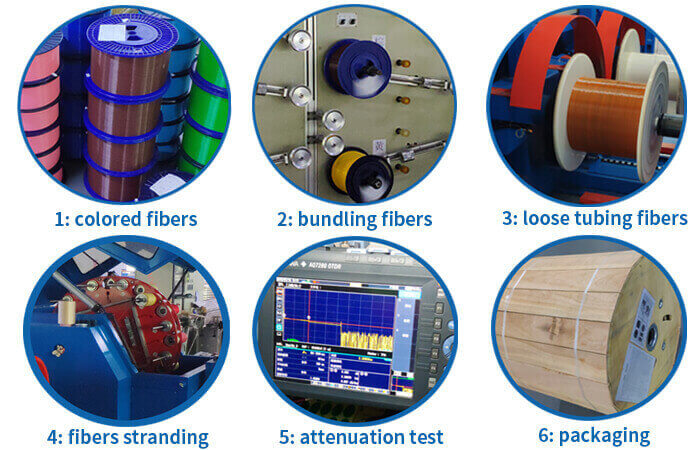

Fiber Optic Cable Manufacturing Process

The manufacturing process of fiber optic cables consists of several essential steps:

- Coloring Fibers: Applying color codes to distinguish individual fibers.

- Bundling Fibers: Grouping fibers together to form a cable core.

- Loose Tubing Fibers: Placing the bundled fibers within protective tubing.

- Fibers Stranding: Arranging the fibers in a specific configuration.

- Attenuation Test: Assessing the signal loss characteristics of the fibers.

- Packing: Preparing the finished fiber optic cables for shipment.

Please note that actual production in a fiber cable factory can be more intricate, but these steps provide a simplified overview for better understanding.

Have Trouble In Finding The Right Fiber Cable Or Need Further Help?

We would be happy to help you. Please provide us with more details about your application and we will recommend products that are suitable for your fiber optic cabling needs.