Submarine Fiber Optic Cable

Subsea / Submarine fiber optic cable is often laid in oceans and rivers. It has a large transmission capacity and a long length. Underwater fiber optic cable is suitable for long-distance transoceanic communication systems. As one of the most professional submarine/underwater cable manufacturers, we specialize in designing, manufacturing submarine fiber optic cable, and providing customized services for our customers!

- Safe and stable, strong anti-interference ability, good confidentiality performance

- Competitive price

- OEM Service can be provided

- 100% quality assurance

Underwater Fiber Optic Cable

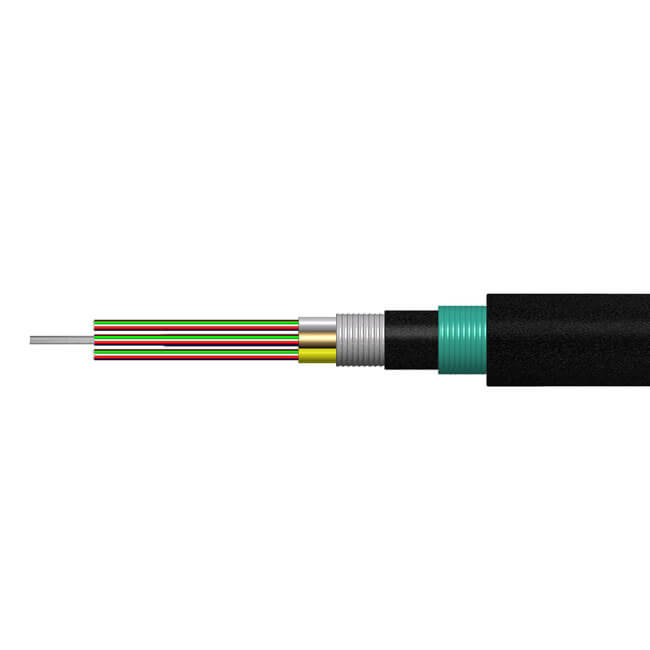

Subsea / Submarine fiber optic cable, also known as submarine communication cables, are wires wrapped with insulating materials, which are generally laid in deep or shallow seas, or in rivers, to establish telecommunication transmission between countries. The insulation structure of undersea cables is basically the same as that of the land cable, but because the application environment of the underwater fiber optic cable is more complex and harsh than that of the land, it has layers of armor protection to protect the submarine cable from damage. The basic structure of submarine optical cable is: polyethylene layer, polyester resin or asphalt layer, steel strand layer, aluminum waterproof layer, polycarbonate layer, copper or aluminum tube, paraffin, alkane layer, optical fiber bundle, etc.

Most Required Submarine Fiber Optic Cable

Subsea cables can be divided into light weight cable, light weight protected cable, single armored cable, double armored cable, and rock armored cable and other structures. Different types of underwater optical cables correspond to different specific use scenarios and mechanical strength requirements.

Submarine Fiber Optic Cable Applications

Submarine communication cables are mainly used for long-distance communication networks, usually used in more important occasions such as long-distance islands, cross-sea military facilities, etc. The steel wire armored underwater fiber optic cable can also be installed in all external environments including underwater, climbing, and direct burial. Undersea cables also serve as dedicated communication and control cables for telecommunications and applications in the oil and gas industry.

direct burial

underwater

climbing

Your Trusted Submarine Fiber Optic Cable Manufacturer

Innovation, Quality, Service and Responsibility

- Our R&D team, skilled workers, advanced machines, and modern factories can provide our customers with outstanding quality service.

- On the flexibility

- High-quality control standard

- Plenty of Certificates of products and customs

- Professional expert team

- 24/7 Availability

You Ask, We Answer

Yes. We will have a dedicated process engineer to interface with you to understand the specific situation and give our production advice.

Yes. We have Fujikura, Corning SMF 28e, and other brands fiber to choose from.

Yes. As long as we confirm the Pantone color code, we can produce the sheath color you request.

Yes. We can print company information or logos on fiber optic cables upon request.

Under 100 km, it takes 4-5 days to produce. under 500 km, it takes 7-10 days to produce.

The minimum order quantity of fiber optic cable is 1km. Because the outside diameter needs to be adjusted before producing.

This process will waste dozens of meters of raw material.

All fiber optic cables will come with a test report. If you encounter any quality problems, we replace them with new ones free of charge.

We have a special laboratory for high temperature, salt spray and vibration testing.

A supplier provides products,

but we care about your business.

If you do not find submarine fiber optic cables that can meet your requirements, please contact us as we might have a solution available.